Auxiliary positioning mechanism for taping machine

A technology for assisting positioning and wrapping machines, applied in the direction of coil manufacturing, etc., can solve the problems of inconsistent tension, ineffective loop coil force, loose paper, etc., and achieve the effect of avoiding loose packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

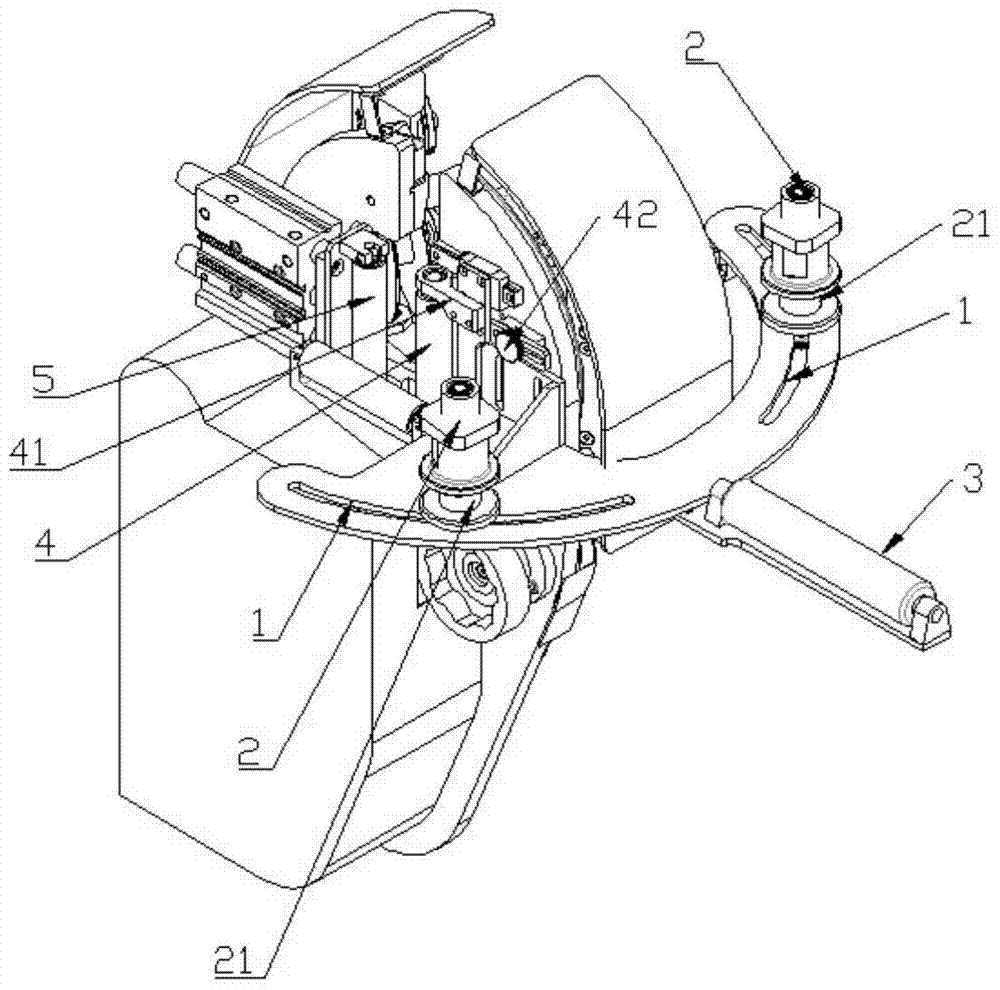

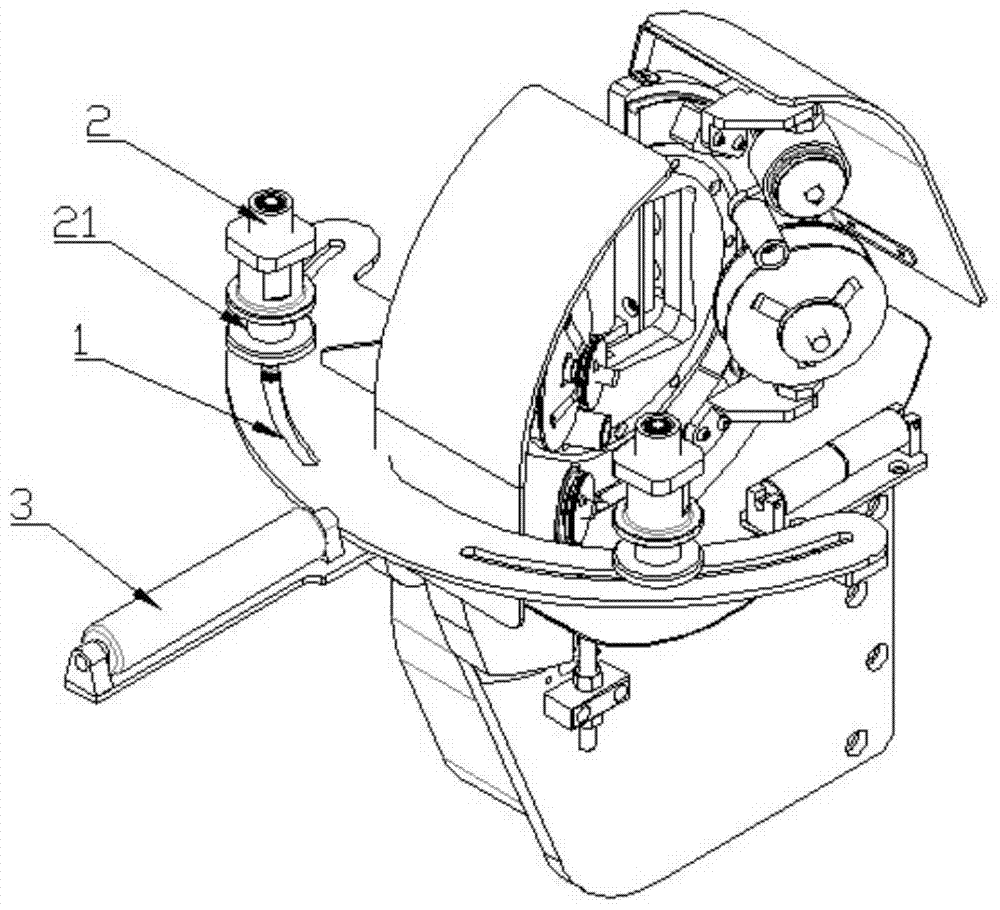

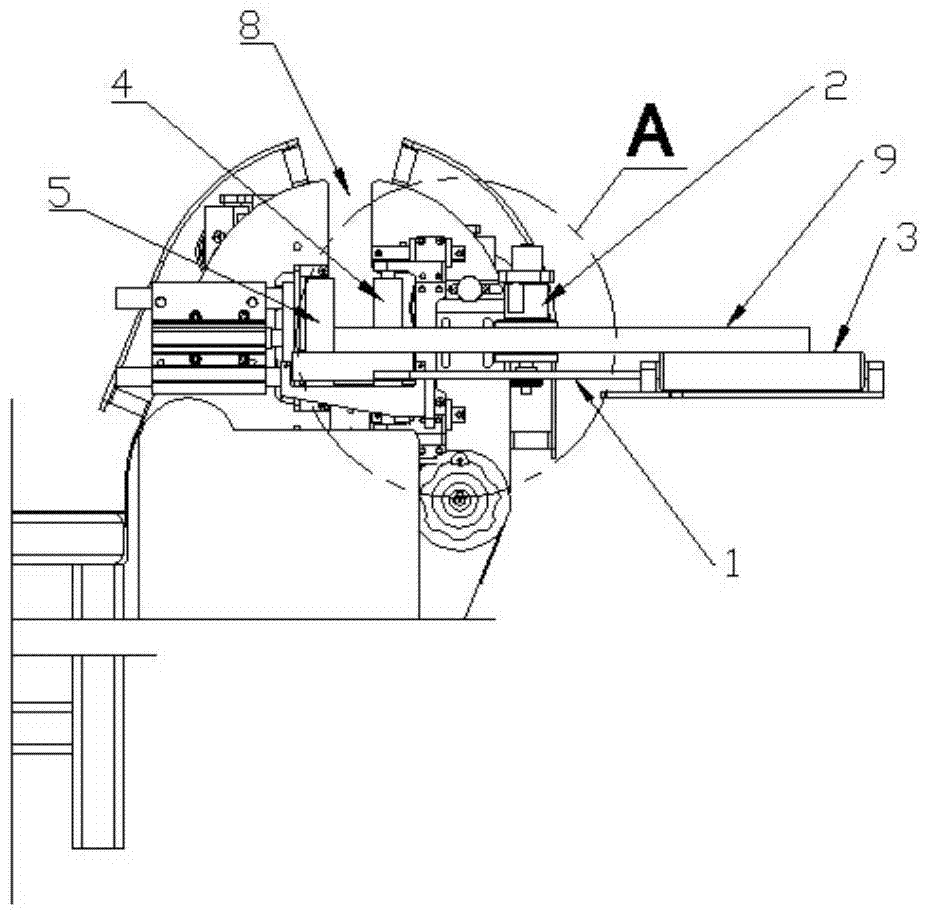

[0025] Such as Figure 1-Figure 5 As shown, the auxiliary positioning device of the strapping machine provided by the present invention includes a track 1, an adjustment wheel 2 and a horizontal support roller 3 arranged outside the packaging channel 8 of the strapping machine, wherein:

[0026] The track 1 is preferably arc-shaped, arranged horizontally, and fixed on the side of the packaging channel 8 in a liftable manner;

[0027] There are at least two groups of adjustment wheels 2, which are slidably arranged on the track 1 and can be fixed on the track 1. The shafts of the adjustment wheels 2 are arranged vertically, and each group of adjustment A horizontal annular gap 21 is formed between the wheels 2 for engaging the annular coil 9;

[0028] There is at least one horizontal support roller 3 , which is fixedly connected with the track 1 .

[0029] When in use, one side of the annular coil 9 passes through the packaging passage 8, and the other side is supported by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com