Strain producing long chain dibasic acid, and application thereof

A long-chain dibasic acid and a technology for producing strains, which are applied in the field of microorganisms to achieve good market application prospects, wide applicability, and high transformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] 1. Preparation of dibasic acid samples: After the fermentation, adjust the pH value to 3.0 with 6mol / L HCl in a 500mL Erlenmeyer flask, add 120mL ether to each bottle, shake it 100 times, let it stand for more than 30min, let it stand for stratification, and take out 40mL ether The extract was added to a 100mL beaker, and the ether was removed to obtain a white solid, which was then measured for dibasic acids.

[0049] 2. Determination of the output of dibasic acid: dissolve the extracted dibasic acid with neutral hot ethanol (95%), add a drop of phenolphthalein, titrate with standard NaOH solution, record the volume of NaOH consumed, and calculate DC 12 Yield.

Embodiment 1

[0051] The Candida tropicalis CAT N145 of the present invention has been verified by subculture experiments, and the colony morphology and the ability to produce long-chain dibasic acids have no obvious changes after multiple subcultures. It can be seen that the passage stability of Candida tropicalis CAT N145 of the present invention is good.

Embodiment 2

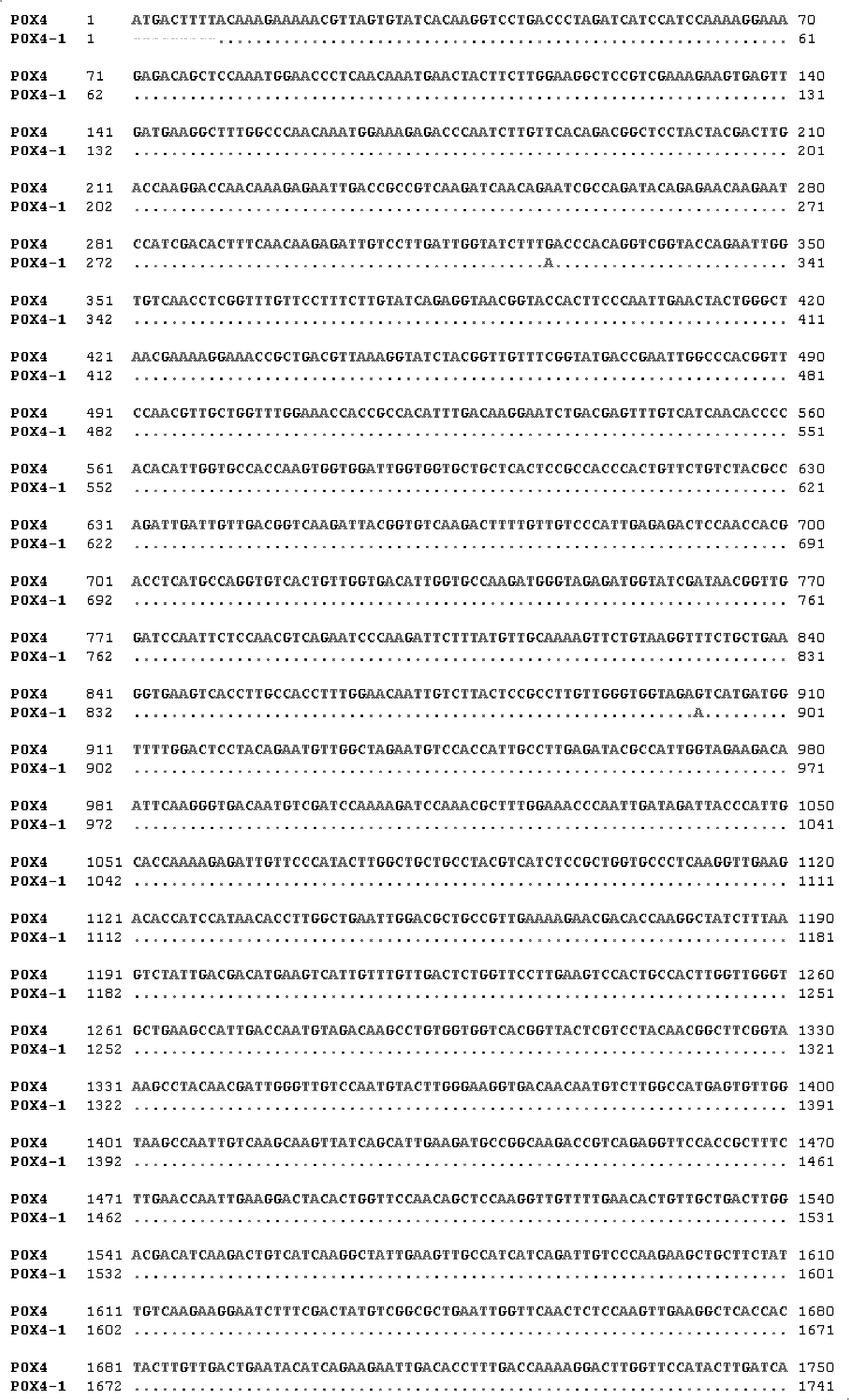

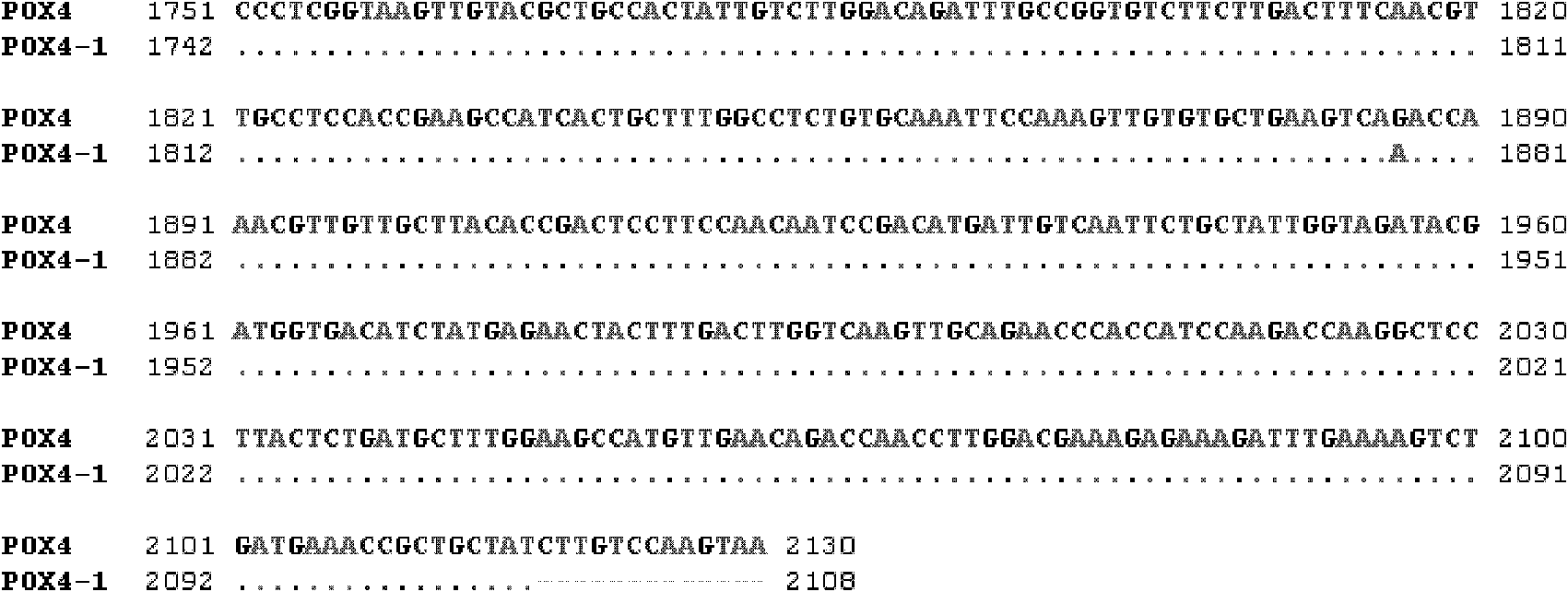

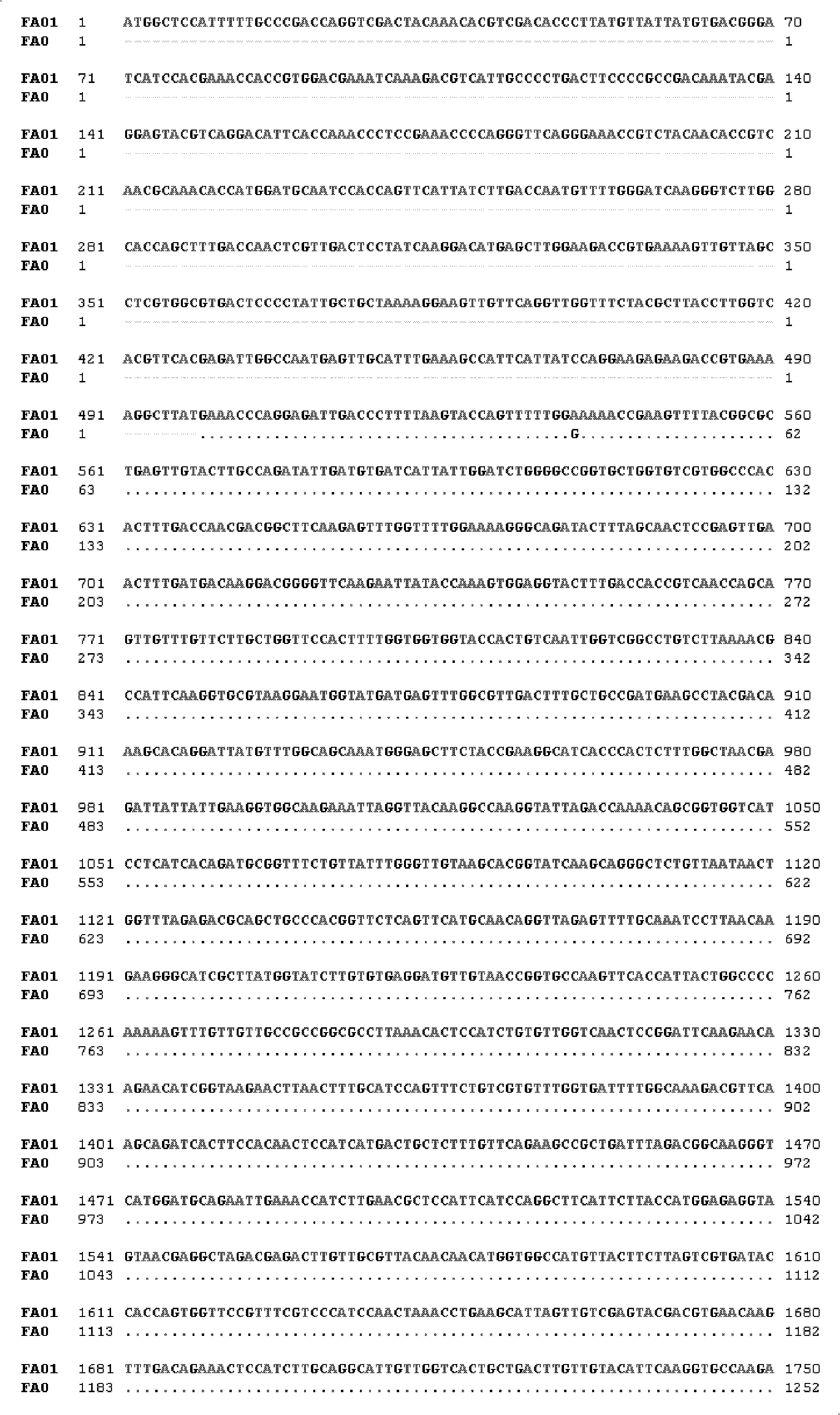

[0053] Genomic DNA of the strain was extracted using the Yeast DNAiso Kit kit from TaKaRa Company, and PCR amplification was performed using the genome as a template. The enzyme used in PCR was Pfu enzyme from Biomad Company, and the PCR system and conditions were operated according to the instructions.

[0054] PCR amplification of pox4, fao and cyp52a18 genes, the primers used are shown in the table below.

[0055] pox4s AACGACATAATGACNTTNAC

[0056] pox4a-TTATTTGGACAAAATAGCAG

[0057] faos AAAGGCDTATGAAWCCCAGG

[0058] faoa CATTCAAACAATCTACCATC

[0059] a18s GyGCTGCTCCwrTCACAAAC

[0060] a18a CTArTCrAwCTTGACAATAG

[0061] After PCR was completed, 2 μL of dNTP and 0.5 μL of rTaq enzyme were added, and reacted at 72° C. for 30 min. The PCR product was recovered using the Agarose Gel DNA Purification Kit from TaKaRa Company. The recovered product was connected to the pMD18-T vector, and the connection operation was performed according to the product manual. The ligation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com