Preparation method for flame-retardant and weather-resistant modified ABS resin

An ABS resin and a manufacturing method technology, applied in the field of plastic alloys, can solve the problems of poor flame retardant performance, affecting the application of ABS resin, mechanical properties and bad appearance changes, etc., and achieve the effect of improving flame retardant and weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

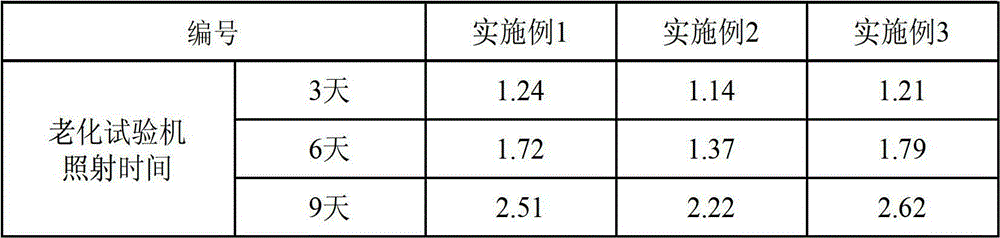

Embodiment 1

[0016] Example 1: 70 parts of ABS resin, 30 parts of ASA resin, 20 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 0.5 part of antioxidant 1010, 0.3 part of magnesium stearate, 0.3 part of UV-P, Take 0.3 part of light stabilizer 770 and 7 parts of styrene maleic anhydride graft copolymer.

Embodiment 2

[0017] Example 2: 65 parts of ABS resin, 35 parts of ASA resin, 18 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 0.3 part of antioxidant 626, 0.3 part of antioxidant 1076, ethylene bisstearamide 0.3 parts, UV-326 0.3 parts, light stabilizer 770 0.3 parts, and methyl methacrylate-butadiene-styrene copolymer 8 parts.

Embodiment 3

[0018] Example 3: 70 parts of ABS resin, 30 parts of ASA resin, 20 parts of tetrabromobisphenol A, 4 parts of antimony trioxide, 0.3 part of antioxidant 626, 0.3 part of antioxidant 1076, 0.3 part of magnesium stearate , 0.3 parts of ultraviolet absorber UV-326, 0.3 parts of light stabilizer 770, and 7 parts of ethylene-acrylate-maleic anhydride copolymer.

[0019] The manufacturing method of the above embodiment: Weigh the materials according to the weight parts of the materials and then add them to the high-speed mixer, mix them evenly and add them to the twin-screw extruder. The temperature settings of the eight temperature zones in the extruder are respectively 190°C, 200°C, 210°C, 220°C, 230°C, 230°C, 220°C, 220°C, 220°C, the main engine speed is 300 rpm, the extruded strip is cooled and hardened through the circulating water tank, and then enters the pelletizer for granulation and cutting The output material of the granulator enters the vibrating screen, and the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com