Friction-driving trolley type conveying device

A technology of friction drive and handling device, which is applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., which can solve the problem of requiring a very large floor area and achieve the effect of light weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

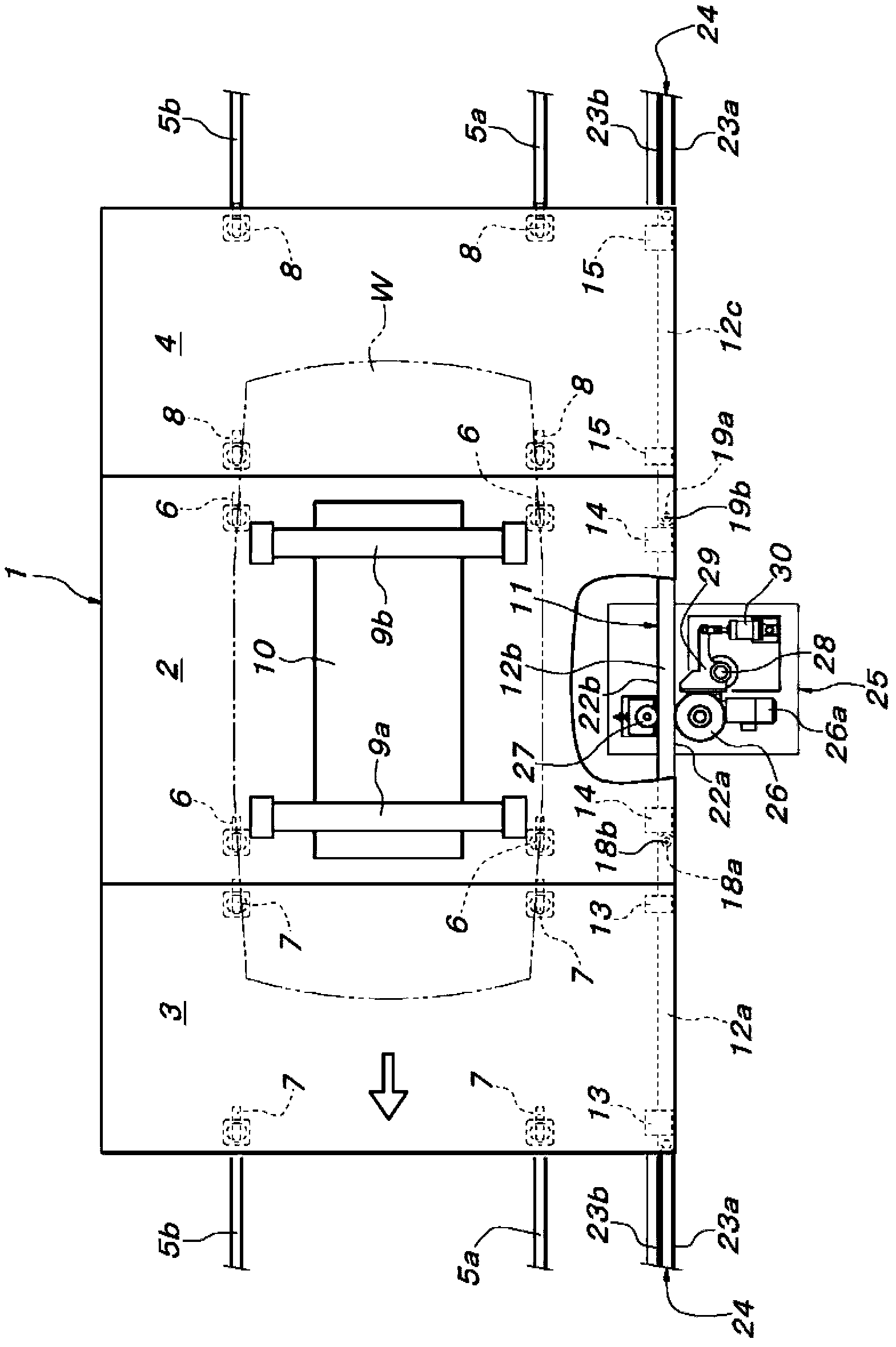

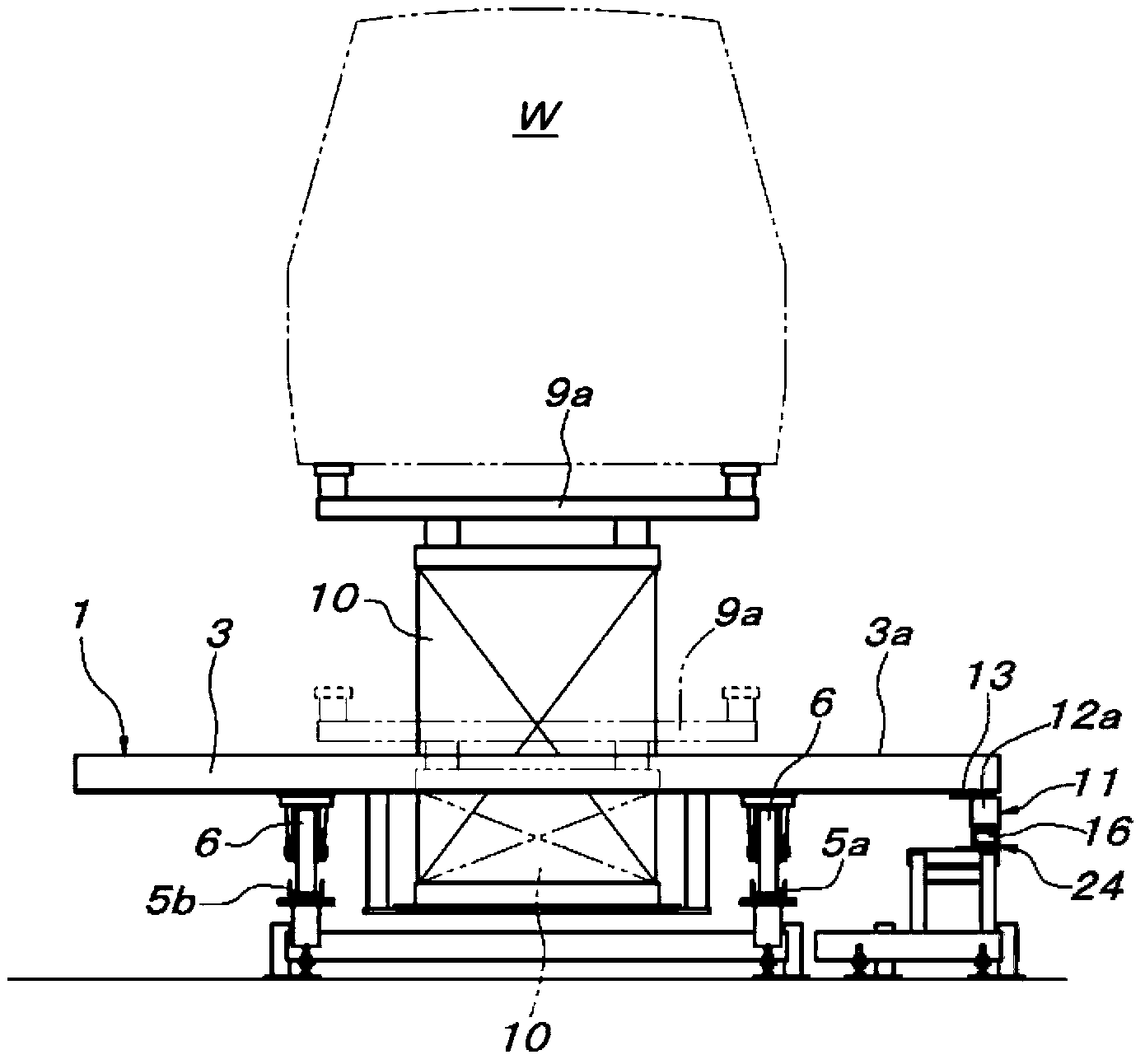

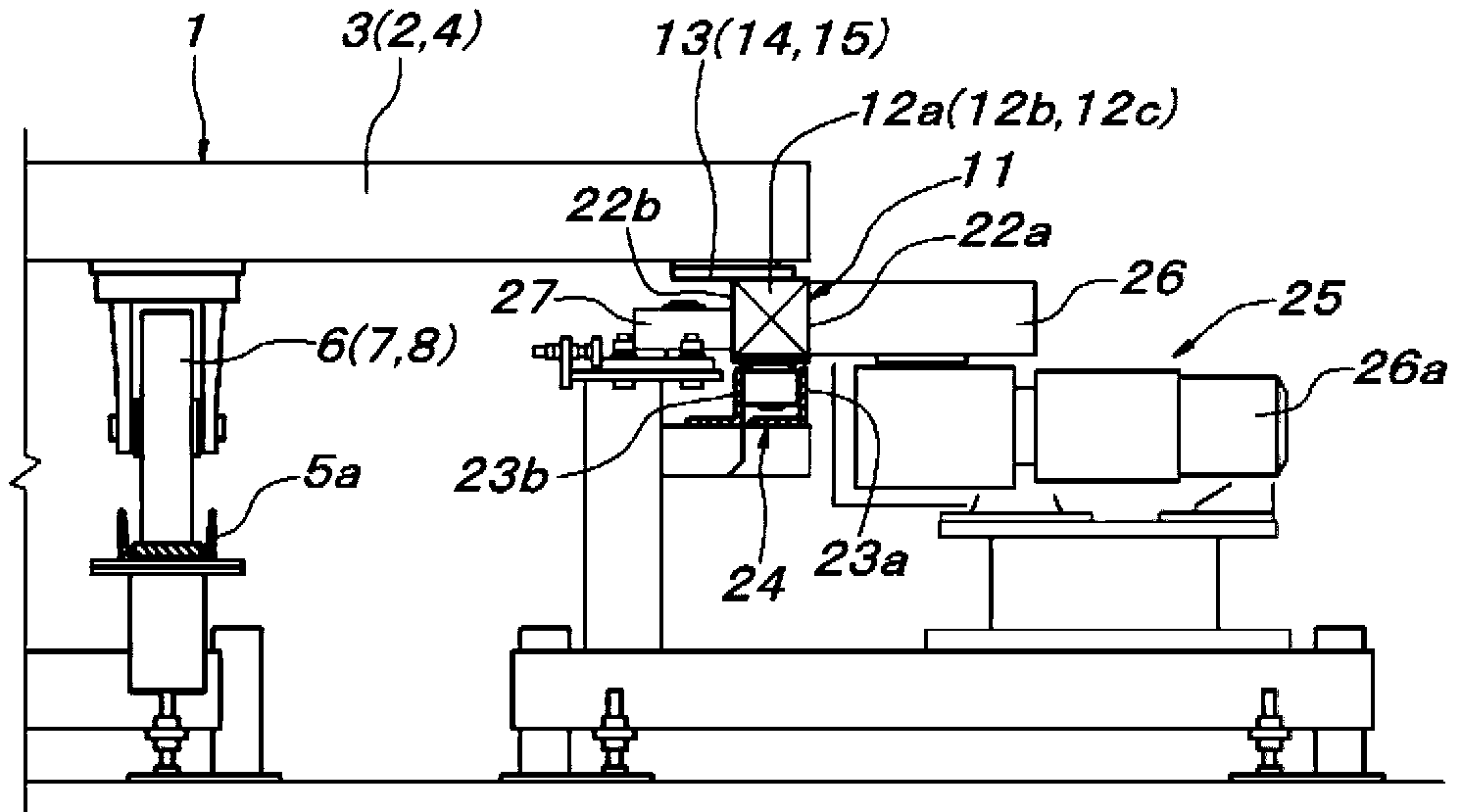

[0093] Moving trolleys such as Figure 1 ~ Figure 4B As shown, it is composed of a central trolley unit 2 located in the center of the traveling direction, a front trolley unit 3 and a rear trolley unit 4 adjacent to the front and rear. Each trolley unit 2-4 is equipped with a left and right pair of front and rear free wheels 6-8, which can rotate on a left and right pair of rails 5a, 5b laid along the travel path. The central carriage unit 2 is provided with a pair of front and rear object support platforms 9a, 9b, and an elevating drive device 10 that drives the two object support platforms 9a, 9b in parallel.

[0094] The structure of this lifting drive device 10 is the structure of the prior art, so the illustration and description of the structure are omitted. A lifting drive device consisting of a pressure cylinder unit or a motor-driven screw jack, a chain that can be pushed up and down freely, etc. The elevating drive device 10 is installed so as to protrude from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com