Mold monitoring method based on FAST-9 image characteristic rapid registration algorithm

A FAST-9, image feature technology, applied in image analysis, image data processing, calculation, etc., can solve problems such as poor robustness, easy to be affected by on-site lighting, noise, shadow and mechanical vibration, and poor real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

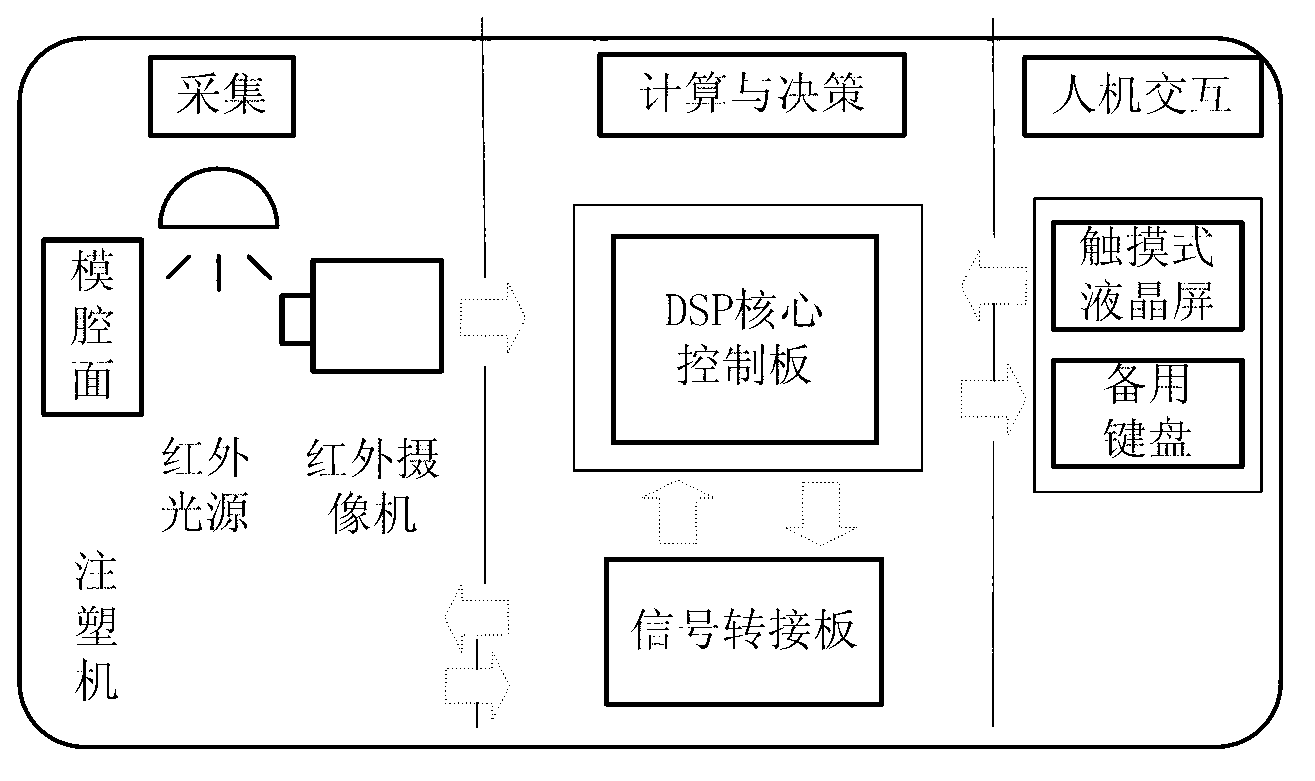

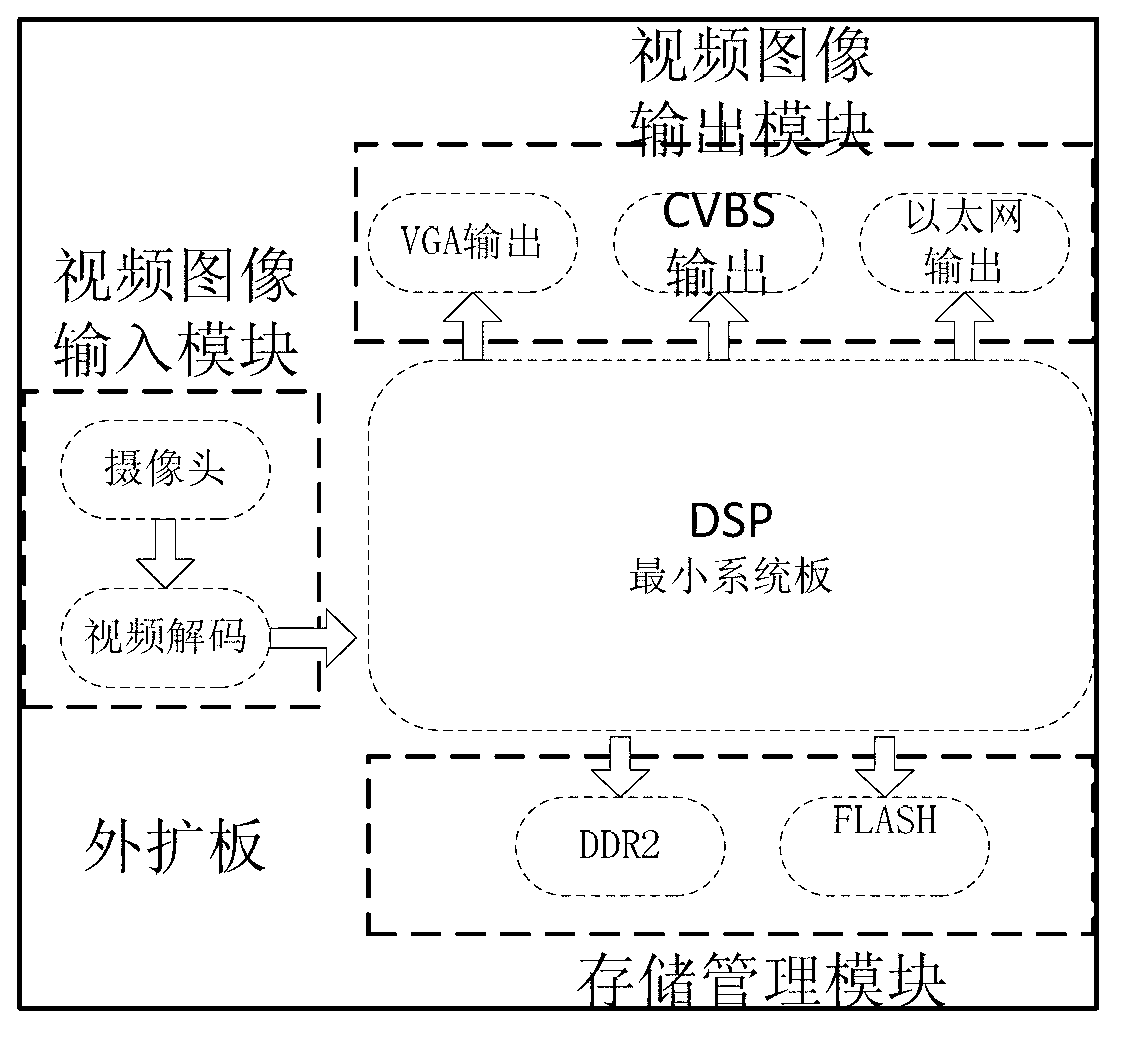

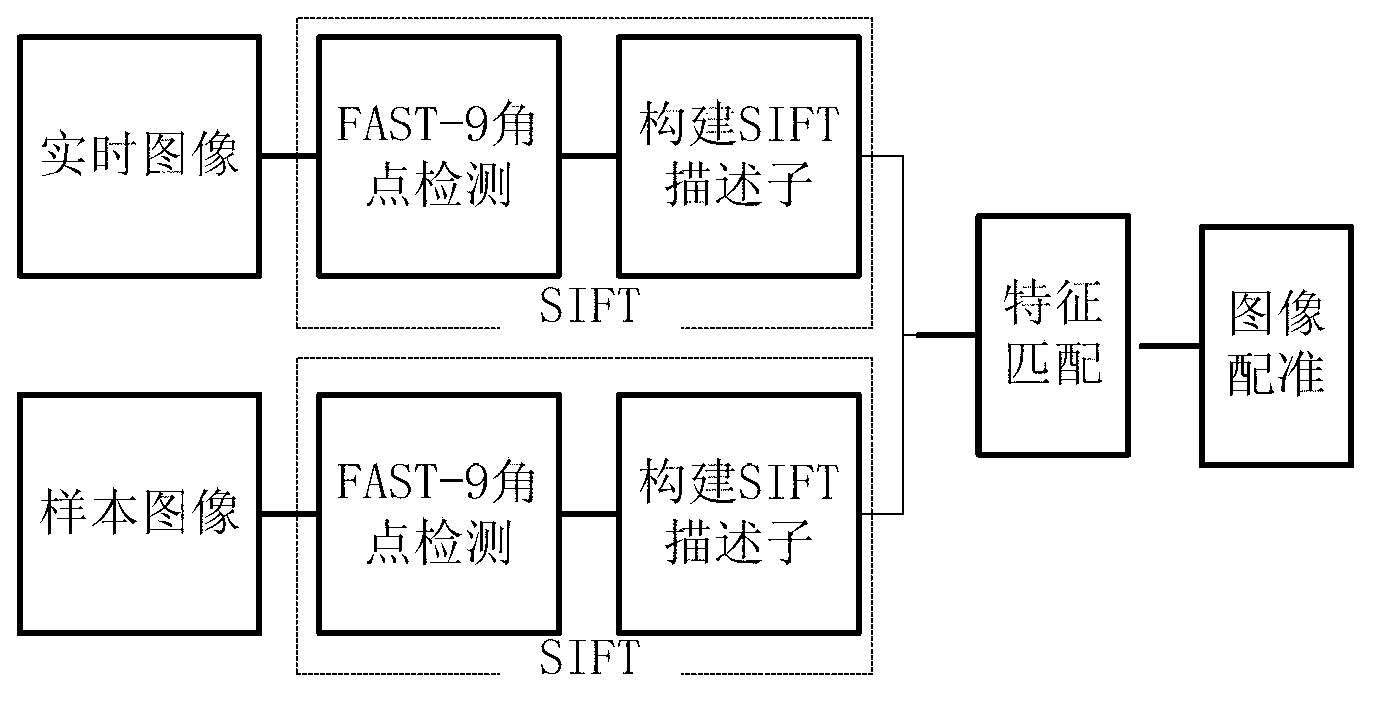

[0049] refer to Figure 1 to Figure 5 , a mold monitoring method based on the fast registration algorithm of FAST-9 image features. In a complete mold molding cycle, when the injection molding machine runs to the mold opening position, the output signal triggers the mold monitoring system, and the system monitors the mold cavity through the camera. Continuous image acquisition, while collecting the working status of the injection molding machine such as mold opening in place, thimble in place, safety door, etc. through the signal adapter board, and then the DSP core control board analyzes and processes the monitoring image to eliminate noise, light, shadow and mechanical vibration on site. effects of other factors. Determine whether there is any defect in the molded product by comparison, if there is any abnormality, alarm, otherwise continue. After the thimble of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com