Tool for cleaning drilling burr

A tool and burr technology, applied in the field of drilling burr cleaning tools, can solve the problems of difficult to control the position of the countersink, speed up the countersink, cutting transition, etc., and achieve the effects of improving processing safety, improving processing accuracy and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

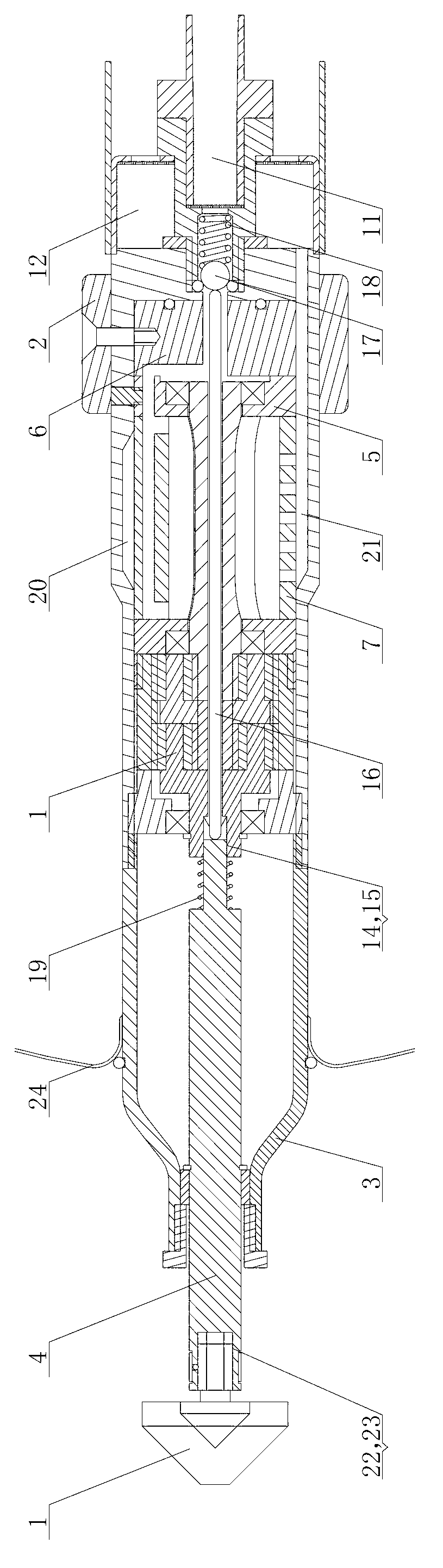

[0063] Such as figure 1 and figure 2 As shown, the drilling burr cleaning tool includes a countersink 1, a knob 2 and a casing 3; the casing 3 is provided with a main shaft 4, a fixed piece 5, an adjusting piece 6 and an air motor 7;

[0064] The fixed piece 5 separates the shell 3 into two parts; the fixed piece 5 is provided with an eccentric air inlet 8 at a position deviated from its central axis; the adjusting piece 6 and the fixed piece 5 are coaxially arranged and attached to each other; The air intake hole 9 extending in its axial direction; the adjusting piece 6 is provided with an air inlet 10; one end of the air inlet 10 communicates with the air inlet 9, and the other end can be adjusted when the adjusting piece 6 is rotated to a predetermined position in the circumferential direction. communicate with the eccentric air inlet 8;

[0065] The air inlet 10 is a groove provided on the side wall where the adjusting piece 6 and the fixing piece 5 are bonded.

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com