Forging method of aluminum or aluminum alloy

A technology for aluminum alloys and forgings, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of low strength, lowering the precision and yield of forging products, secondary deformation, etc., and achieve good structure and performance. The effect of high yield and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The blank is made of 5052 aluminum alloy material, and the size of the blank is 50×43×5 (mm).

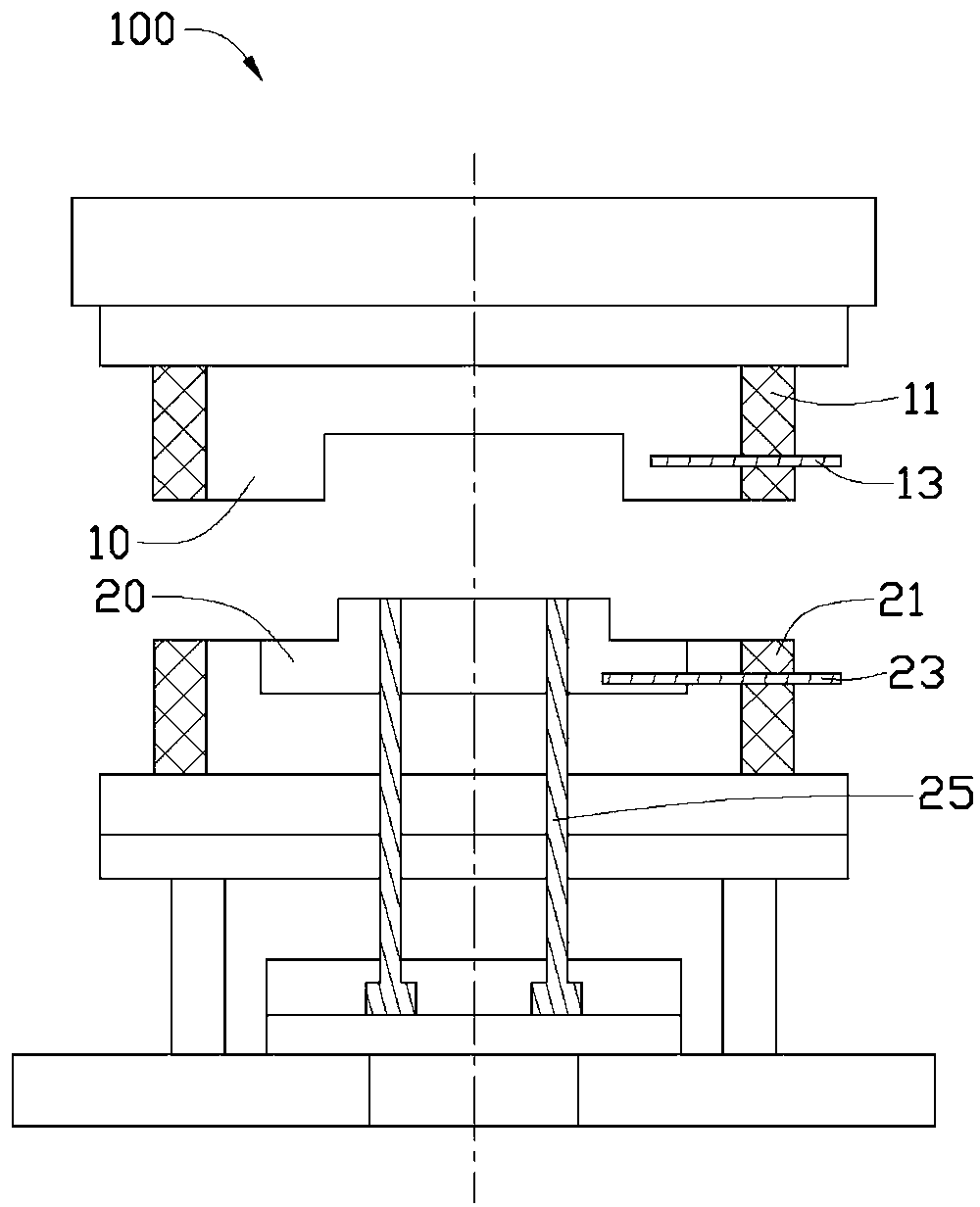

[0032] Set the temperature of the upper die 10 to 360-380°C, set the temperature of the lower die 20 to 160-180°C, and set the temperature difference between the upper and lower dies to 100-200°C, use a hydraulic press to impact or squeeze the forging die 100, and the forging time 1-2min.

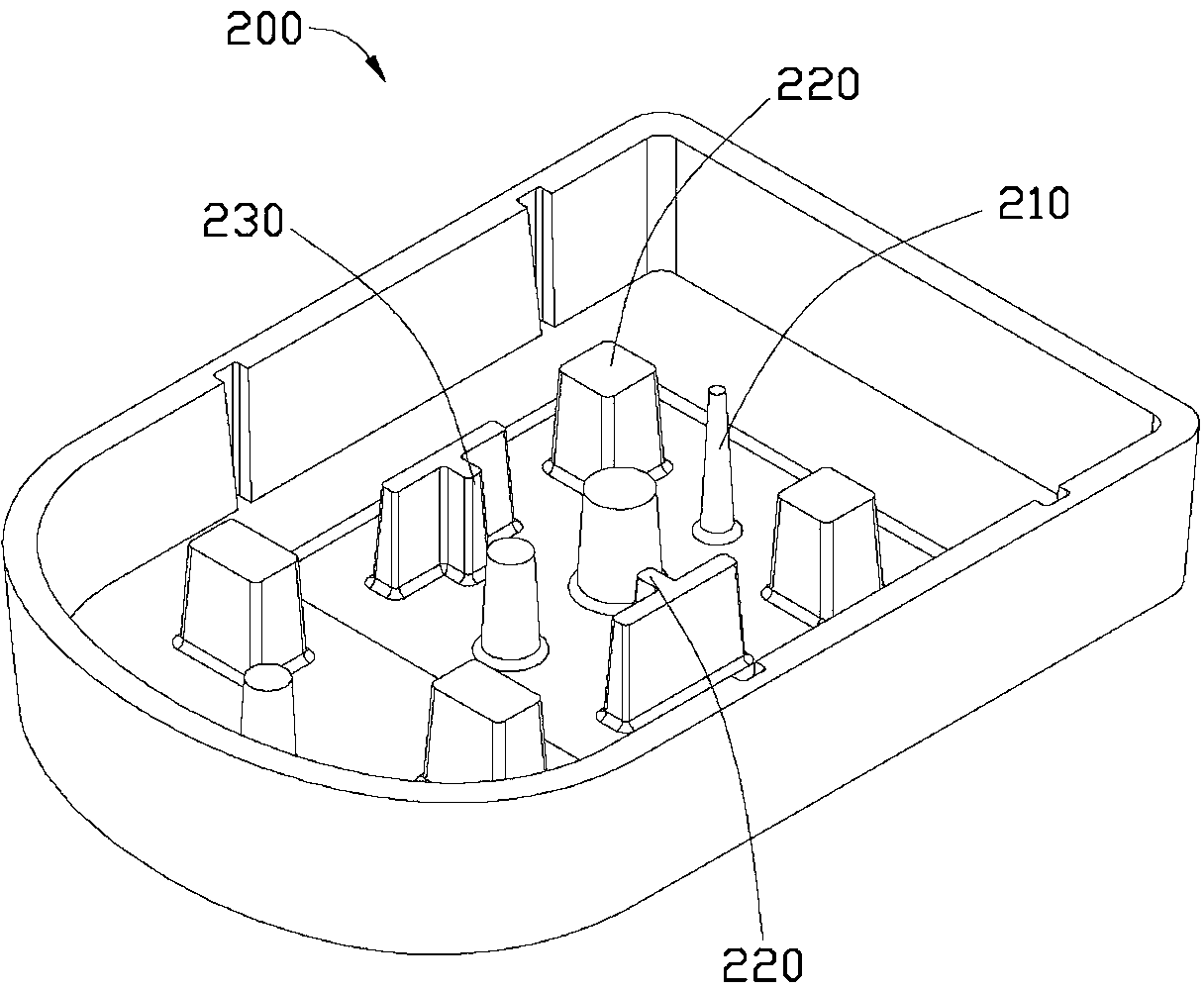

[0033] see figure 2 , the forging 200 is forged with a plurality of cylindrical bosses 210, square pillar bosses 220 and ribs 230, wherein the minimum size of the cylindrical bosses 210 can be 1mm 2 (bottom area)×10mm (height), the size of the rib 230 is 1.3mm (width)×7mm (height).

[0034] After the forging in this embodiment is demoulded, neither the cylindrical boss 210 nor the square pillar boss 220 on the forging is deformed, and the dimensional accuracy is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com