Tire protection cover spin-edge machine

A cover spinning and tire technology is applied in the field of tire protection cover hemming machines, which can solve the problems of low processing efficiency, no guarantee, uneven quality, etc., and achieve the effects of ensuring hemming quality, simple and compact structure, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

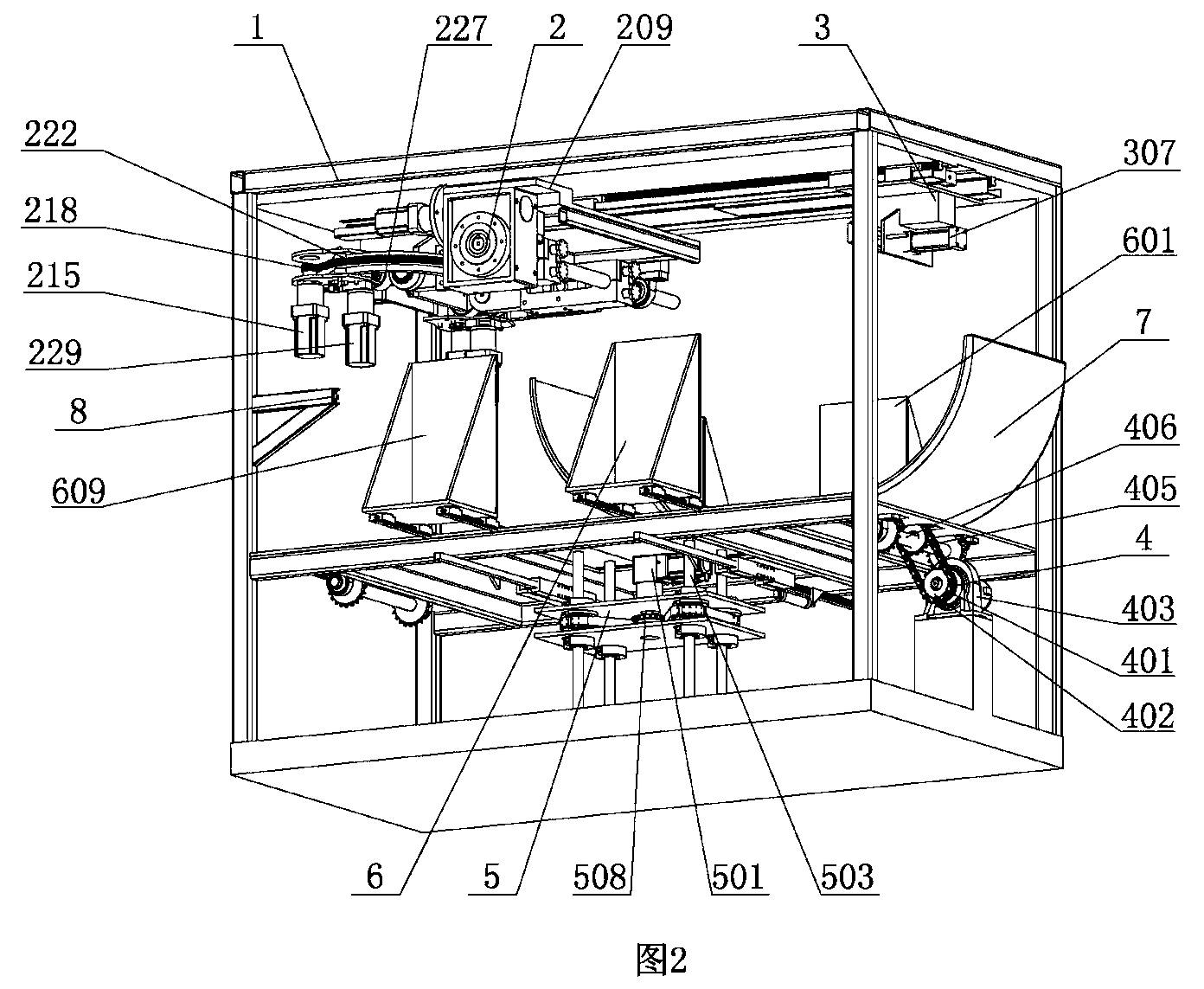

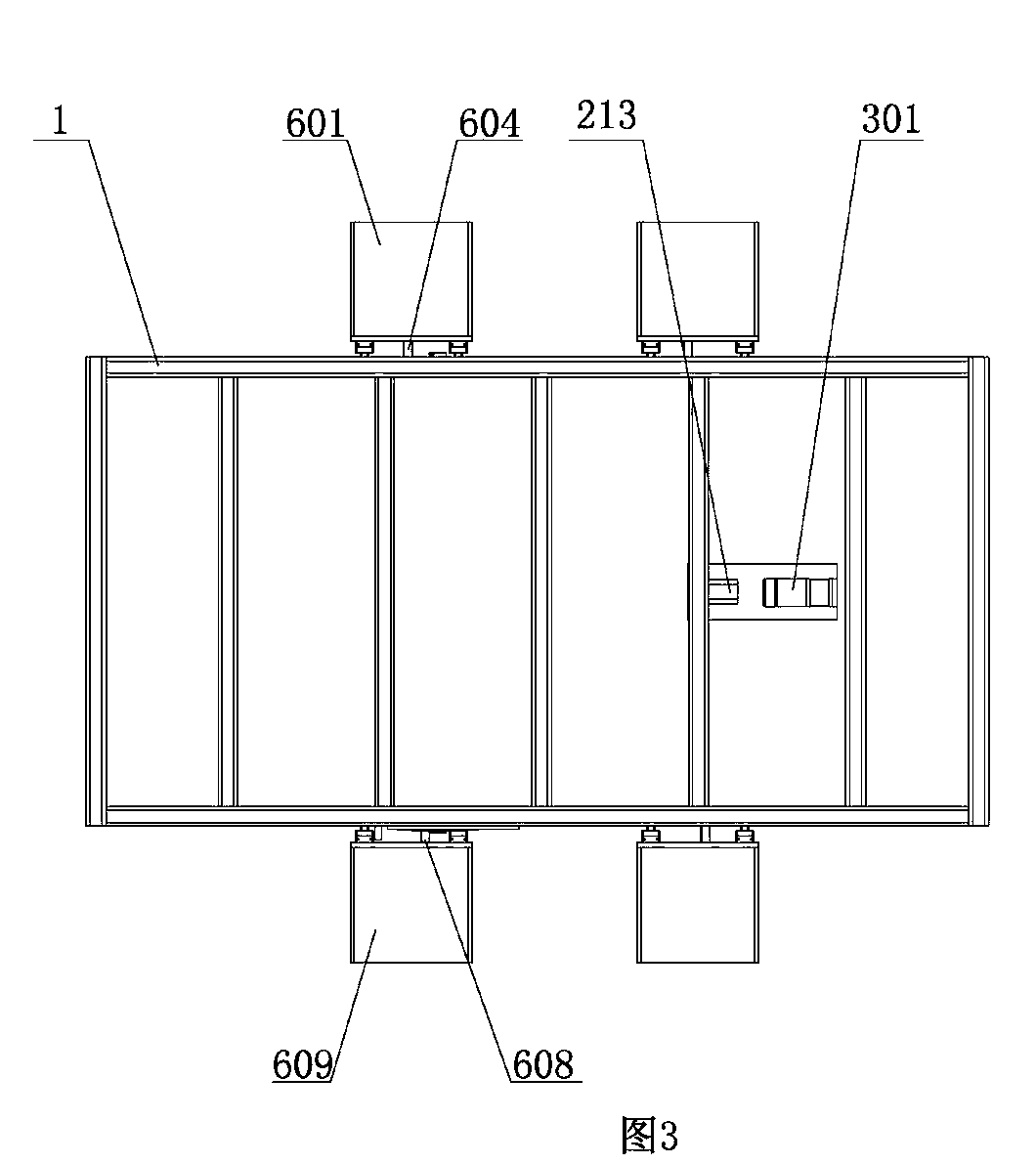

[0009] The tire protective cover hemming machine of the present invention comprises frame 1, as figure 2 and Figure 6 As shown, the edge turning mechanism is installed on the frame 1. A sliding fixed block 209 is installed on the executive part of the edge turning mechanism. A rotating shaft 205 and a swing arm driving motor 208 are installed on the sliding fixed block 209 . The output shaft of the swing arm driving motor 208 is connected with the rotating shaft 205 . A hemming mechanism is installed on the rotating shaft 205 . The hemming mechanism has a swing arm, and the inner pressure wheel 201 and the hemming ring gear 222 are installed on the swing arm. Drive motor 215 is installed on the moving seat, and rotating gear 218 is installed on the output shaft of driving motor 215, and rotating gear 218 meshes with the hemming ring gear 222, and the hemming driver is installed on the moving seat, and an external pressure wheel is installed on the output shaft of the hem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com