Preparation method for catalyst for hydrogen production by hydrocarbon reforming

A hydrocarbon conversion and catalyst technology, applied in the chemical industry, can solve the problem that the active metal is not a rod-shaped particle structure, and achieve the effects of high anti-coking ability, increased activity, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

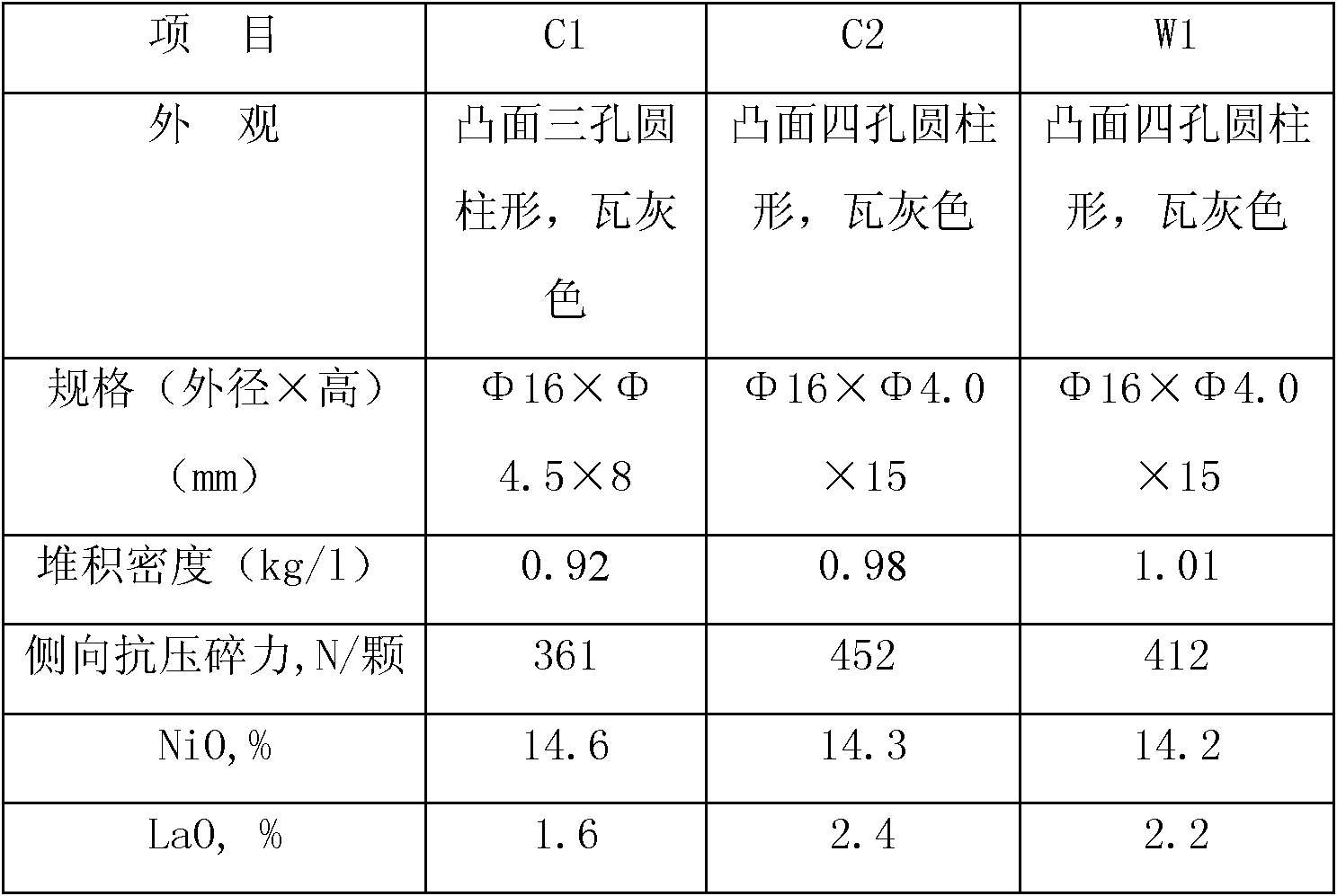

Embodiment 1

[0040] Take 320g of α-alumina, and then add 480g of pure calcium aluminate cement, 3.2g of ZrO 2, 4g kapok and 32g graphite to form a mixed material. Add 21g of deionized water, stir evenly, pre-press 4 times with a briquette machine, and the ball forming rate reaches 90%. Put it into a drying oven, dry at 120°C for 6 hours, pass through an 8-mesh sieve to granulate, and air-dry for 8 hours. Tablet molding is performed on a tablet press, with a specification of 16×15mm (four holes, inner hole Φ4.0mm). When the initial compressive strength is 30N / particle, steam curing is carried out for 36 hours, and the carrier is activated at 1150°C for 6 hours. Get the S1 vector.

[0041] A certain amount of La(NO 3 ) 2 , deionized water, prepared into a solution with a concentration of 0.4mol / l. Put the activated carrier into the step impregnation solution for equal volume impregnation. The catalyst was dried at 100°C for 10 hours. After drying, the catalyst was calcined at 900° C....

Embodiment 2

[0043] Take 380g of α-alumina, and then add 420g of pure calcium aluminate cement, 30g of ZrO 2 , 2g kapok and 25g graphite to form a mixed material. Add 270g of deionized water, stir evenly, pre-press 5 times with a briquette machine, and the ball forming rate reaches 80%. Put it into a drying oven, dry at 150°C for 6 hours, pass through an 8-mesh sieve to granulate, and air-dry for 10 hours. Tablet molding is performed on a tablet press, with a specification of 16×15mm (four holes, inner hole Φ4.0mm). When the initial compressive strength is 50N / particle, steam curing is carried out for 24 hours, and the carrier is activated at 1100°C for 8 hours. Get the S2 vector.

[0044] A certain amount of La(NO 3 ) 2 , deionized water, prepared into a solution with a concentration of 0.2mol / l. Put the activated carrier into the step impregnation solution for equal volume impregnation. The catalyst was dried at 130°C for 1 hour. After drying, the catalyst was calcined at 800° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com