Utility boiler pressure-bearing pipe leakage location method based on plane octave array

A power station boiler, a technology of positioning method, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of costing a lot of manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

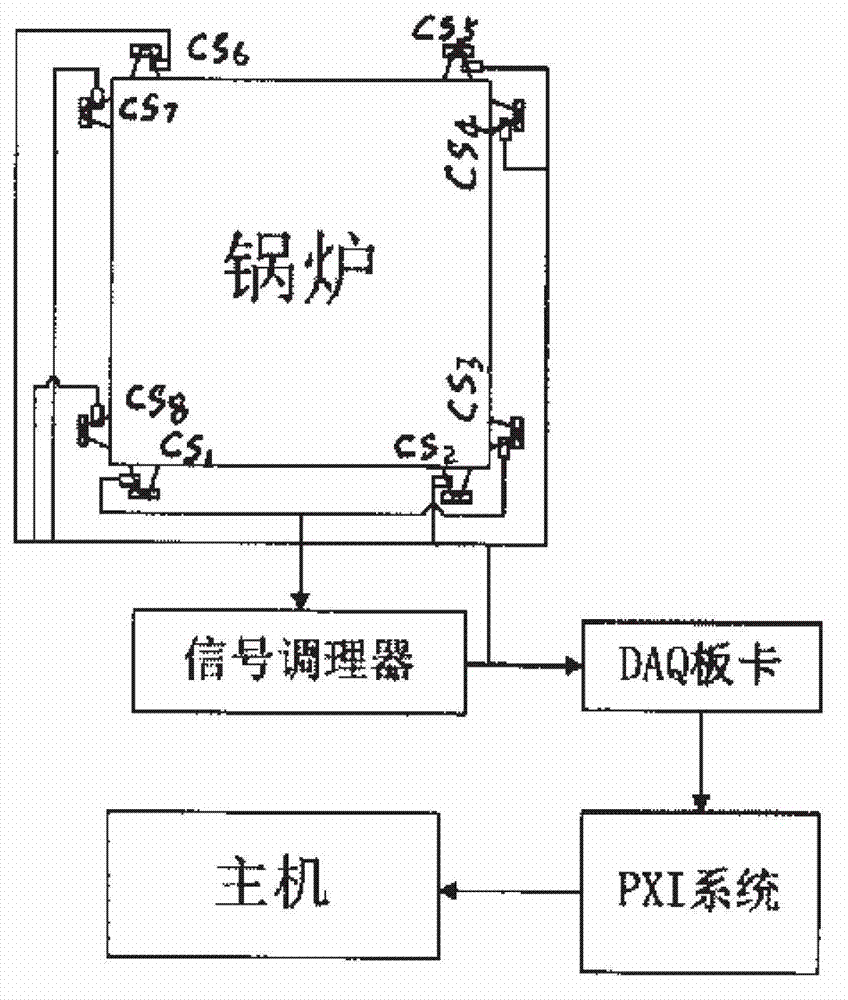

[0072] The present invention uses a plane eight-element array to accurately locate the leakage of the pressure-bearing tube of the power station boiler. The array structure of the microphone and its distribution in the furnace are as follows: figure 1 As shown, the arrangement of measuring points can be appropriately changed according to the site conditions. figure 2 Diagram of the precise location system for boiler pressure tube leakage. Combination of microphone and preamplifier (cs 1…… cs 8. ), using 1 / 2-inch pre-polarized electret measurement microphone MP201 (sensitivity 50Mv / Pa) and ICP preamplifier MA201. The output of the preamplifier is connected in series with the signal conditioner, DAQ board, PXI system and host; the positioning system is powered by 18V DC power supply; the preamplifier is used for the ICCP power supply of the microphone, and can filter and amplify the signal. There are three adjustment gears: 1x, 10x, and 100x, which are connected to the signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com