Lever arm detection platform

A detection platform, lever arm technology, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of time-consuming and cumbersome, and achieve the effect of accurate dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

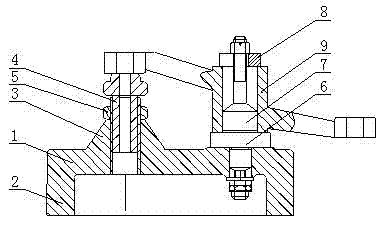

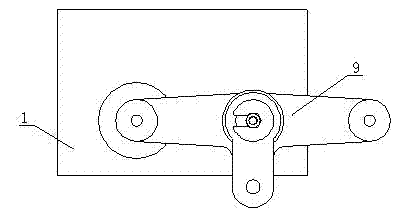

[0011] Such as Figure 1-3 As shown, the lever arm detection platform described in the embodiment of the present invention, the lever arm detection platform, includes a platform base 1, the platform base 1 is rectangular and is provided with four support feet 2 at the bottom, the platform base The upper surface of 1 is a plane, and a supporting round table 3 is provided on one side of the upper surface of the platform base 1. The center of the supporting round table 3 has a threaded hole, and a support member 4 is installed in the threaded hole 3. A lock nut 5 is installed on the lower part of the piece 4, and a positioning boss 6 docked with the lever arm 9 is provided on the other side of the upper surface of the platform base 1, and a lever arm 6 is installed at the center of the positioning boss 6. The positioning pin 7 docked with the center hole of the arm 9 is provided with a compression nut 8 on the top of the positioning pin 7, and the distance between the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com