Headlamp reflector and motor vehicle headlamp

A technology of headlights and reflectors, which is applied in the field of lighting, can solve the problems of increasing production and maintenance costs, the lack of versatility of headlights, and the inability to make uniform positions, and achieve the effect of saving costs and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

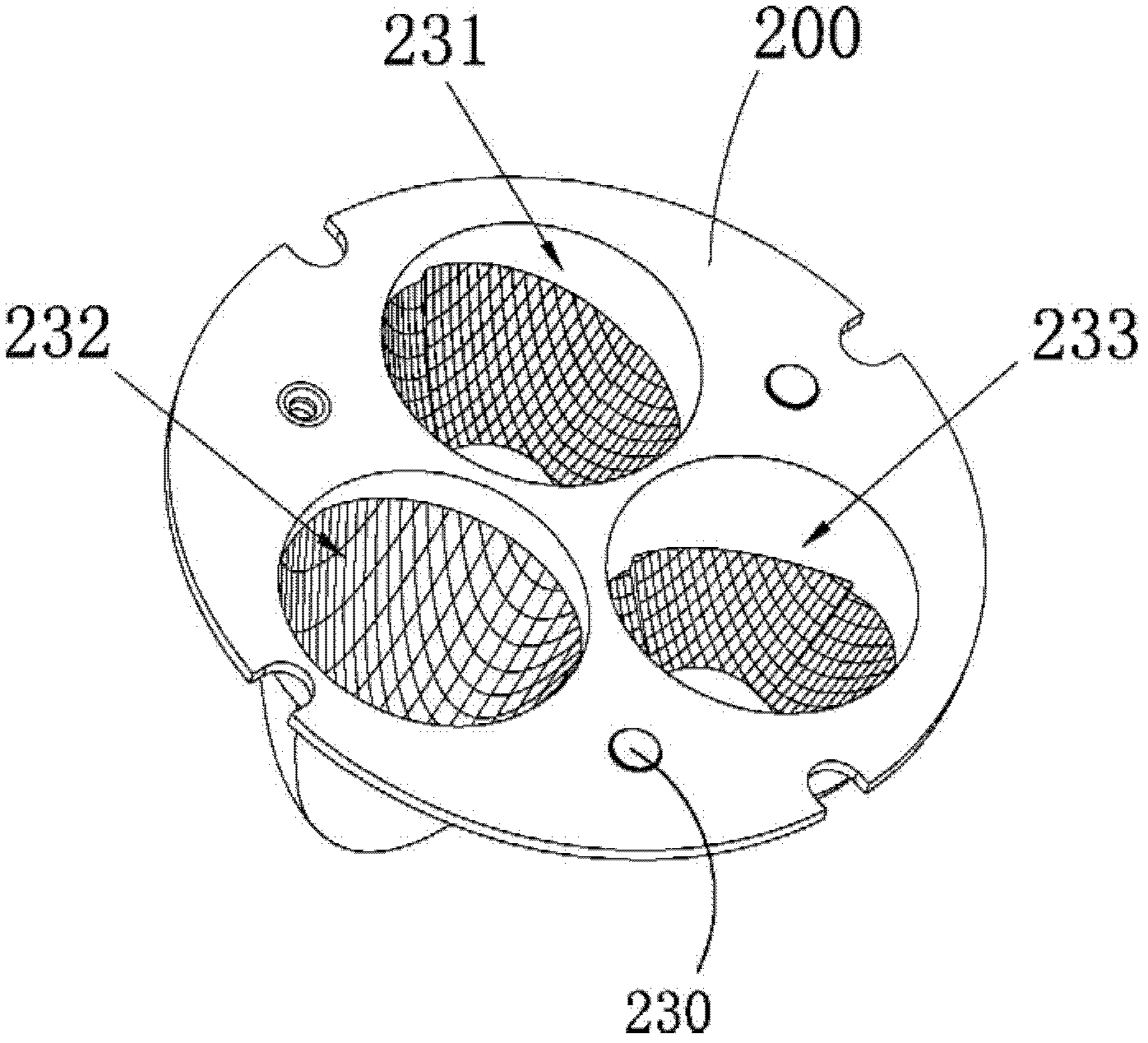

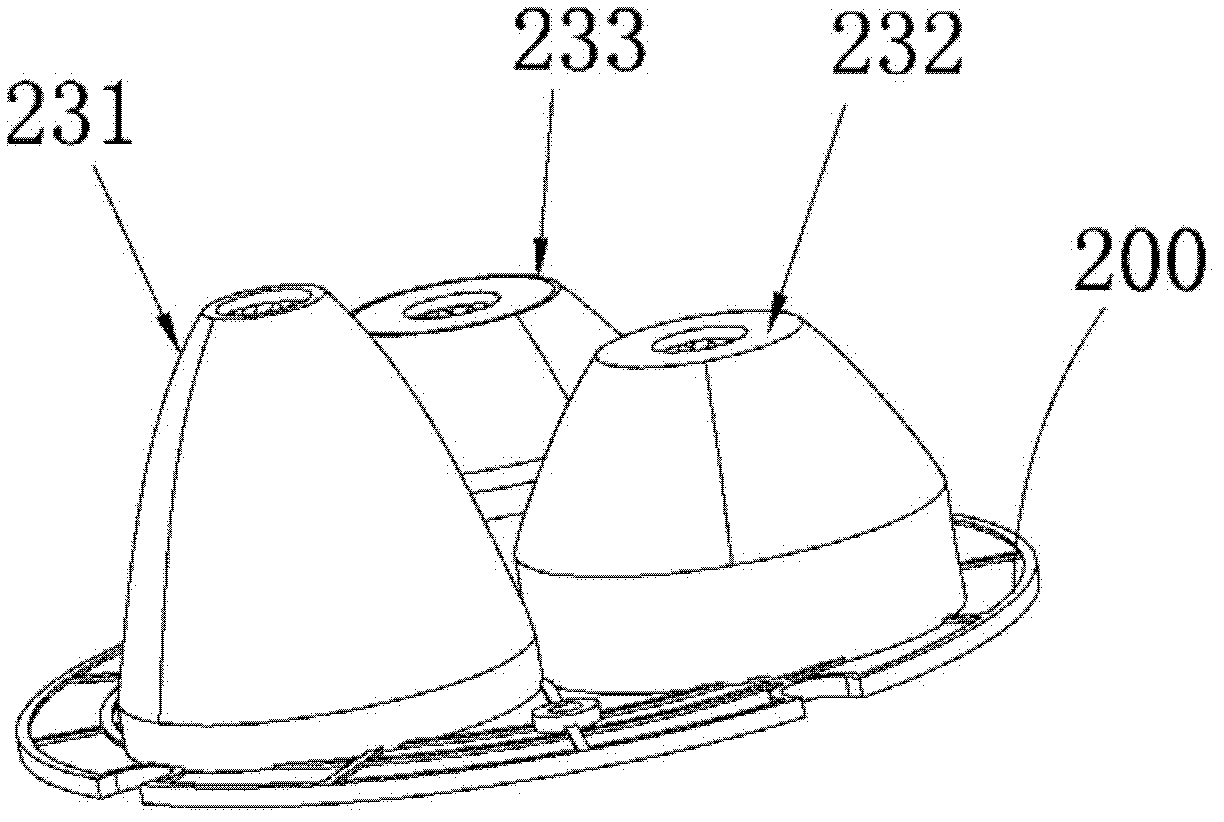

[0035] Further, see Figure 4 and Figure 5 , as a preferred embodiment of the motor vehicle headlight provided by the present invention, the fixing holes on the heat sink 21 are set to four, which are the first fixing hole 211, the second fixing hole 212, and the third fixing hole 213. and the fourth fixing hole 214, and are uniformly distributed at intervals of 90° on the circumference; the connecting holes on the lamp housing 1 are set to two, which are the first connecting hole 11 and the second connecting hole 12, and are arranged on the circumference 180° interval distribution. In this embodiment, the optical assembly 2 is mounted on the lamp housing 1 through the first fixing hole 211 and the third fixing hole 213 in cooperation with the first connection hole 11 and the second connection hole 12, or, The optical assembly 2 is mounted on the lamp housing 1 through the second fixing hole 212 and the fourth fixing hole 214 in cooperation with the first connecting hole 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com