Oiling device for spring part of clock

An oiling device and clock spring technology, which is applied to engine components, engine lubrication, mechanical equipment, etc., can solve problems such as uneven coating surface, low work efficiency, and short life, so as to achieve uniform oiling surface and improve efficiency , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

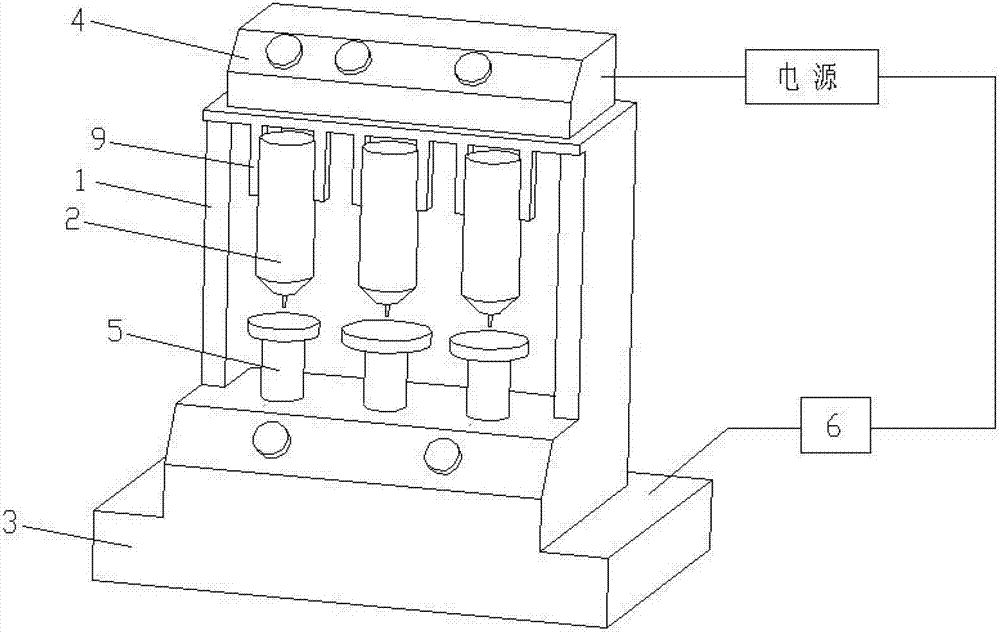

[0022] Please also refer to Figure 1 to Figure 3 , as shown in the figure, the oiling device for clock spring parts includes a base 3, a housing 1 arranged on the base 3, a spraying assembly installed on the housing 1, and the spraying assembly further includes an oiling pipe 2 and a The fixing frame 9 for fixing the oiling pipe 2; also includes the air pressure regulator 4 arranged above the casing 1 and providing pressure to the inside of the oiling pipe 2, the driving mechanism installed on the base 3, and the synchronous servo motor 6 that drives the driving mechanism to work , the turntable 5 driven by the driving mechanism, the turntable 5 is arranged directly below the oiling pipe 2, and the synchronous servo motor 6 and the air pressure regulator 4 are connected to the power supply. The driving mechanism also includes a rotating rod 7 with one end arranged at the bottom of the turntable 5 and the other end connected to the base 3 , and a gear 8 sleeved on the rotating...

Embodiment 2

[0024] see Figure 4 , on the basis of Embodiment 1, at least two groups of spraying assemblies are arranged on the oiling device, and three groups of spraying assemblies are shown in the figure, and a corresponding turntable 5 is arranged directly below the oiling pipe 2 of each group of spraying assemblies, Moreover, in order to prevent the oil mist sprayed by each group of spraying components from interfering, a baffle plate 10 is arranged between each group of spraying components, and the baffle plate 10 is fixedly arranged on the housing 1 .

[0025] A working air pressure is pre-set inside the oiling pipe 2 through the air pressure regulator 4. Driven by the synchronous servo motor 6, the turntable 5 rotates one revolution, and the clock spring component rotates synchronously on the turntable 5. When the parts rotate, the oiling pipe 2 The grease inside is injected under the pressure of the air pressure and coated on the surface of the parts, and the oiling is also compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com