Sound insulation module and sound absorption and insulation composite structure of embedded truss structure with sound insulation module

A composite structure and truss structure technology, applied in the direction of sound insulation, building components, building structure, etc., can solve the problems of the decline of the sound insulation performance of the wall, secondary pollution, and many processes, so as to improve the sound insulation performance and save the production cost. , the effect of low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

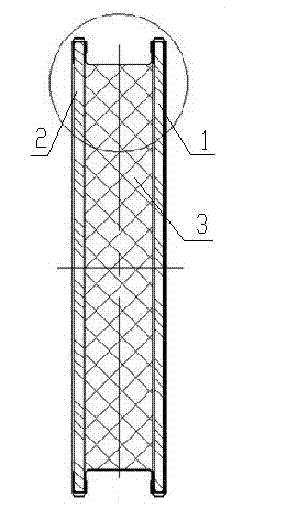

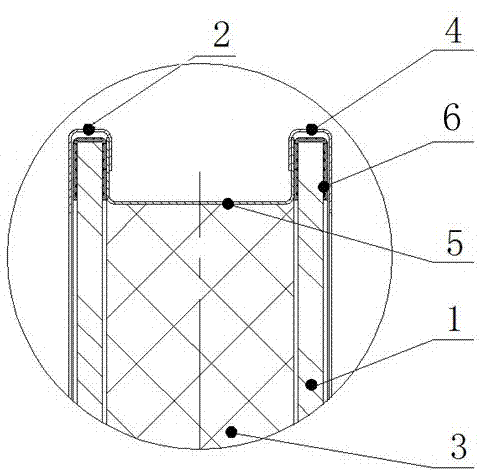

Embodiment 1

[0030] Embodiment 1: as Figure 1 to Figure 3 As shown, a sound insulation module includes a first sound insulation board 1, a second sound insulation board 2 and a sound absorbing body 3 between the two sound insulation boards, the first sound insulation board 1 and the second sound insulation board The ends of the board 2 are covered by the groove bar 4, and the groove bar 4 overlaps and fixes the U-shaped enclosure 5 between the ends of the first sound insulation board 1 and the second sound insulation board 2, so that the whole A groove is formed at the end of the sound insulation module; the first sound insulation board 1 and the second sound insulation board 2 are wrapped with U-shaped elastic rubber bead 6; the thickness of the sound absorber 3 is 50-300 mm.

Embodiment 2

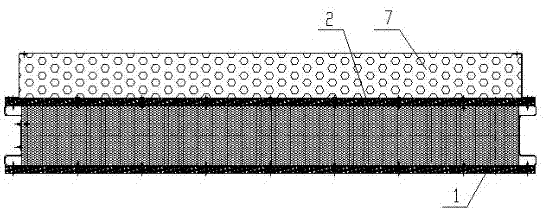

[0031] Embodiment 2 is different from Embodiment 1 in that the sound insulation module has a built-in sound insulation material wrapped in non-alkali glass fiber cloth on the outer layer of the first sound insulation board 1, and the outer layer of the second sound insulation board 2 is attached and connected with perforations The board 7 is filled with sound-absorbing material between the two sound-insulating boards, that is, it is combined into a structure of sound-insulating material-sound-absorbing material-perforated board 7, the thickness of the perforated board 7 is 1-12 mm, and the perforation rate is 23%-65% The sound-absorbing material is glass wool or melamine, and the perforated plate 7 is steel plate, aluminum plate, cement fiberboard or gypsum board, and its thickness is 5-30mm. Other structures are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0032] Example 3, such as Figure 4 and Figure 5 As shown, the sound-absorbing and insulating composite structure with the embedded truss structure of the sound insulation module described in Embodiment 2 includes a truss column 9 embedded in the factory building column 8 and can be fixed to the ground, and between the bottom of the truss column 9 The well-shaped truss structure formed by the embedded bottom beam and the horizontal support truss 11 fixedly connected with the truss column 9, the groove of the sound insulation module is nested on the truss column 9 and is located between the embedded bottom beam and the horizontal Between the supporting trusses 11; the sound absorbing body 3 is fixed on the first sound insulation board 1 or the second sound insulation board 2 of the sound insulation module by screws; the outer side of the well-shaped truss structure is installed with a corrugated board armor 10; The truss column 9 is H-shaped steel with a thickness of 45-295 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com