Vertical double-sided milling machine

A double-sided, milling machine technology, applied in milling machine equipment, milling machine equipment details, clamping and other directions, can solve problems such as inability to meet mass production needs, inability to guarantee machining accuracy, time-consuming, labor-intensive, etc., to improve machining accuracy and machining. The effect of high efficiency, high work efficiency and high workpiece accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

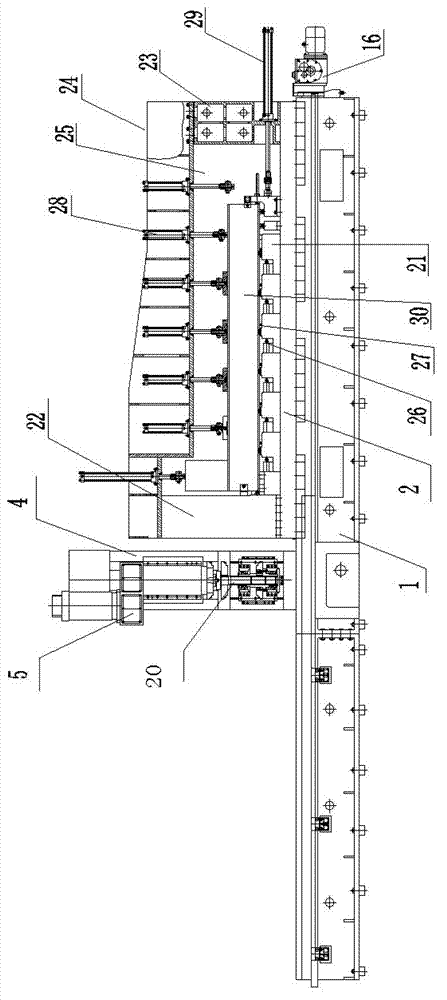

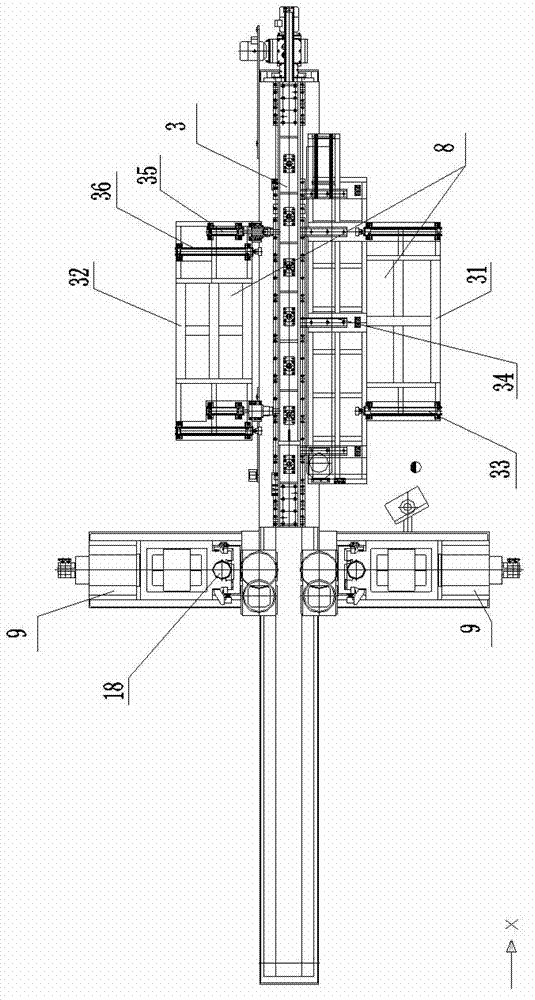

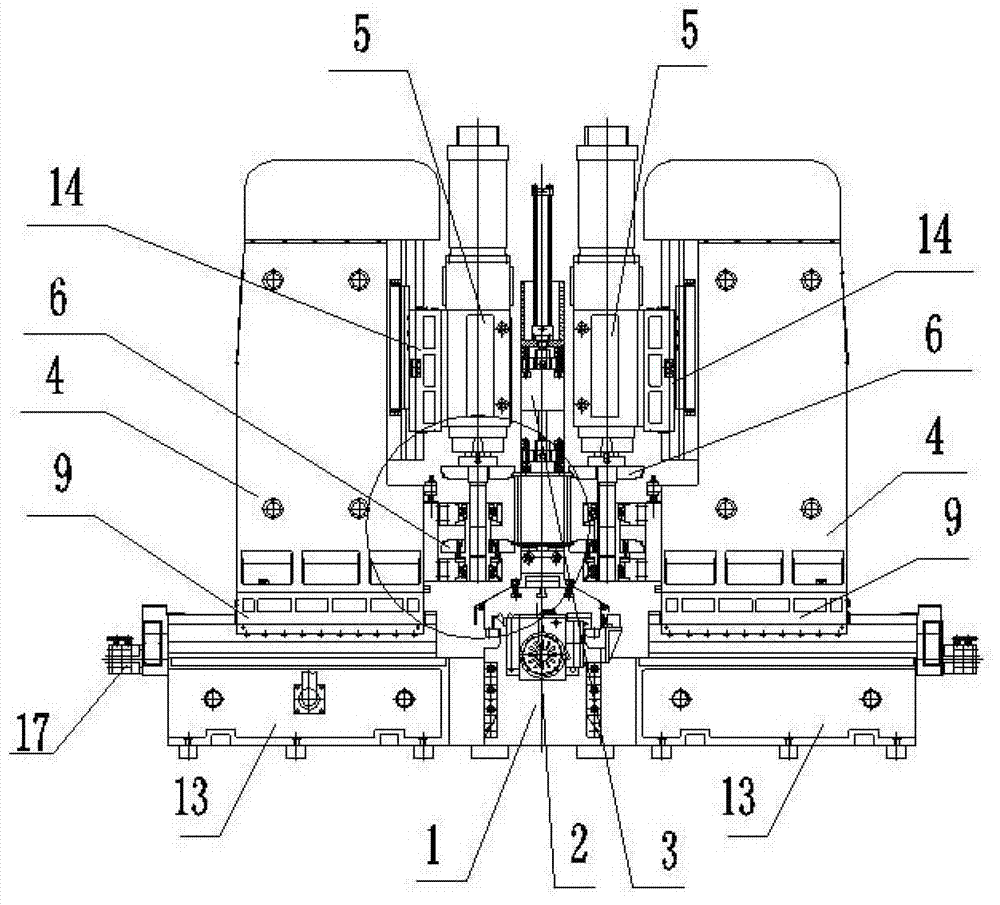

[0014] Attached below figure 1 -5 describes an embodiment of the present invention.

[0015] A vertical double-sided milling machine, which has a middle base 1 and two side bases 13 symmetrically arranged on both sides of the middle base 1, the middle slide 2 is installed on the middle base 1, and the middle slide 2 is provided with Clamping device 3, described side base 13 is all equipped with side slide table 9, is all fixed with column 4 on described side slide table 9, and column slide table 14 is all installed on the front end top of described column 4, and described column The spline sleeve shaft 19 is installed vertically under the front end of 4, and the cutterhead I 15 is fixed on the spline sleeve shaft 19; the power head 5 is installed on the column slide table 14, and the power head 5 at the lower end of the power head 5 The cutterhead II6 is installed on the output shaft 7; the cutterhead I15 is located directly below the cutterhead II6, the power output shaft 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com