Cleaning machine for glass substrates

A technology for glass substrates and washing machines, which is applied in the direction of dryers, conveyor objects, cleaning flexible objects, etc., can solve the problems of aggravating the vibration of the glass substrate 20, breakage of the glass substrate 20, and easy floating, so as to improve the yield rate and Yield, good cleaning, avoid breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

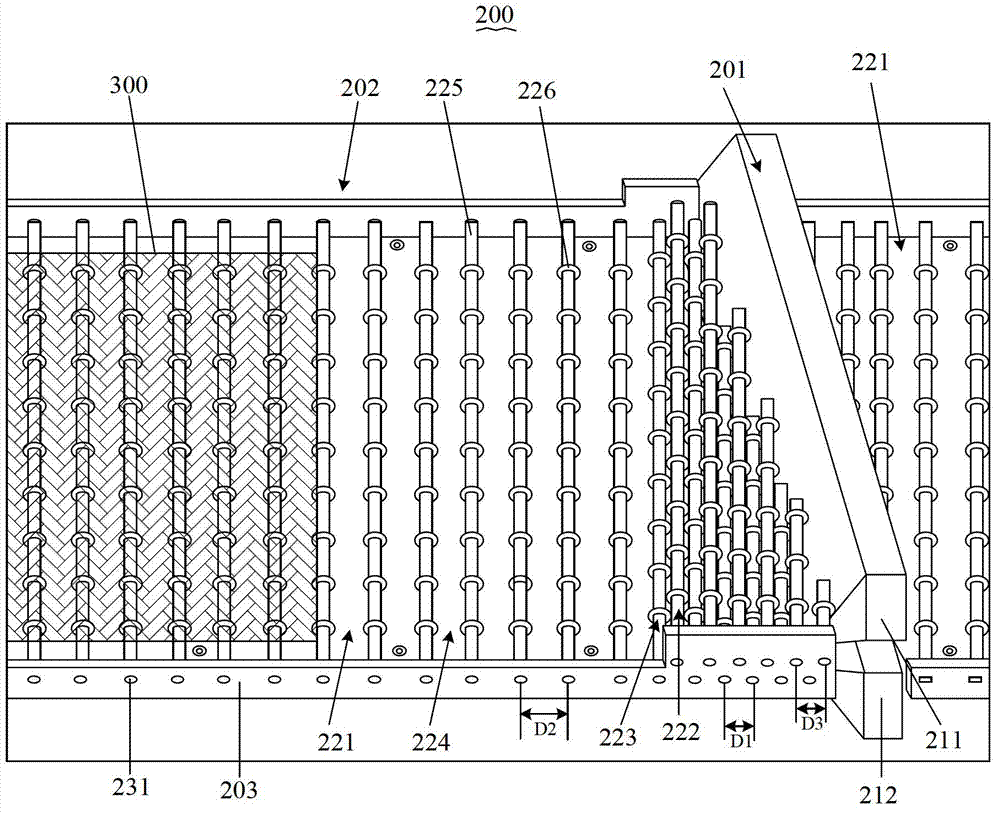

[0019] see figure 2 , figure 2 It is a structural schematic diagram of an embodiment of the glass substrate cleaning machine of the present invention, as figure 2 As shown, the glass substrate cleaning machine 200 of the present invention includes an air knife 201 and a conveying device 202 .

[0020] Wherein, the air knife 201 is driven by compressed air to form a thin, high-strength, high-flow impingement air curtain for drying the glass substrate 300 .

[0021] In this embodiment, the air knife 201 is preferably made of aluminum alloy or stainless steel.

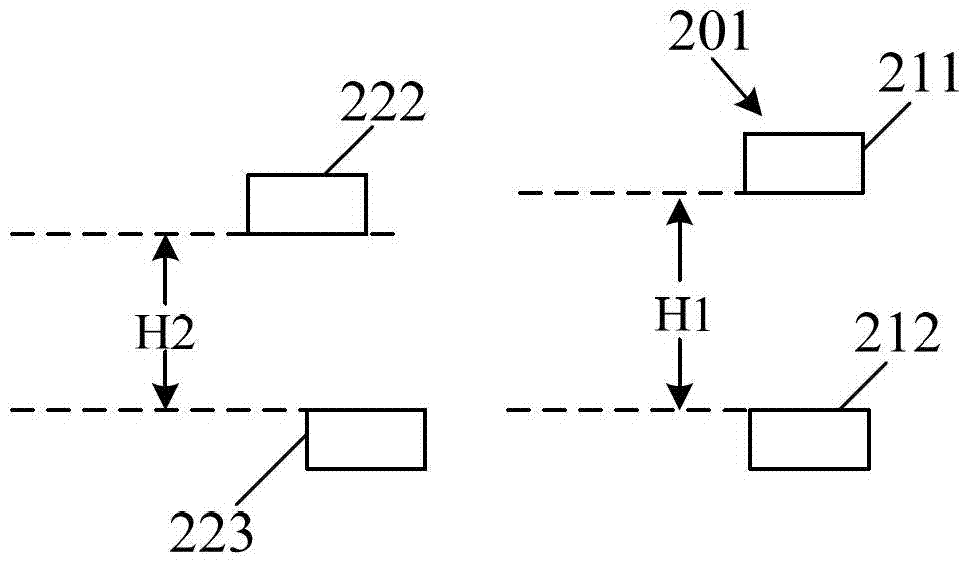

[0022] The conveying device 202 includes a main conveying roller set 221 and an auxiliary conveying roller set 222 respectively disposed on the upper and lower sides of the glass substrate 300 . Wherein, the main conveying roller set 221 is used to carry and convey the glass substrate 300 , which are respectively arranged on the front and rear sides of the air knife 201 and located below the glass substrate 300 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com