Automatic compression roller gap regulation meshing type extruding and crushing machine

An automatic adjustment and crusher technology, applied in grain processing and other directions, can solve the problems that the equipment cannot achieve medium crushing, fine crushing and grinding in one machine, large investment cost and maintenance workload, and many supporting systems, etc., and achieves a simple structure. , Save investment cost, solve the huge effect of crushing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

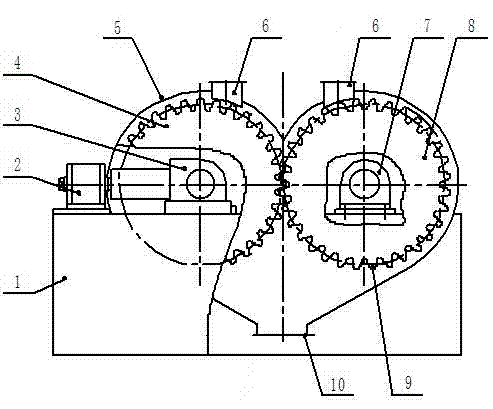

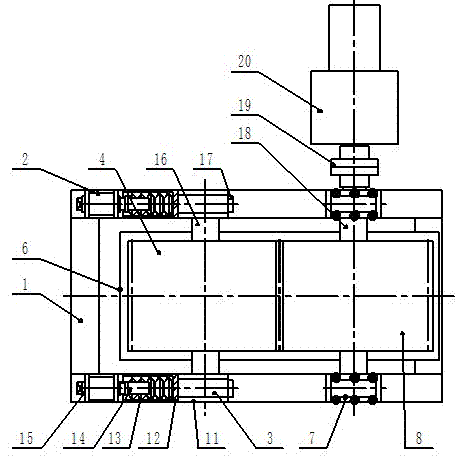

[0023] Such as figure 1 and figure 2 As shown in the figure, a meshing squeeze crusher that can automatically adjust the gap between the rollers includes a fixed roller 8 driven by a power system, and a movable roller 4 that is meshed with the extrusion teeth 9 of the fixed roller 8. The gap between the pressing roller 4 and the fixed pressing roller 8 is regulated by an elastic adjusting device that can slide on the guide rail 11 of the frame 1 .

[0024] Described elastic adjusting device comprises the sliding bearing seat 3 that is connected with movable pressing roller 4 through movable pressing roller shaft 16 and can slide on frame 1 guide rail 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com