Printed circuit board laminating structure and laminating method

A technology for printed circuit boards and circuit boards, applied in the directions of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of difficult structural design and lack of competitive advantages, so as to reduce the difficulty of structural design, suitable for popularization and application, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

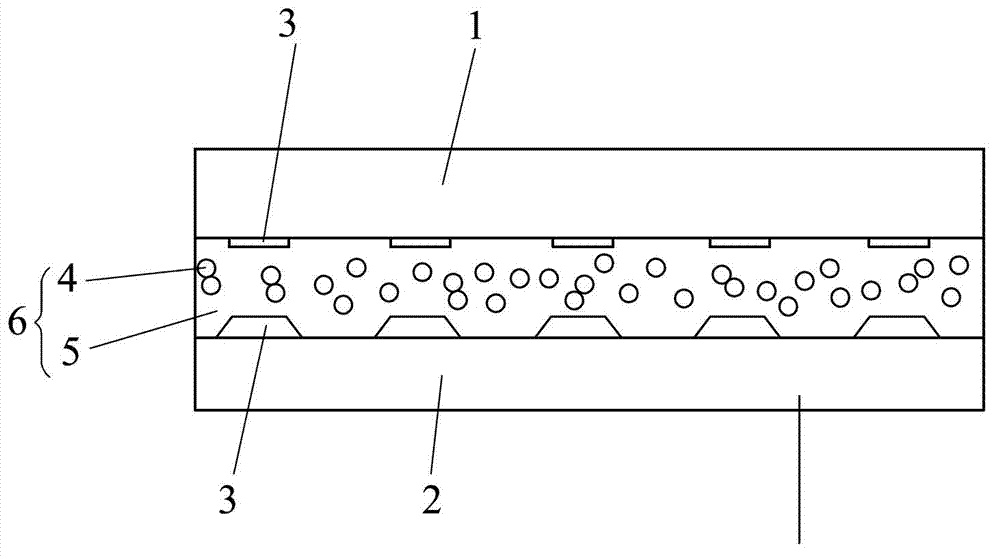

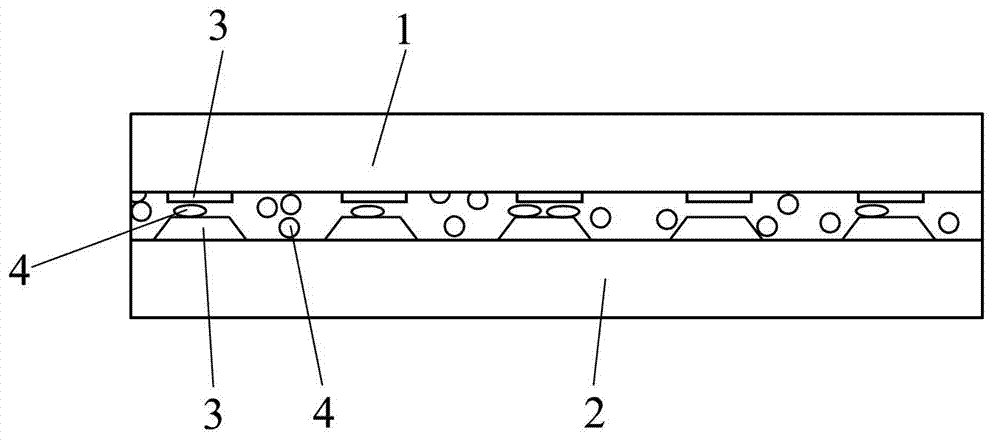

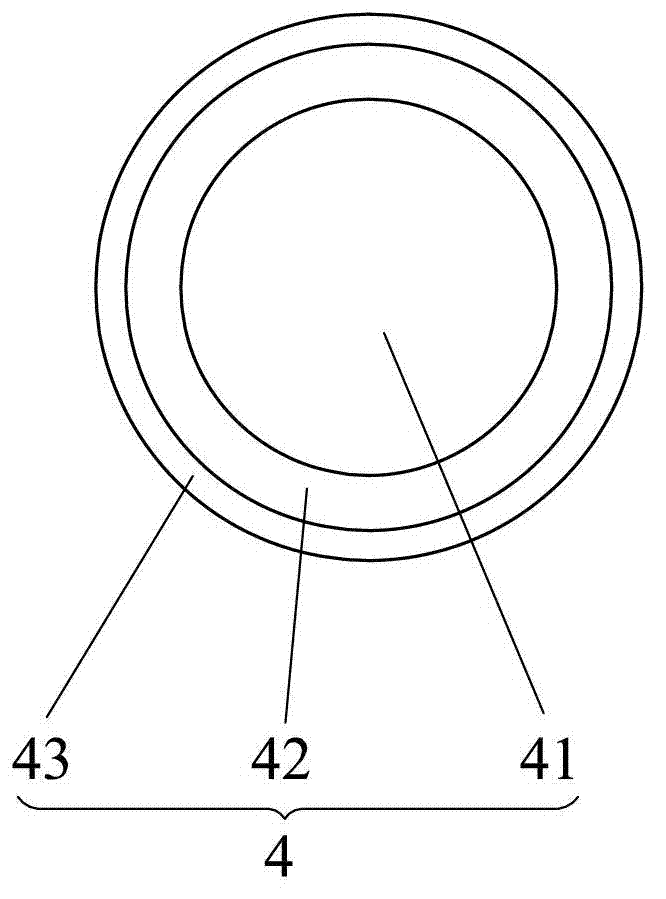

[0020] refer to figure 1 and figure 2 , a printed circuit board pressing structure, including two circuit boards 1 and 2, the two circuit boards are discontinuously provided with opposite golden fingers 3, conductive particles 4 and resin adhesive are distributed between the two circuit boards The conductive adhesive 6 composed of 5, by pressurizing and heating the circuit boards, the conductive particles 4 are broken at the opposite positions of the gold fingers 3 on the two circuit boards, and squeezed together to form conduction without the position of the gold fingers The conductive particles 4 are not broken and conduction is not formed.

[0021] The conductive adhesive is anisotropic conductive adhesive, referred to as ACF adhesive, and its full name is Anisotropic Conductive Film. It is a translucent polymer continuous material with three characteristics of adhesion, conductivity, and insulation. It conducts electricity in the Z direction, and X, Y directions Non-con...

Embodiment 2

[0028] refer to figure 1 and figure 2 , a printed circuit board pressing structure, including two circuit boards 1 and 2, the two circuit boards are discontinuously provided with opposite golden fingers 3, conductive particles 4 and resin adhesive are distributed between the two circuit boards The conductive adhesive 6 composed of 5, by pressurizing and heating the circuit boards, the conductive particles 4 are broken at the opposite positions of the gold fingers 3 on the two circuit boards, and squeezed together to form conduction without the position of the gold fingers The conductive particles 4 are not broken and conduction is not formed.

[0029] The conductive adhesive is anisotropic conductive adhesive, referred to as ACF adhesive, and its full name is Anisotropic Conductive Film. It is a translucent polymer continuous material with three characteristics of adhesion, conductivity, and insulation. It conducts electricity in the Z direction, and X, Y directions Non-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com