Half-module pivoted window mechanism applied to sub transonic speed wind tunnel

A wind tunnel and mold turning technology, applied in the field of half mold turning window mechanism, can solve problems such as difficulty in realizing circular rotation, inability to realize overall hoisting, inconvenient installation and disassembly, etc., so as to improve accuracy, reduce test preparation time, and process cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

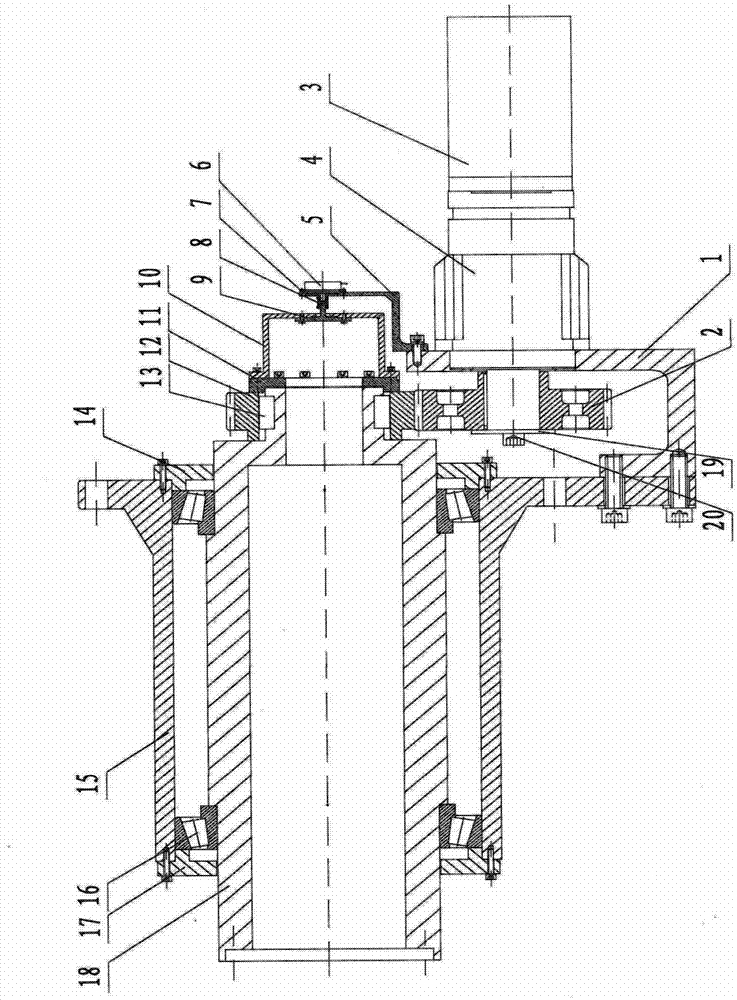

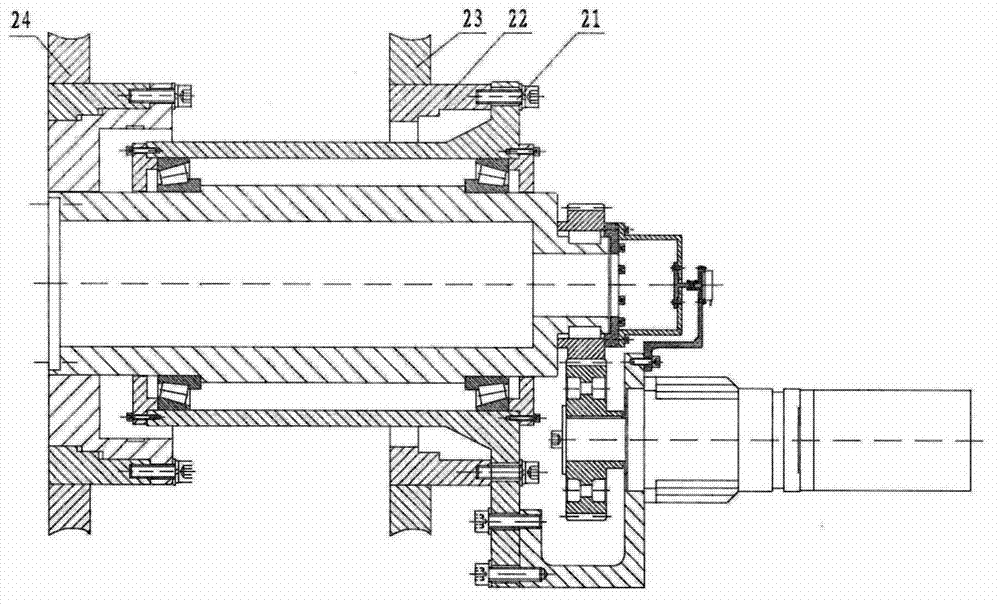

[0025] The invention provides a half-mode window turning mechanism applied to a sub-transonic wind tunnel, such as figure 1 As shown, it includes: support 1, large cylindrical spur gear 2, AC servo motor 3, reducer 4, potentiometer support 5, potentiometer 6, pressing plate 7, coupling 8, small shaft 9, connecting cover 10 , gear gland 11, small cylindrical spur gear 12, key 13, right bearing cover 14, bearing housing 15, tapered roller bearing 16, left bearing cover 17, main shaft 18, compression cover 19 and compression screw 20;

[0026] The invention can be divided into three modules: a drive transmission module, a feedback and measurement module and a rotation module. Among them, the support 1, the large cylindrical spur gear 2, the AC servo motor 3, the reducer 4, the gear gland 11, the small cylindrical spur gear 12, the compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com