CO2 refracturing process technology for low-permeability gas well

A technology of repeated fracturing and process technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., and can solve problems such as incompleteness and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

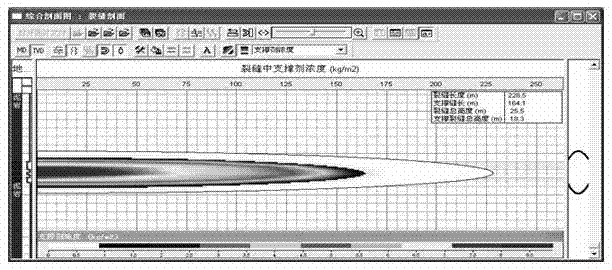

[0022] Take the refracturing of the 2nd member of XXX Jingshan as an example.

[0023] Low permeability gas well CO 2 Refracturing technology, which is a second fracturing operation for wells that have been put into production. It includes two parts: pre-fracturing analysis and optimization and fracturing construction. Pre-fracturing analysis and optimization includes fracturing failure analysis and fracturing material selection. and optimization of construction parameters.

[0024] Low permeability gas well CO 2 Refracturing technology is implemented in the following steps:

[0025] Step 1. Perform a fracturing failure analysis on the well to be constructed to determine whether there is a possibility of refracturing. The analysis results show that the 2nd section of XXX Jingshan can be refractured.

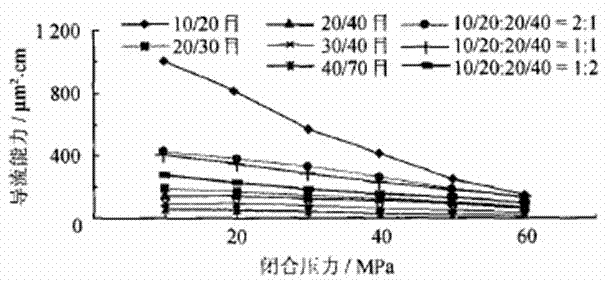

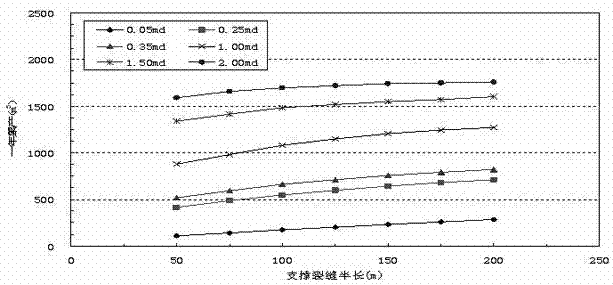

[0026] Step 2, selection of fracturing materials, is divided into selection of fracturing fluid and proppant.

[0027] (1) Selection of fracturing fluid:

[0028] CO 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com