Method and device for performing on-line profile control on polymer driving oil field by applying crosslinking agent

A technology of cross-linking agent and polymer, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and mining, etc. It can solve problems such as viscosity reduction, complex composition, and large construction displacement, so as to prevent viscosity reduction, Good operation controllability and good profile control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

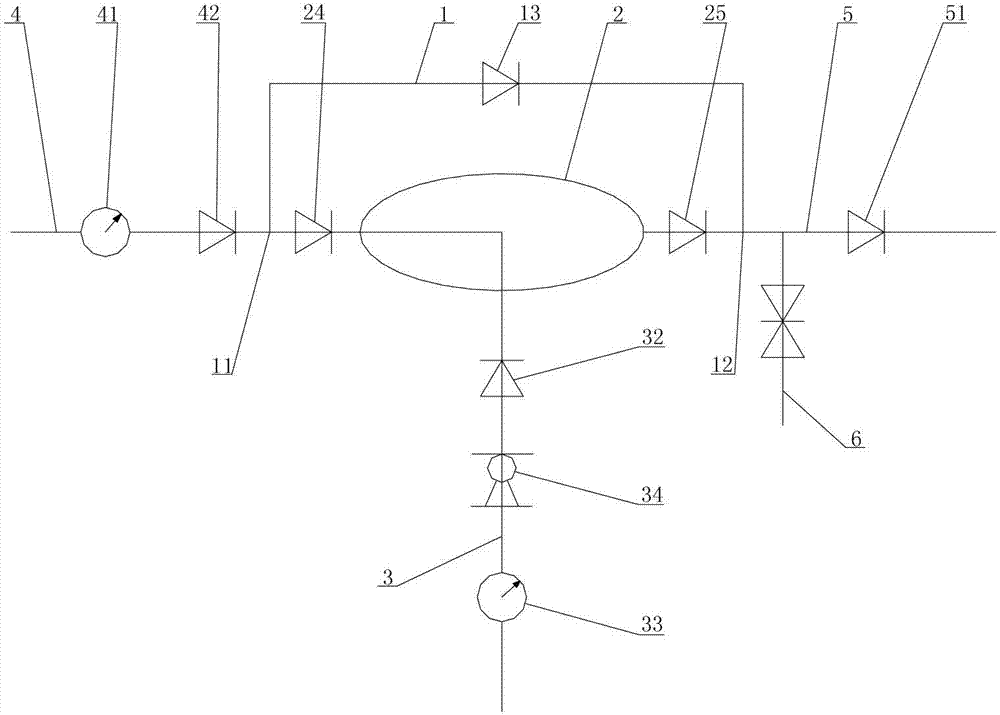

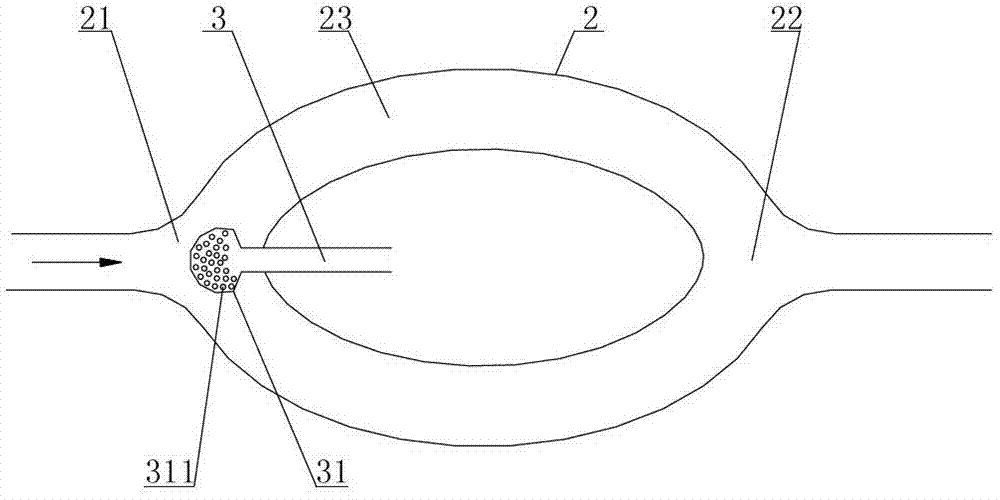

[0034] see figure 1 , figure 2 As shown, the present invention provides an online profile control device for polymer flooding oil field, which includes a polymer solution injection pipeline 1 , an annular liquid mixer 2 and a crosslinking agent solution inlet pipeline 3 . Wherein: the polymer solution injection pipeline 1 has an inlet port 11 and an outlet port 12; the annular liquid mixer 2 is arranged in parallel with the polymer solution injection pipeline 1, and the annular liquid mixer 2 is provided with an annular cavity 23 that is generally an ellipse ring, The two ends of the long axis are respectively provided with a liquid inlet bell mouth 21 and a liquid outlet bell mouth 22 (along the liquid inlet → liquid outlet direction, the liquid inlet bell mouth 21 gradually expands, and the liquid outlet bell mouth 22 gradually shrinks). The inlet end 11 of the polymer solution injection line 1 communicates with the liquid inlet bell mouth 12 of the annular liquid mixer 2,...

Embodiment 2

[0042] Using the device described in Example 1, a cross-linking agent is used for on-line profile control in a polymer flooding oil field. in:

[0043] Polymer solution: polyacrylamide solution with a concentration of 0.3%wt.

[0044] Crosslinking agent solution: formaldehyde 2.0%wt, ammonium chloride 0.5%wt, resorcinol 0.1%wt, balance water.

[0045] The specific operation is as follows:

[0046] 1. Open the one-way stop valves 42, 13, 51, and inject the polymer solution into the polymer solution inlet line 4. During the process of injecting the polymer solution, the annular liquid mixer 2 is in a closed state, and the The polymer solution flows into the mixed liquid outlet pipeline 5 through the polymer solution injection pipeline 1, and then injected into the water injection well; this process is a normal polymer flooding process;

[0047] 2. Open the one-way stop valves 24 and 25, and close the one-way stop valve 13;

[0048] 3. Read the value of the flowmeter 41, open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com