Sputtering machine and control method for magnet thereof

A control method and technology of a sputtering machine, which are applied in the directions of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems such as increased production cost and edge detachment of target materials, so as to avoid waste and solve production problems. effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] According to an embodiment of the present invention, a sputtering machine is disclosed. The sputtering machine is suitable for carrying a substrate. The sputtering machine is used to perform a sputtering process on the substrate, so as to separate a target and form the target on the substrate.

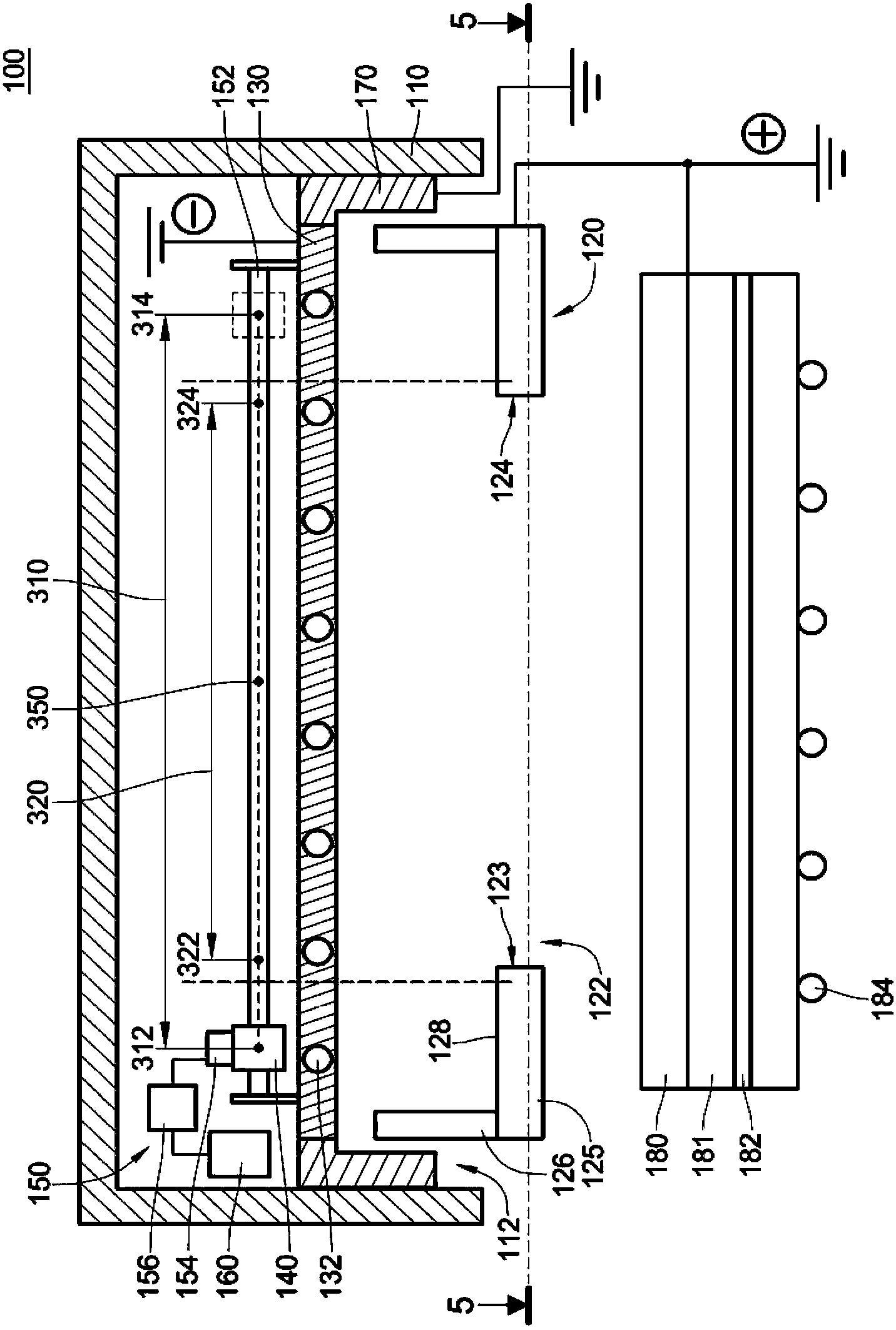

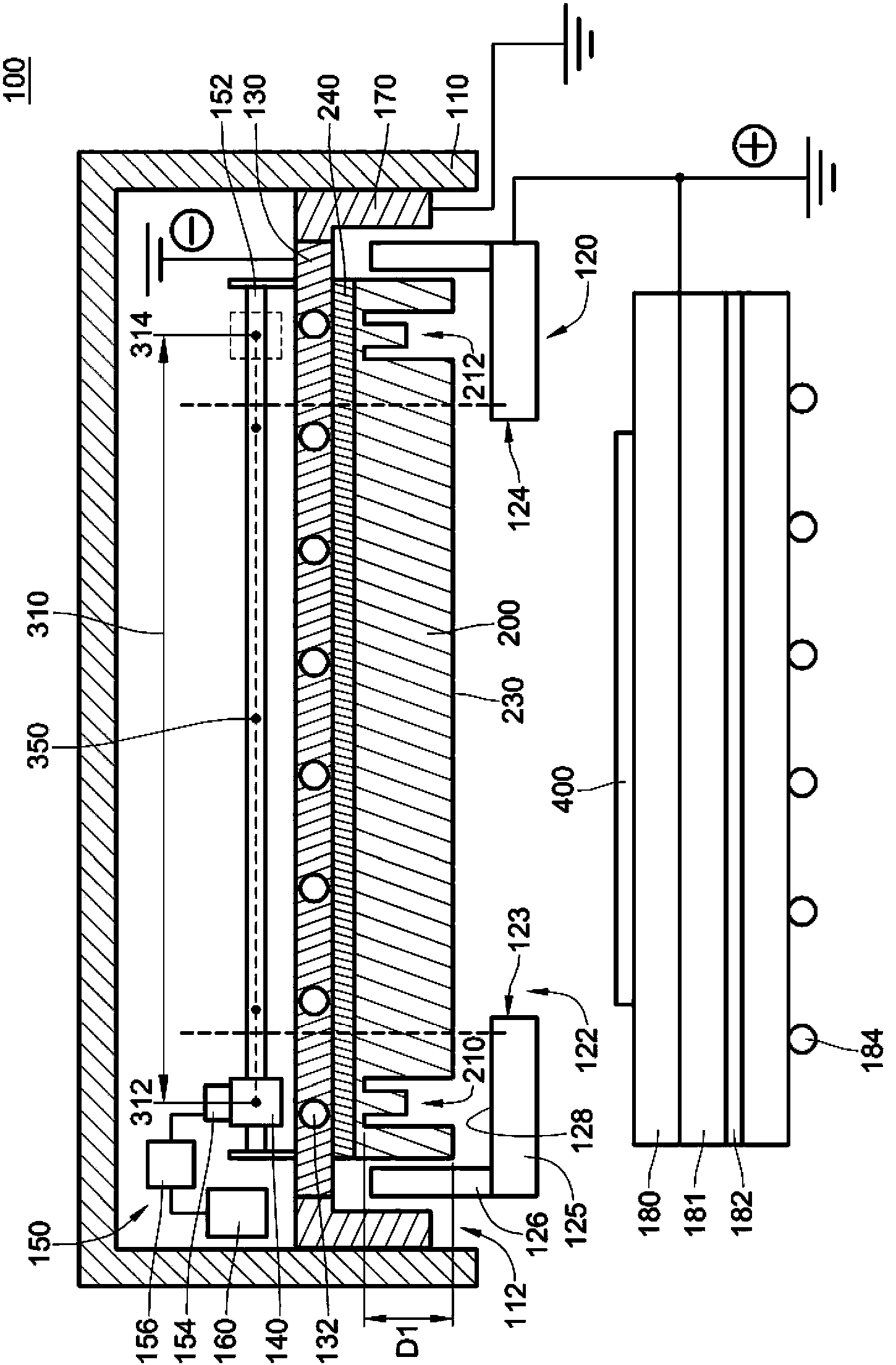

[0074] Please refer to figure 1 , figure 1 It is a schematic cross-sectional view of a sputtering machine according to an embodiment of the present invention. In this embodiment, the sputtering machine 100 includes a chamber 110 , a shield 120 , a target carrier 130 , a magnet 140 , a driving mechanism 150 and a programmable controller 160 .

[0075] The chamber 110 has a chamber opening 112 . The target carrier 130 is suitable for carrying a target (not shown). In addition, the target carrier 130 corresponds to the chamber opening 112 . For example, a cooling water channel 132 is provided in the target carrier 130 , and the cooling water channel 132 is used for cooling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com