Radar, video and laser system combined device for measuring blast furnace burden surface

A blast furnace material surface and laser system technology, applied in inspection devices and other directions, can solve the problems of increased material surface error, poor measurement effect, and many laser rangefinders, etc., to increase reliability and intuitiveness, save installation space, The effect of reducing the amount of construction

Active Publication Date: 2012-12-12

UNIV OF SCI & TECH BEIJING

View PDF10 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the data is not obtained by directly measuring the information of the material level, the error of the material level obtained by processing the data will increase. Another disadvantage is that the laser cannot be used in a dusty production environment, and it is often used when the furnace is turned on. Well, poor measurements in production

[0016] In the Chinese Patent Publication No. CN102312031A, the invention patent "Measuring Device and Method for Blast Furnace Roof Material Level Without Material Bell", it uses the existing mechanical probe in the blast furnace to install a laser rangefinder, gyroscope and wireless transmission on it. The device constitutes a material level measurement system. The existing problem is that the blast furnace system it measures is a bellless blast furnace, which has great limitations on the application premise; There are many instruments and the cost is high; finally, the measured data are only points on a line on the material surface (the number of measured real data is related to the number of lasers), and the number of installed laser rangefinders is limited. This will lead to very effective collection of data points. A large amount of data on the material surface is obtained by fitting, and the shape of the final material surface may be quite different from the real material surface.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

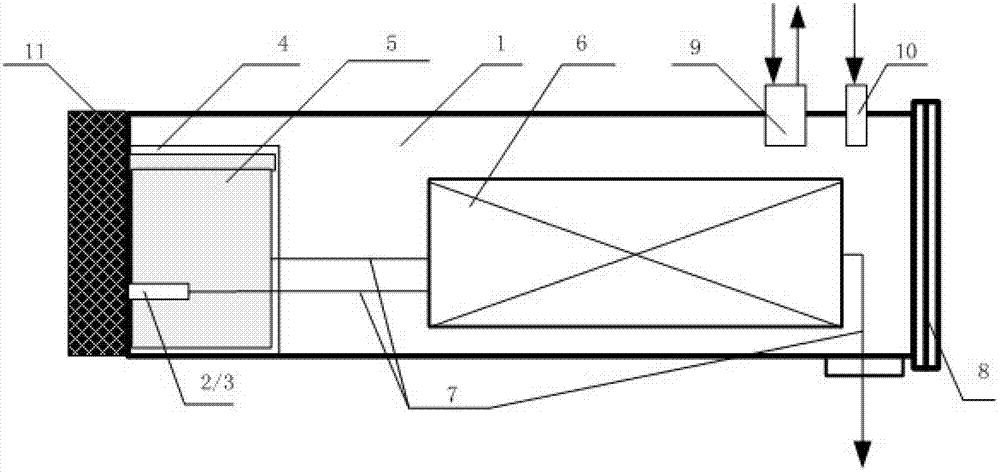

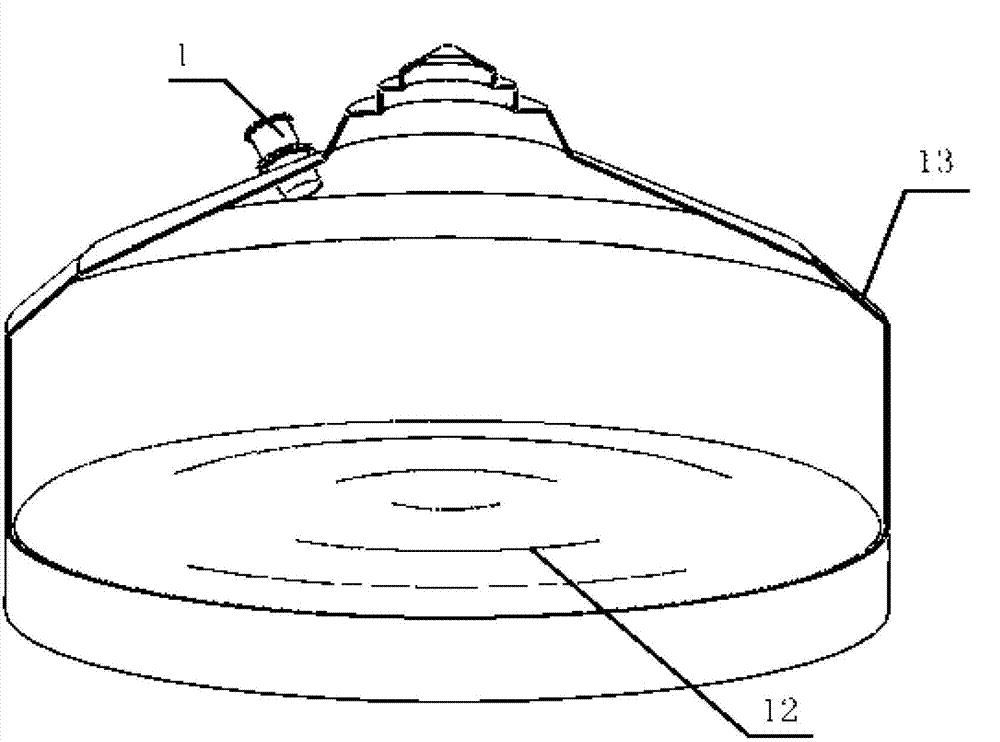

[0044] The specific implementation manner of the present invention will be described below in combination with the three-dimensional figure of the combined measuring device.

[0045] The concrete installation implementation process of device of the present invention is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

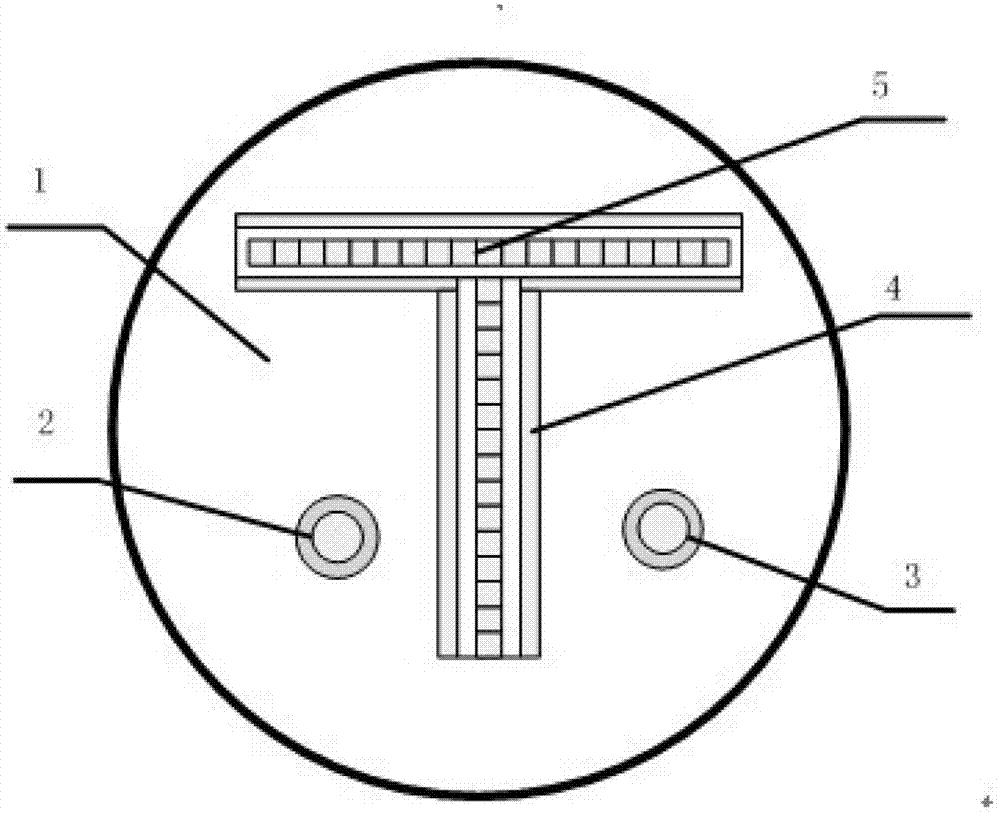

The invention brings forward a combined system for measuring blast furnace burden surface. Three apparatuses including a multiple-input-multiple-output MIMO radar and antenna array, a visible light or infrared light video camera and a laser rangefinder are combined to form a system. The device provided by the invention comprises a video monitoring system and a laser rangefinder system. A multiple-input-multiple-output MIMO radar burden surface measuring system, the video monitoring system and the laser rangefinder system are integrated into a blast furnace roof radar system cooling protective cover. The device also comprises a display and image processing system. The display and image processing system is adopted to simultaneously realize display and comparison of three measuring systems and carry out data fusion, data exchange and data verification. On a computer, one or more different measuring combinations are respectively selected according to different situations so as to realize dynamic measuring requirements of burden surface of different precisions, different imaging speeds and different resolutions and provide different measuring methods.

Description

[0001] technical field [0002] The present invention proposes a system for combined measurement of blast furnace material level, which consists of multiple-input multiple-output MIMO radar and antenna array, visible light or infrared video camera, and laser rangefinder to form a system, which assist each other and use their own measurement The advantage is to achieve the function of monitoring the dynamic material level and its online material level display. [0003] Background technique [0004] The monitoring of the material level in the blast furnace is very important in steel production. On the one hand, through the observation of the material level, the distribution of the furnace material in the blast furnace can be known, so that the production personnel can carry out targeted control on the next distribution according to the distribution of the material level. To improve production efficiency; on the other hand, when the distribution of the material surface in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21B7/24

Inventor 陈先中尹怡欣侯庆文许鼎

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com