Five-cereal soymilk and manufacture method

A five-grain soybean milk and formula technology, which is applied in dairy products, milk substitutes, applications, etc., can solve the problems that five-grain soybean milk is prone to stratification or precipitation, affecting the appearance and appetite of soybean milk, and achieves the effect of unique flavor, ensuring appetite and increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

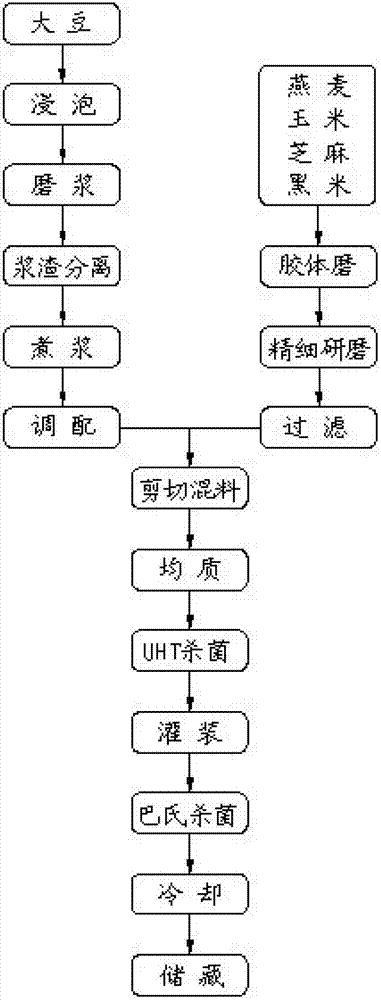

[0033] Embodiment 1: a kind of five-grain soybean milk and its preparation method

[0034] See attached figure 1 As shown, a five-grain soybean milk, the raw material formula of the five-grain soybean milk is composed of the following materials in mass percentage:

[0035] Water 82-86%;

[0036] soybean 10-12%;

[0037] Sucrose 2-3%;

[0038] Oats 0.5-1%;

[0039] Black rice 0.5-1%;

[0040] Black sesame 0.5-1%;

[0041] Corn 0.5-1%;

[0042] Emulsifier 0.2-0.4%;

[0043] Fragrance 0.03-0.07%;

[0044] Sweetener 0.02-0.06%.

[0045] The production method includes heating soybean milk to 98-100°C, mixing oats, corn, sesame and black rice, and grinding to obtain a cereal slurry; mixing soybean milk with the cereal slurry, adding sucrose, spices and emulsifiers to obtain a mixed liquid; the mixed liquid is homogenized under the condition of a pressure of 35-40 MPa to obtain a homogeneous liquid, and the homogeneous liquid is sterilized and then cooled and filled to obta...

Embodiment 2

[0054] Embodiment 2: a kind of five-grain soybean milk and its preparation method

[0055] See attached figure 1 Shown: a five-grain soybean milk and its preparation method, the raw material formula of the five-grain soybean milk is composed of the following materials in mass percentage:

[0056] Water 85 kg;

[0057] soybeans 10 kg;

[0058] Sucrose 2 kg;

[0059] Oats 0.8 kg;

[0060] 0.8 kg of black rice;

[0061] 0.8 kg black sesame;

[0062] 0.8 kg of corn;

[0063] Emulsifier 0.3 kg;

[0064] Vanillin 0.03 kg;

[0065] Flavor 0.02 kg;

[0066] Ethyl maltol 0.02 kg;

[0067] Acesulfame K 0.02 kg.

[0068] Described preparation method comprises the following steps:

[0069] 1. Raw material acceptance: inspectors monitor the appearance, protein, moisture, and abnormal beans according to the raw material standards of soybeans and grains, and receive and put into storage if they meet the requirements.

[0070] 2. Cleaning and soaking: Put the quantitative soybeans ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com