Method And Insert For Manufacturing A Multi-density Shoe Sole

A multi-density, plug-in technology, used in footwear, applications, heels, etc., to solve problems such as the need for factory space and a large number of machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

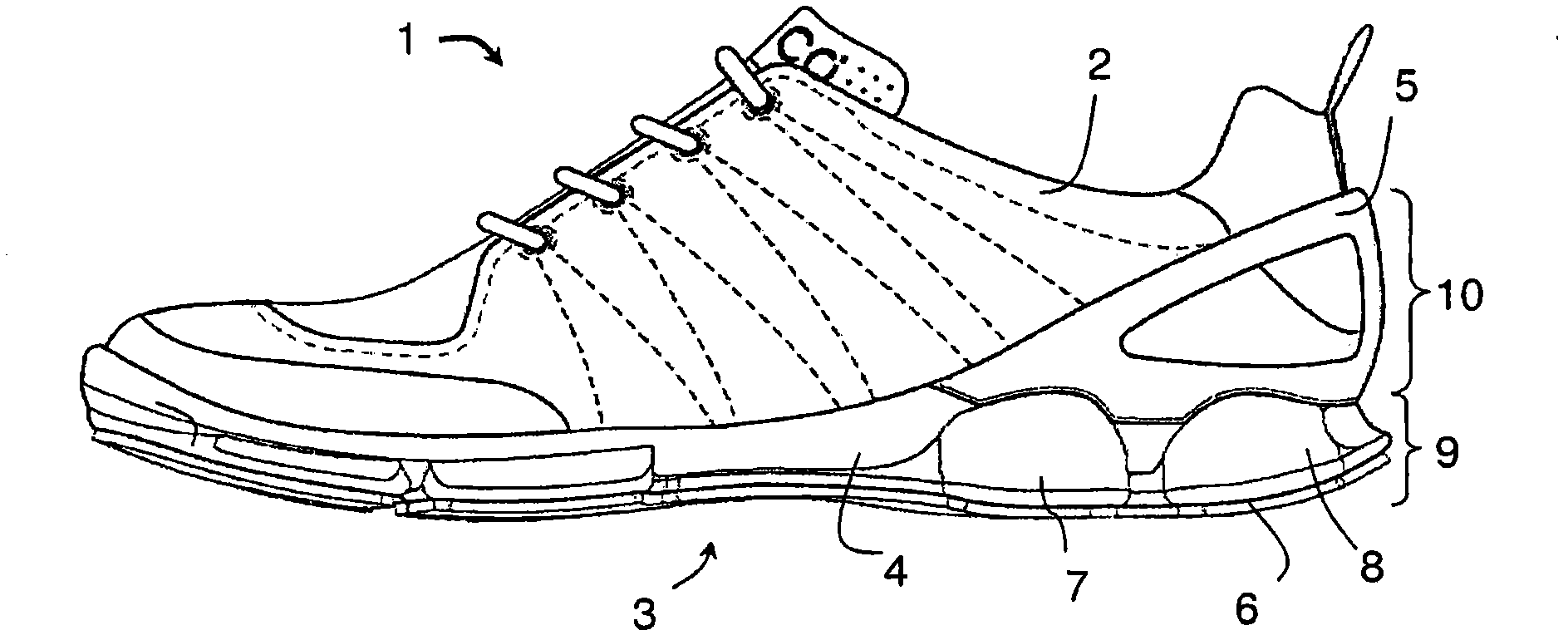

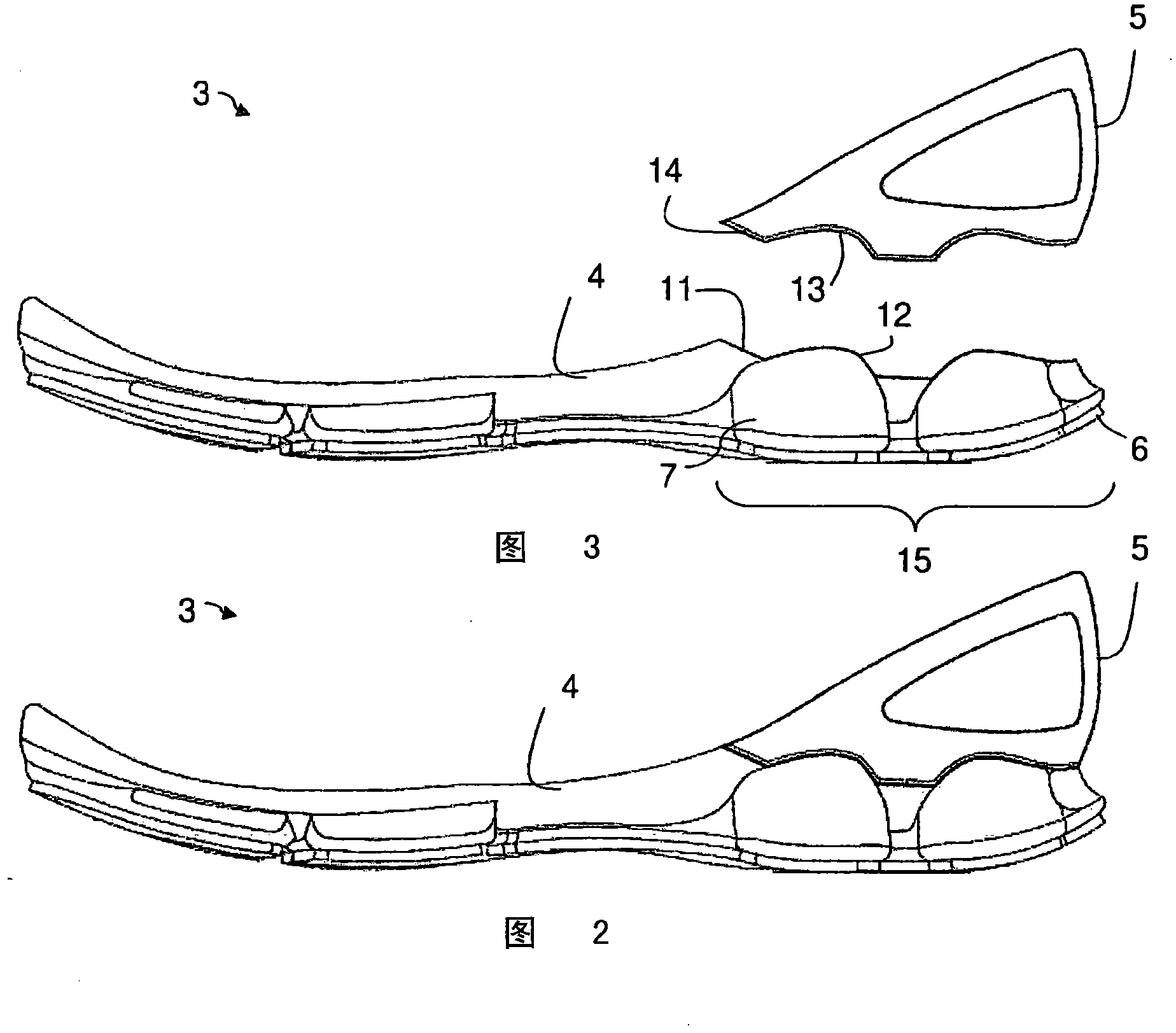

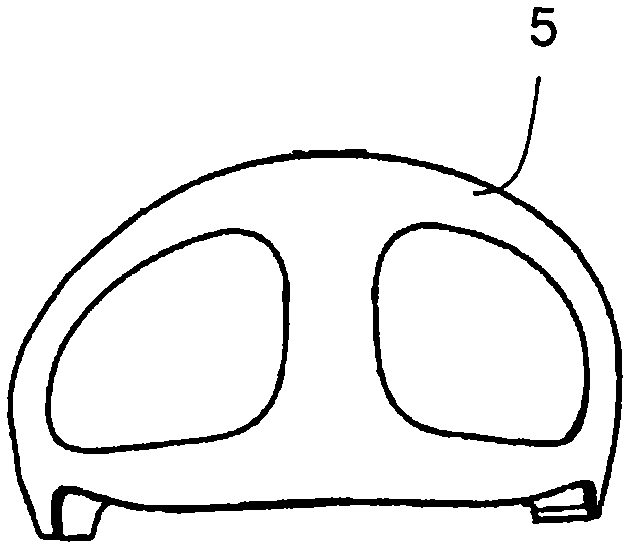

[0028] figure 1 The finished product of the invention is shown, a shoe 1 manufactured with a multidensity sole 3 according to the method of the invention. In this preferred embodiment, the sole consists of a midsole 4, a heel cap 5 and an outsole 6, usually a TPU outsole. Posts 7 and 8 in the lower heel 9 are provided to stabilize the foot during walking. In the upper heel portion 10, the heel cap 5 ensures a firm grip 180 degrees around the wearer's heel. In order to ensure this firm grip, the heel cap 5 is composed of a polyurethane having a higher density than that used for the midsole 4 . Thus, instead of using only one type of polyurethane for the midsole 4 and the heel cap 5, polyurethanes of different densities are used to achieve different sole properties at different locations. figure 2 showing the sole 3 without the upper 2, image 3 The heel cap 5 is shown as a separate part of the sole. As will be explained later, the heel cap is initially produced in a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com