Oleaginous composition and oil-in-water type emulsifier containing oleaginous composition

A technology of oil composition and oil-in-water type, which is applied in the direction of edible oil/fat, edible oil/fat phase, dairy products, etc. It can solve the problems of coarse palm oil crystallization and poor cream stability, and achieve excellent mouth melting , Inhibition of changes in physical properties, good mouth melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The method for preparing the oil-in-water emulsion of the present invention is not particularly limited, and it can be prepared by a conventionally known method. For example, it can be prepared by preparing an oil phase and a water phase containing the oil and fat composition of the present invention, mixing the oil phase and the water phase, and homogenizing the obtained emulsion. . Moreover, sterilization treatment can also be performed as needed. Homogenization treatment may be pre-homogenization performed before sterilization treatment, post-homogenization performed after sterilization treatment, and secondary homogenization in which both pre-homogenization and post-homogenization are combined may be performed. Preferably, cooling and aging steps are taken after the homogenization treatment.

[0061] When the oil-in-water emulsion of the present invention contains milk fat, it can be prepared by adding milk fat to the oil composition of the present invention to pr...

Embodiment

[0065] Hereinafter, the present invention will be described in detail with examples. However, the present invention is not limited to these examples. All the % described below are mass %.

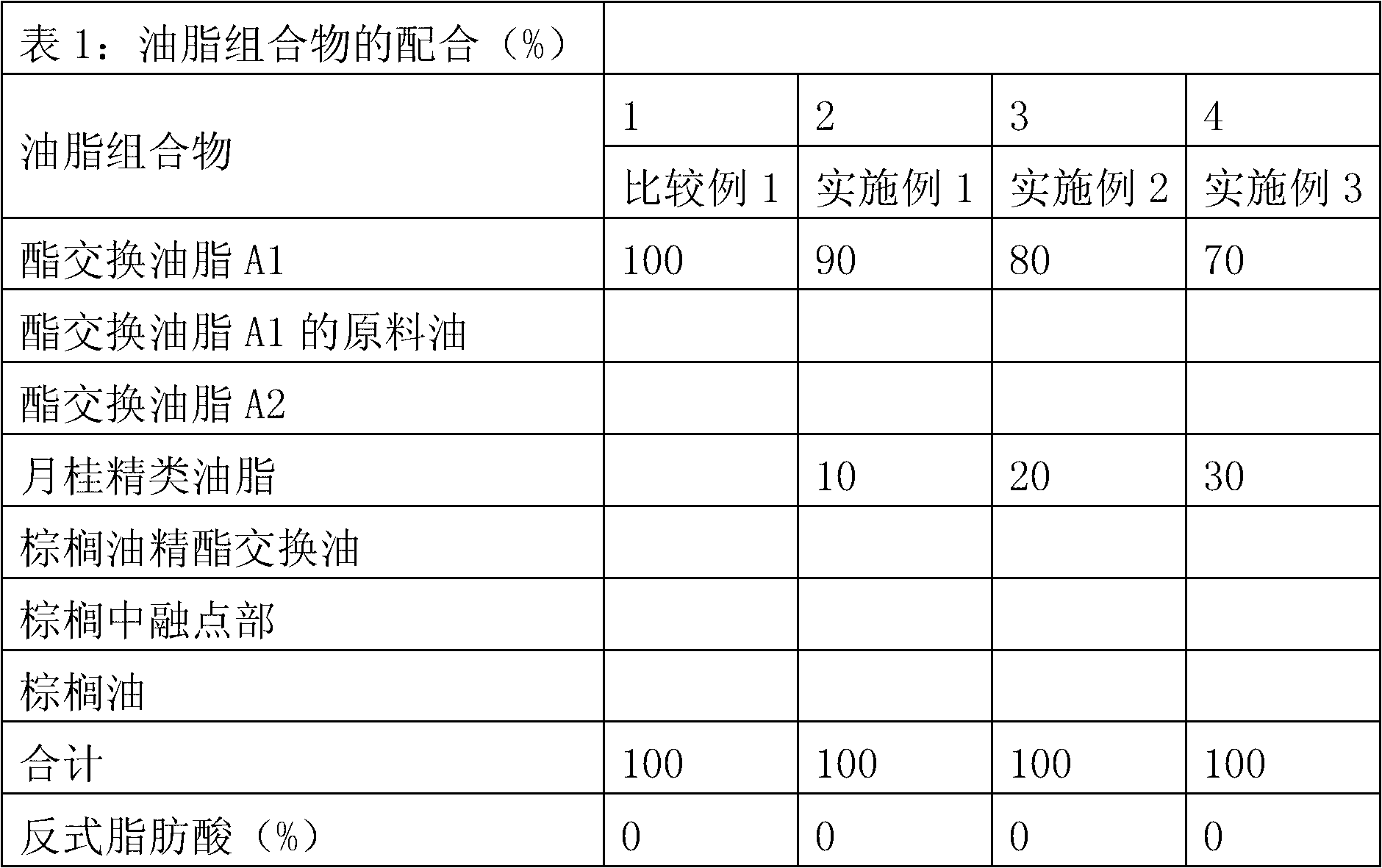

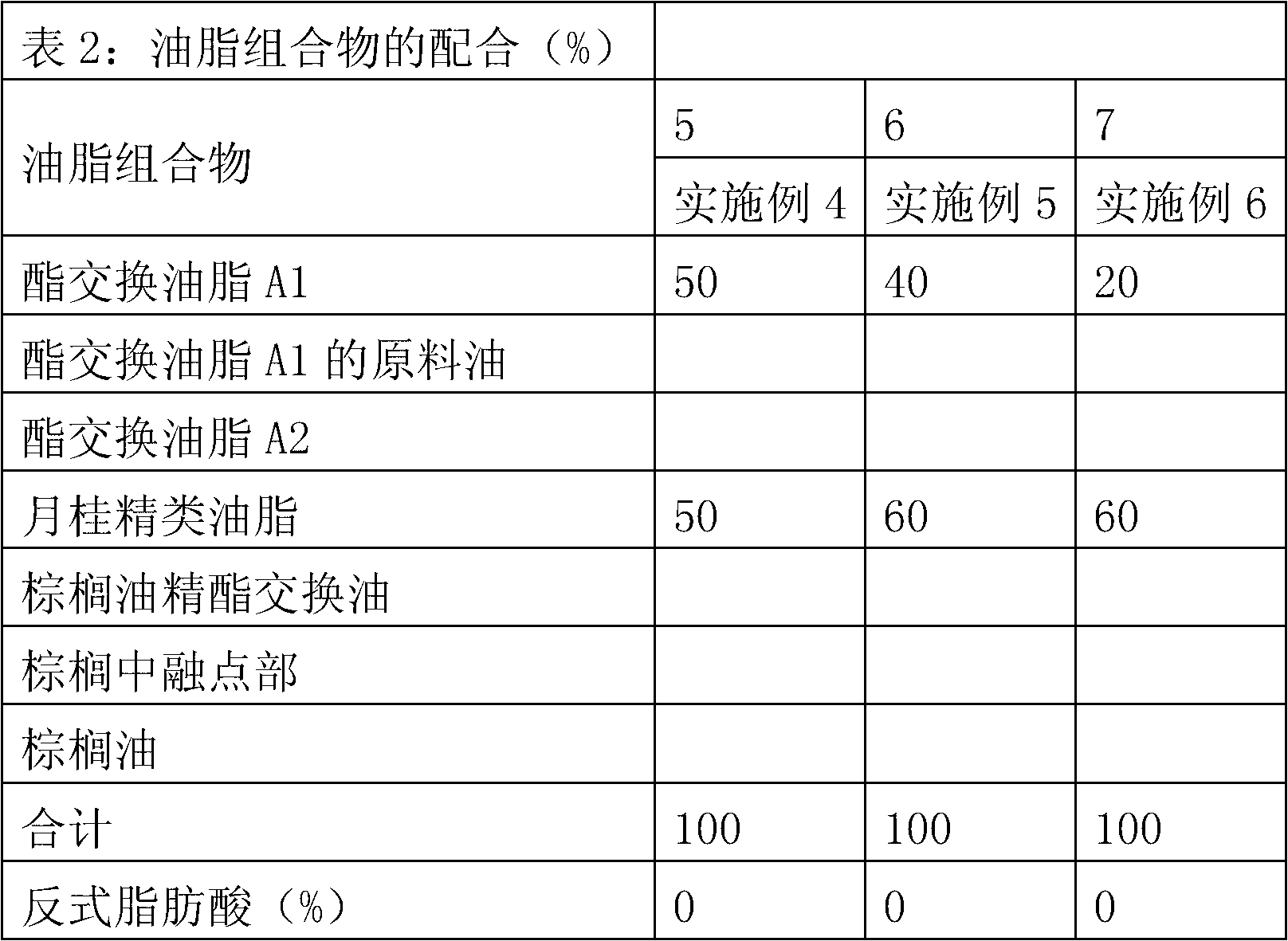

[0066] Tables 1-4 have shown the compounding and trans fatty acid content of oil-fat compositions 1-14. Fat and fat compositions 1-14 are Examples 1-9 and Comparative Examples 1-5.

[0067] And the oil-in-water emulsion (cream) which can be whipped about 45% of the oil content shown in Table 5 was obtained using fat-fat compositions 1-14. Each cream using oil-fat compositions 1-14 is Examples 10-18 and Comparative Examples 6-10. The evaluation results of the oil-in-water emulsion (cream) are described in Tables 6-9.

[0068] (Preparation of fat composition)

[0069] The raw material fats and oils listed in Tables 1 to 4 were dissolved, and the necessary amount was measured and mixed, and then spirally stirred for 30 minutes while maintaining at 60° C., thereby preparing a homogeneous o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com