Electrical connector and contact element thereof

A technology of electrical connectors and contacts, which is applied in the direction of connection, parts of connection devices, fixed/insulated contact components, etc., can solve the problems of increased production cycle, increased manufacturing cost, and complicated assembly process, so as to simplify the manufacturing process and structure, time saving, and manufacturing cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

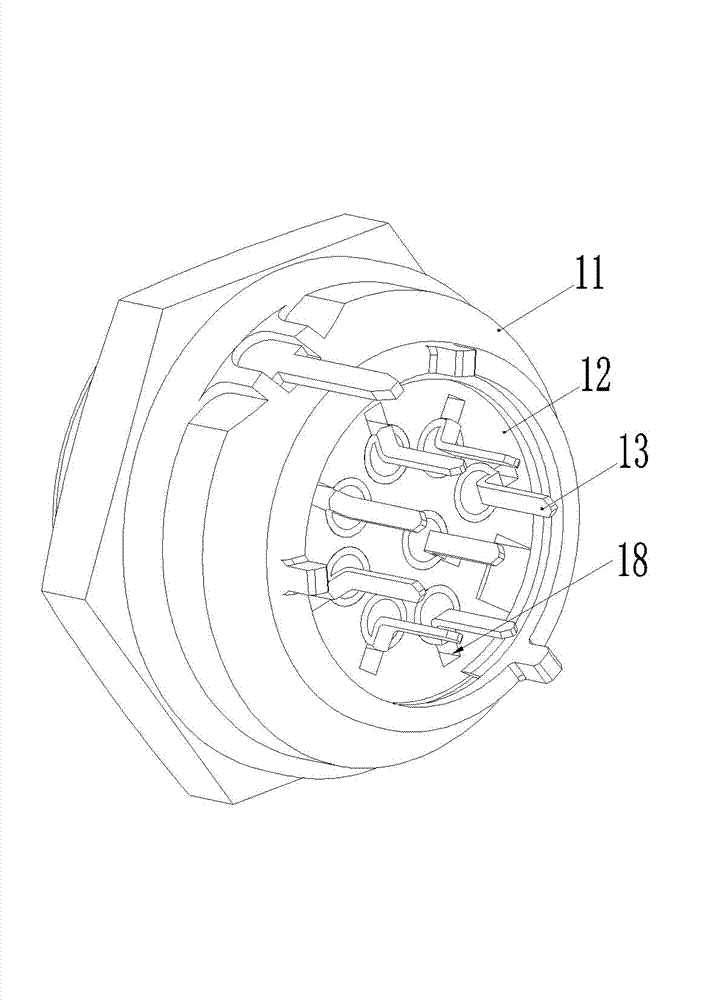

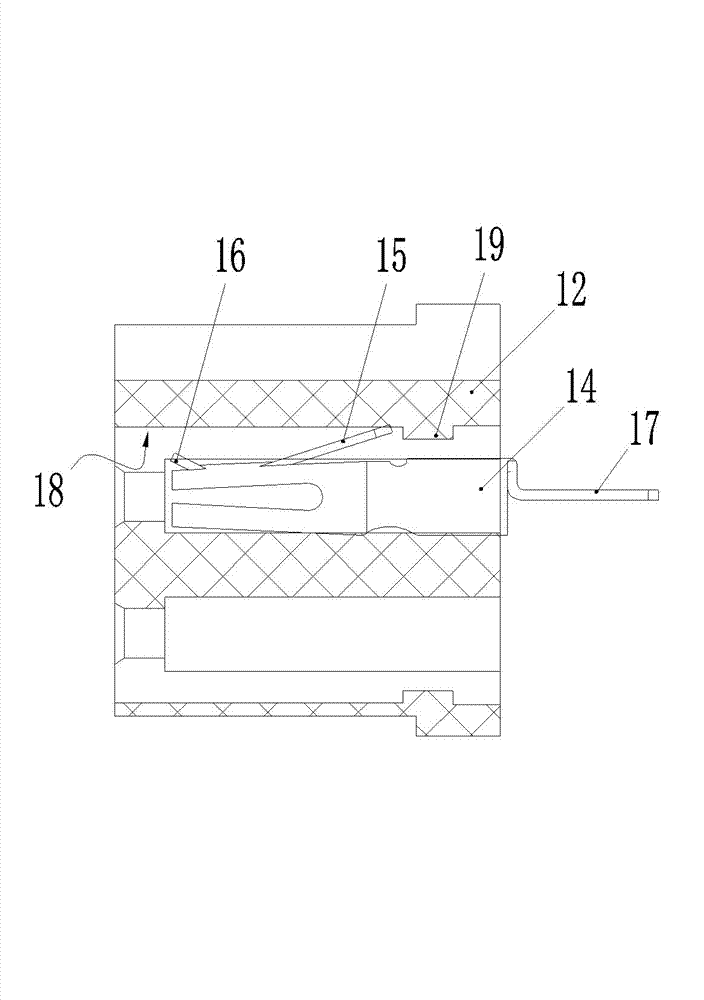

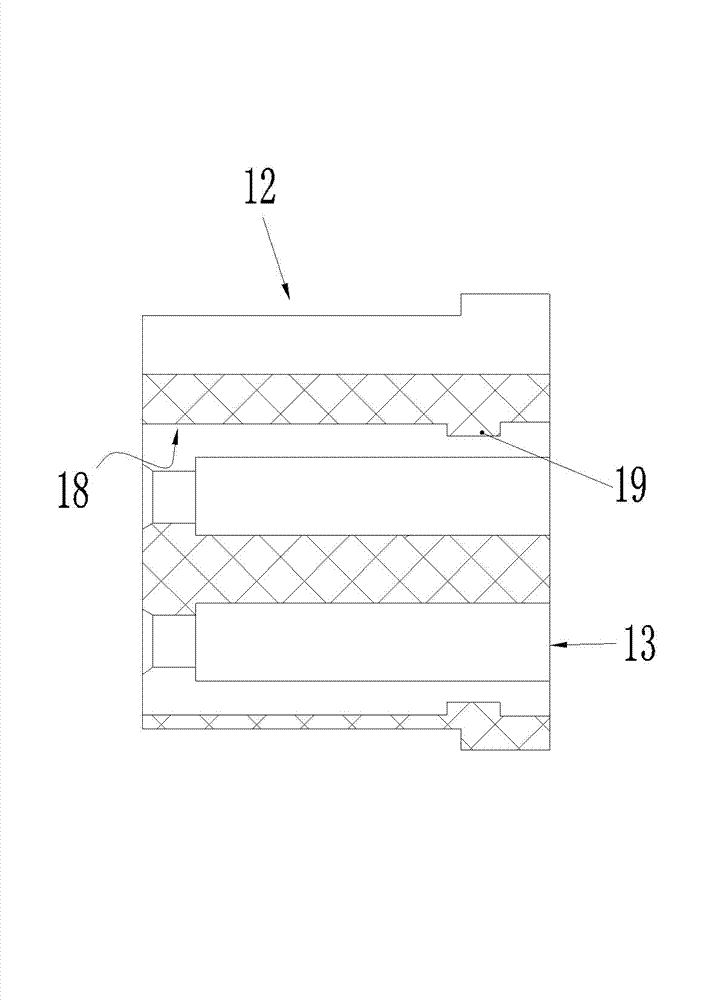

[0025] Embodiment 1 of the electrical connector of the present invention, such as Figure 1-4 As shown, a metal shell 11 is included, and an insulator 12 is fixedly installed in the shell 11. A mounting hole 13 is provided on the insulator 12, and a contact piece 14 is installed in the mounting hole 13. The contact piece 14 is a hole contact The component includes a base, the base is cylindrical and has an axis extending in the front-rear direction (plugging direction), the front part has a socket 14-1 for the insertion of the adapter pin, and the outer peripheral surface of the base is provided with elastic inversions. Thorn 15. In this embodiment, the elastic barb 15 is integrated with the base of the corresponding contact piece. The direction perpendicular to the front and back direction) extends outside and forms an overhanging structure, and a finger key 16 is also provided on the outer wall of the base of the contact piece 14. In this embodiment, the finger key 16 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com