Determination method of enzyme activity of collagenase

A collagenase and determination method technology, applied in the measurement of color/spectral properties, etc., can solve the problems of substrate difference, inconsistent enzyme activity data, inconsistent detection standards of collagenase enzyme activity, etc., achieving simple instrument, convenient operation, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] ①Reagent preparation

[0037] (1) 0.1mol / L Tris·Cl buffer (containing 50mmol CaCl 2, pH7.5): Weigh 3.15g Tris·Cl and dissolve it in 200mL distilled water, add 1.11g calcium chloride, fully dissolve and adjust the pH to 7.5 with 3mol / L NaOH;

[0038] (2) 10% trichloroacetic acid (TCA) solution: mix 50mL of trichloroacetic acid with 450mL of distilled water;

[0039] (3) 0.6mol / L o-phthalaldehyde solution: dilute 0.6mol o-phthalaldehyde to 1L with distilled water;

[0040] (4) 0.3mmol / L hydroxyproline standard solution: weigh 39.4mg of hydroxyproline, dissolve it in distilled water, and dilute to 1L;

[0041] (5) 2mol / L acetic acid buffer solution: dissolve 2mol of sodium acetate with distilled water, and dilute to 1L, dilute 2mol of acetic acid with distilled water to 1L, and then mix the above sodium acetate solution and acetic acid solution at a volume ratio of 43:7 , the pH is 5.4;

[0042] (6) Ninhydrin chromogenic solution: mix 85mg ninhydrin hydrate and 15mg re...

Embodiment 2

[0057] 1. reagent preparation: with embodiment 1, difference is that the concentration of o-phthalaldehyde is 0.8mol / l;

[0058] ② Hydroxyproline gradient sample preparation: pipette 0.1, 0.2, 0.4, 0.5, 0.6, 0.8, 1.0mL of hydroxyproline standard solution into 25ml colorimetric tubes, make up to 1mL with distilled water, and dilute to the concentration For 7 hydroxyproline gradient samples of 0.03, 0.06, 0.12, 0.15, 0.18, 0.24, and 0.30 μmol / mL, take 1.0ml of distilled water in a 25ml colorimetric tube as a reference sample;

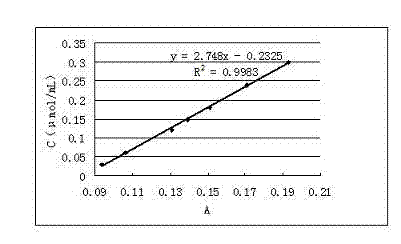

[0059] ③ Hydroxyproline Gradient Sample Determination: The operating conditions are the same as in Example 1, except that the temperature of the water bath is 105° C., and the time is 15 minutes. The standard curve formula is fitted: C=2.7483A-0.2328.

[0060] ④Preparation of enzymatic hydrolysis solution to be tested: Weigh 1.2mg insoluble collagen, add 0.6mL 0.1mol / L Tris Cl buffer solution, preheat at 40°C for 12min, then add 0.1mL enzyme solution, rea...

Embodiment 3

[0069] 1. reagent preparation: with embodiment 1, difference is that the concentration of o-phthalaldehyde is 0.7mol / l;

[0070] ② Hydroxyproline gradient sample preparation: pipette 0.1, 0.2, 0.3, 0.4, 0.6, 0.7, 0.8, 1.0mL of hydroxyproline standard solution into 25ml colorimetric tubes, make up to 1mL with distilled water, dilute 8 hydroxyproline gradient samples with concentrations of 0.03, 0.06, 0.12, 0.15, 0.18, 0.21, 0.24, and 0.30 μmol / mL were prepared, and 1.0ml of distilled water was taken in a 25ml colorimetric tube as a reference;

[0071] ③ Hydroxyproline Gradient Sample Determination: The operating conditions are the same as in Example 1, except that the temperature of the water bath is 102° C. and the time is 18 minutes; the formula of the standard curve is obtained by fitting: C=2.7488A-0.2432.

[0072] ④Preparation of enzymatic solution to be tested: Weigh 1.0mg of insoluble collagen, add 0.5mL 0.1mol / L Tris Cl buffer solution, preheat at 37°C for 10min, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com