Bearing seat sealing device for centrifugal fan

A centrifugal fan and sealing device technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve problems such as poor sealing, achieve convenient assembly, small size, and prevent oil leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

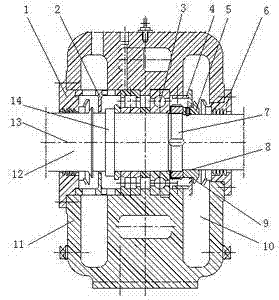

[0027] The retaining ring I2 is sleeved on the main shaft, one side is close to the outer ring of the bearing 3, and the other side is close to the sealing sleeve I1. The radial clearance between the retaining ring I2 and the main shaft is 0.3mm.

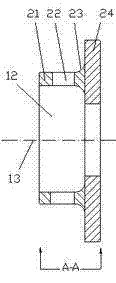

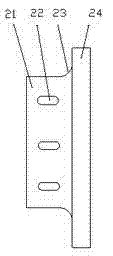

[0028] like figure 2 , image 3 As shown, the retaining ring II4 is welded by the vertical file 24 and the cross bar 21, and its axial section is a double T-shaped structure lying on its side. The screw hole on the crosspiece 21 is a long waist hole 22, which is convenient for adjusting the gap between the vertical rail 24 and the ring edge 9 when the retaining ring II4 is installed; Washers with different thicknesses are used to adjust the gap between the vertical rail 24 and the bearing seat 11 . The vertical rail 24 is perpendicular to the main shaft, and the cross rail 21 is parallel to the central axis 13 of the main shaft.

[0029] The oil slinger 5 is composed of a ring sleeve 8 and a ring edge 9 . The vertical file 24 o...

Embodiment 2

[0031] The retaining ring I2 is sleeved on the main shaft, and the other side of the retaining ring I2 is fastened to the bearing seat 11. The radial clearance between the retaining ring I2 and the main shaft is 0.4mm.

[0032] Retaining ring Ⅱ4 such as figure 2 , image 3 As shown, the crosspiece 21 of the retaining ring II4 is screwed together with the bearing seat 11, the vertical piece 24 is perpendicular to the main shaft, and the crosspiece 21 is parallel to the central axis 13 of the main shaft.

[0033] The radial gap between the vertical file 24 and the ring sleeve 8 is 0.4 mm; the axial gap between the vertical file 24 and the ring edge 9 is 0.8 mm.

[0034] The welding part of the vertical rail 24 and the cross rail 21 is a rounded corner 23 to reduce the stress generated during welding;

[0035] When the above embodiment 1 and embodiment 2 are working, the lubricating oil will splash out from the bearing 3 under the rotation of the high-speed main shaft and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com