Thermosetting resin and preparation method thereof, carrier and electrostatic charge image developer

An electrostatic charge image and thermoplastic resin technology, applied in the field of developer and carrier for electrostatic charge image development, can solve the problem that it is difficult to balance the bonding force between the coating resin and the magnetic core material, and the charge stability of the carrier can achieve internal pollution evaluation Excellent, sufficient bond strength, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

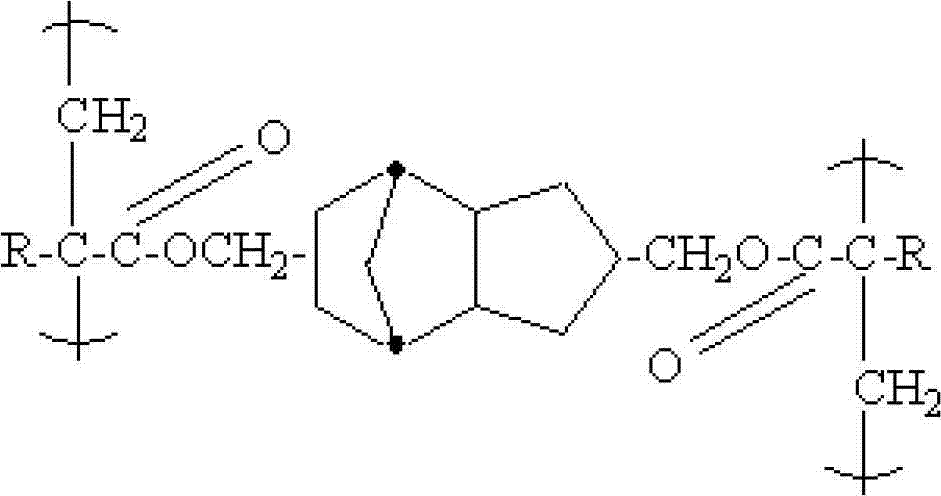

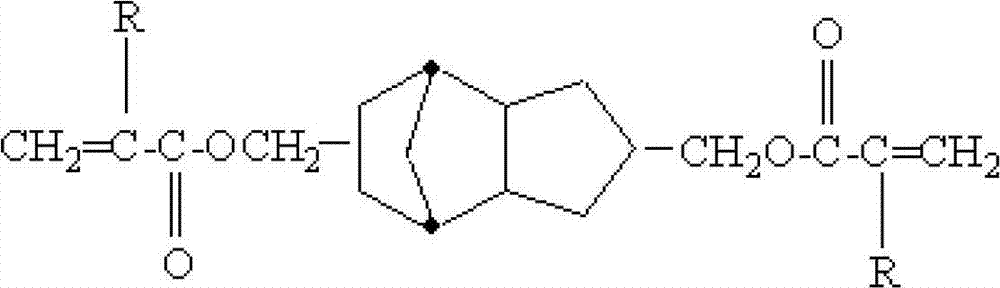

Method used

Image

Examples

Embodiment 1

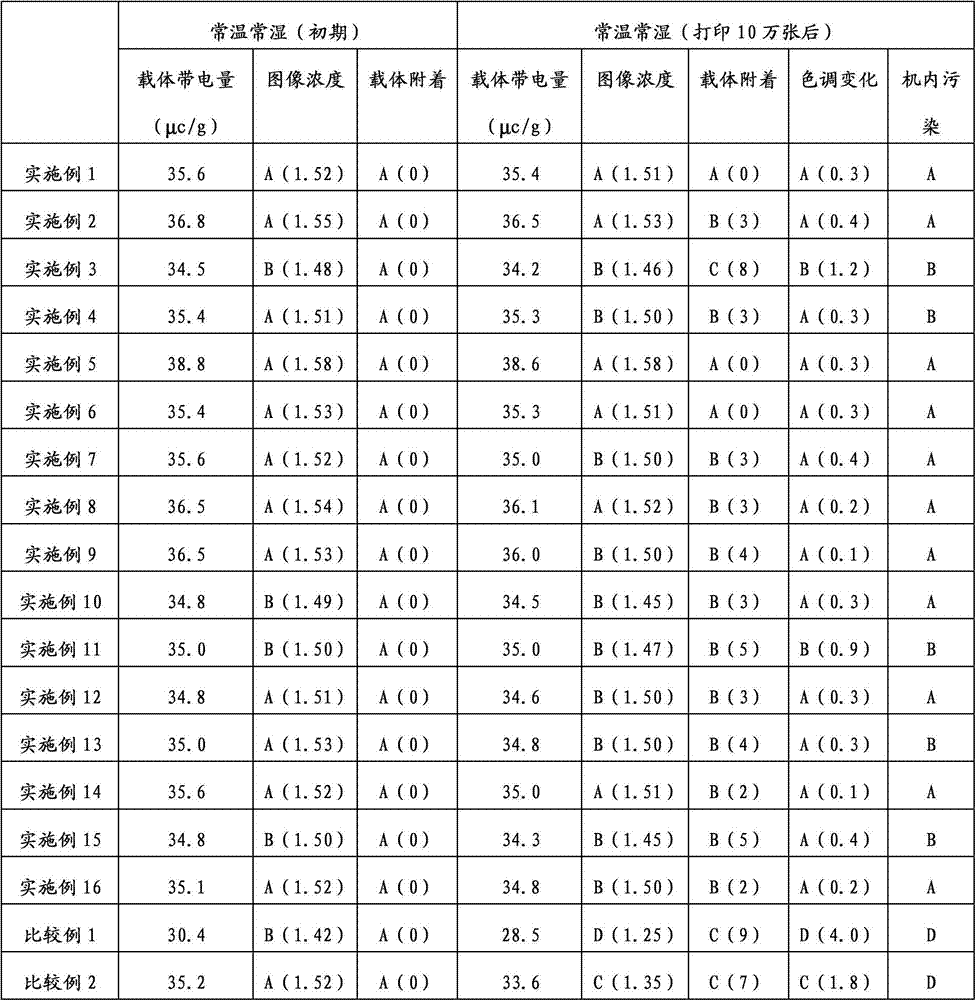

[0125] Mix 8 parts of cyan toner with 92 parts of carrier 1, and mix in a mixer for 10 minutes to prepare a cyan two-component developer. The absolute value of the triboelectric charge amount when the above-mentioned toner and carrier were mixed for 10 minutes was defined as the initial triboelectric charge amount. Simultaneously, 95 parts of cyan toner was mixed with 5 parts of carrier 1 to prepare a cyan supplementary developer.

[0126] Using a commercially available color copier (printing speed: color 50ppm, black and white 65ppm. Transformed into a test machine) as an image forming device, put the above-mentioned cyan two-component developer in the cyan position of the developing device, and put the cyan supplementary developer in At the corresponding locations, an image forming test was performed under a normal temperature and normal humidity (20° C. / 50% RH) environment. After printing is completed, initial evaluation and durability test are performed.

[0127] 100,000...

Embodiment 2~16

[0162] In Example 1, evaluation was performed under the same conditions except that the carrier 1 was replaced with carriers 2 to 16 . The evaluation results are shown in Table 1.

Embodiment 17

[0170] Mix 8 parts each of yellow toner, magenta toner, cyan toner, and black toner with 92 parts of carrier 1 respectively, and mix each in a mixer for 10 min to prepare a 4-color two-component development agent. Simultaneously, 95 parts each of yellow toner, magenta toner, cyan toner, and black toner were mixed with 5 parts of carrier 1 respectively to prepare 4-color supplementary developers.

[0171] Use a commercially available color copier (printing speed: 50ppm for color, 65ppm for black and white. Transformed into a test machine) as an image forming device, put the above-mentioned 4-color two-component developer in the corresponding 4-color position in the developing device, and place the 4-color The supplementary developer was placed in the corresponding position, and the image formation test was carried out under normal temperature and normal humidity (20°C / 50%RH) and high temperature and high humidity (30°C / 80%RH) environments. After printing is completed, initial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com