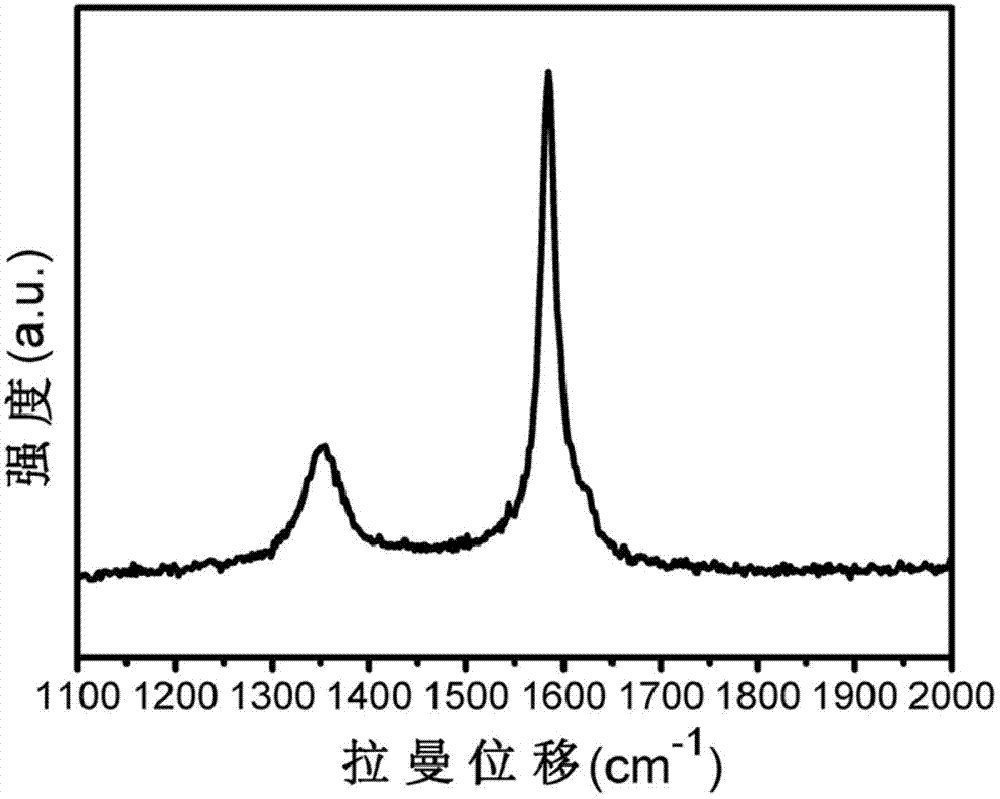

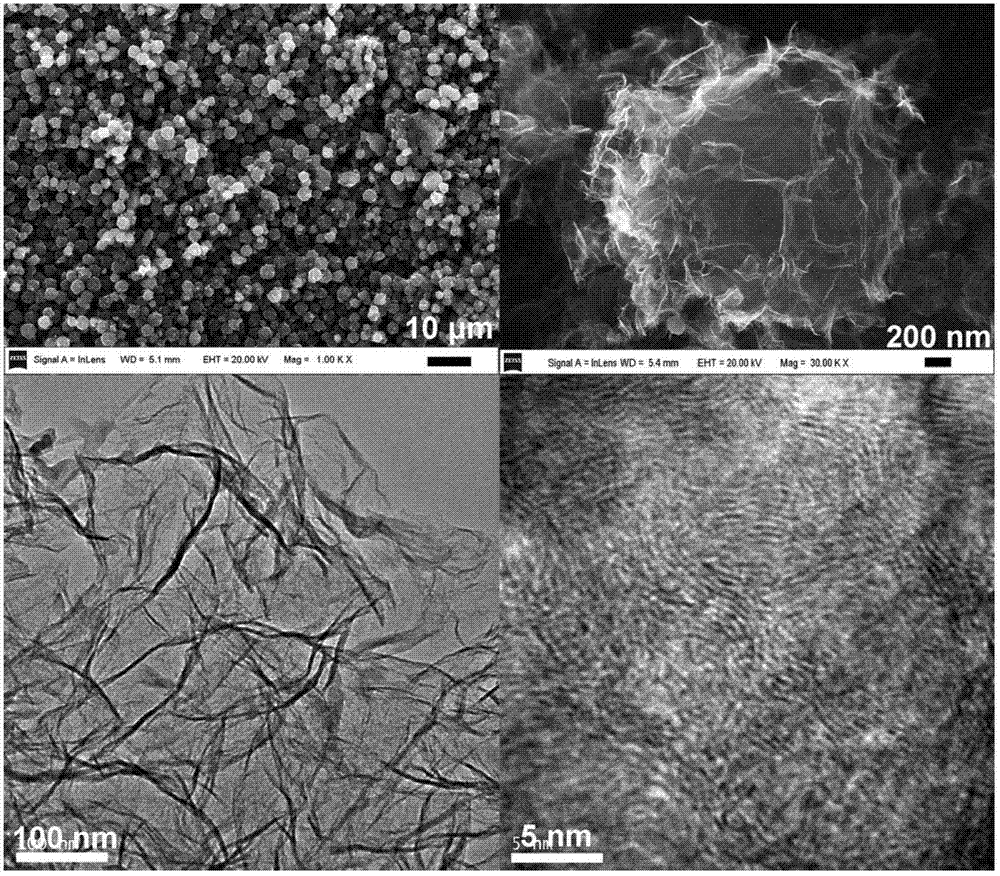

Graphene spherical assembly and preparation method thereof

An assembly and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of complex process, high cost, unfavorable industrialization, etc., and achieve the effect of simple process, high purity and yield, and low requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

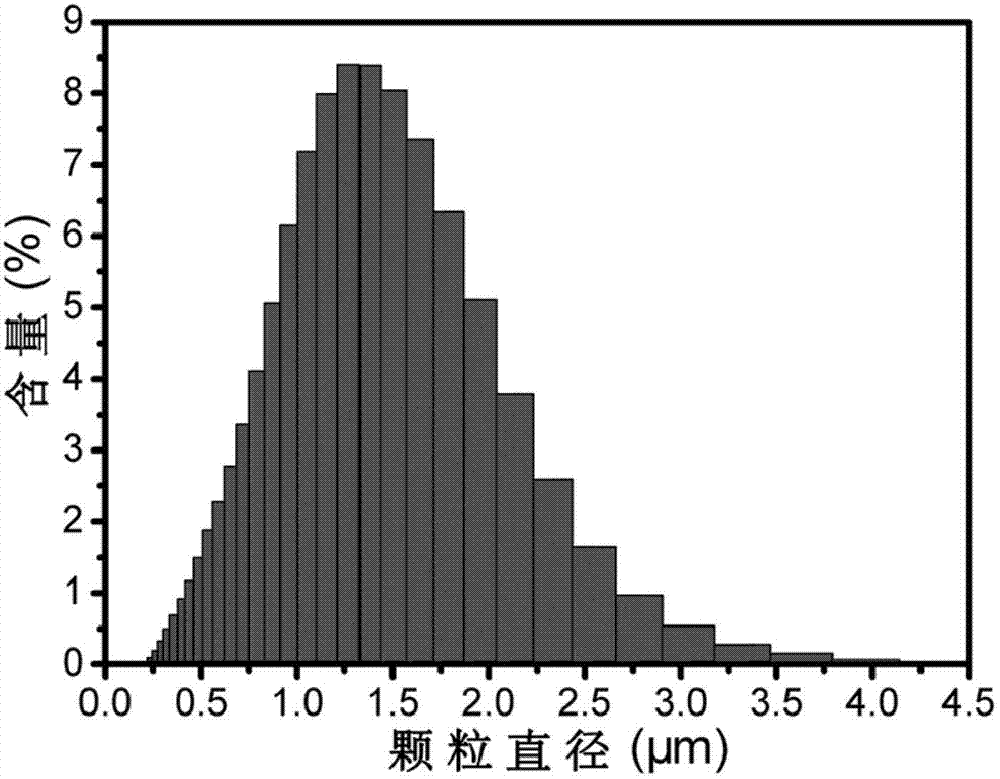

[0023] Take by weighing 3.37g ferrocene (Fe(C 5 h 5 ) 2), 3.91g of o-cresol and 1.74g of sublimed sulfur were stirred and mixed (atomic ratio Fe:S=1:3), and then the mixture was transferred into the reactor, and the reactor was filled with benzene and sealed with a cover. Place the reaction kettle in a 700-watt ultrasonic water bath and vibrate for 30 minutes, take it out and put it in a constant temperature oven at 200°C for 48 hours. After the reaction kettle is naturally cooled to room temperature, the product is suction-filtered, and the obtained solid product is under the protection of nitrogen flow. Carbonization treatment was carried out at 1000°C for 2 hours to obtain a black solid powder. Put the powder in excess 5M hydrochloric acid solution and stir for 72 hours, then filter with suction and wash the filtrate with a large amount of deionized water until the pH value of the eluate is equal to 7, and then dry the filtrate under vacuum at 80°C That is, a graphene sp...

Embodiment 2

[0030] Weigh 4.89g ferric chloride (FeCl 3 ·6H 2 O), 3.91g of o-cresol and 5.80g of sublimed sulfur were stirred and mixed (atomic ratio Fe:S=1:10), and then the mixture was transferred into a reactor, and the reactor was filled with benzene and sealed with a cover. Place the reaction kettle in a 700-watt ultrasonic water bath and vibrate for 30 minutes, take it out and put it in a constant temperature oven at 250°C for 4 hours. After the reaction kettle is naturally cooled to room temperature, the product is suction-filtered, and the obtained solid product is carried out under the protection of nitrogen flow. Carbonization treatment was carried out at 600°C for 2 hours to obtain a black solid powder. Put the powder in excess 5M hydrochloric acid solution and stir for 72 hours, then filter with suction and wash the filtrate with a large amount of deionized water until the pH value of the eluate is equal to 7, and then dry the filtrate under vacuum at 80°C That is, a graphene...

Embodiment 3

[0033] Take by weighing 7.32g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 3.98g of catechol and 0.58g of sublimed sulfur were stirred and mixed (atomic ratio Fe:S=1:1), and then the mixture was transferred into a reactor, and the reactor was filled with benzene and sealed with a cover. Place the reaction kettle in a 700-watt ultrasonic water bath and vibrate for 30 minutes, take it out and put it in a constant temperature oven at 200°C for 60 hours. After the reaction kettle is naturally cooled to room temperature, the product is suction-filtered, and the obtained solid product is under the protection of nitrogen flow. Carbonization treatment was carried out at 800°C for 2 hours to obtain a black solid powder. Put the powder in excess 5M hydrochloric acid solution and stir for 72 hours, then filter with suction and wash the filtrate with a large amount of deionized water until the pH value of the eluate is equal to 7, and then dry the filtrate under vacuum at 80°C That is, a graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com