Production device for sodium bisulfide continuous absorption reaction

A sodium hydrosulfide and production device technology, which is applied in the field of chemical production equipment manufacturing, can solve problems such as large power consumption, many operating steps, and frequent equipment start and stop, and achieve the effects of reducing power consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

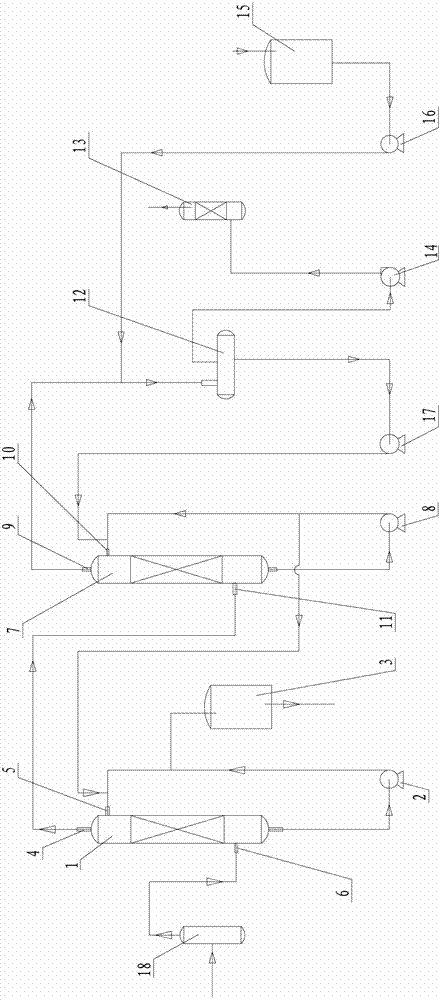

[0023] Such as figure 1 Shown is in a kind of production process provided by the present invention, power consumption is little, production cost is low, the production device of the sodium hydrosulfide continuous absorption reaction that product quality is easy to control. The production unit of the sodium hydrosulfide continuous absorption reaction comprises an absorption tower 1, an absorption tower bottom pump 2 and a sodium hydrosulfide product solution storage tank 3, a process tail gas output interface 4 is arranged at the top of the absorption tower 1, and a process absorption liquid is arranged on the top The input interface 5, the lower part is provided with the hydrogen sulfide gas input interface 6, the input end of the absorption tower bottom pump 2 is connected to the bottom of the absorption tower, and the output end is respectively connected to the process absorption liquid input interface 5 and the sodium hydrogen sulfide product solution storage tank 3. An abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com