SNCR (selective non-catalytic reduction) denitration device and method for rotary cement kiln

A cement rotary kiln and denitrification technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve problems affecting SNCR denitrification performance, achieve the effects of suppressing negative effects, improving denitrification performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

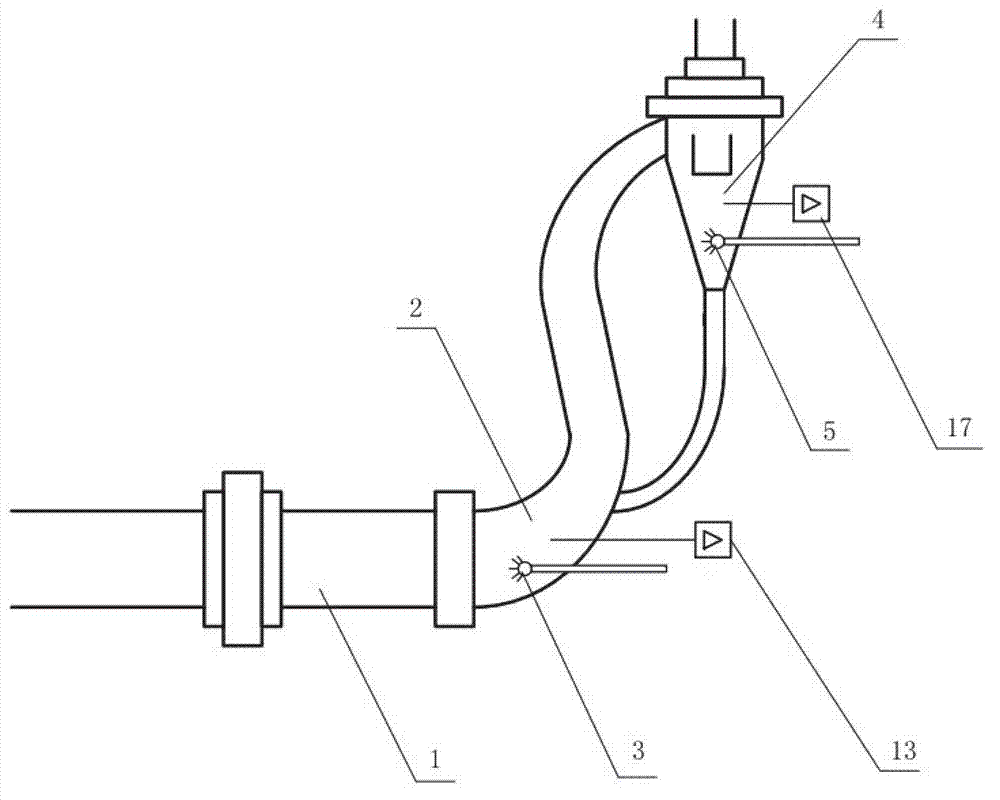

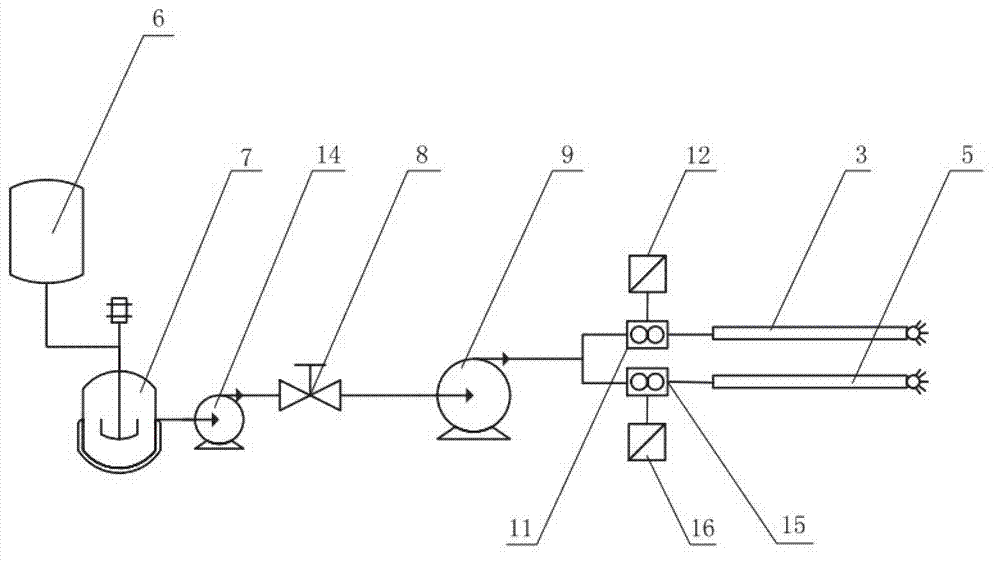

[0028] The reducing agent used is urea, and the ammonia to nitrogen ratio is 1.0. The first-level spray gun 3 is installed at the position of the tail 2 of the cement rotary kiln at a temperature of 1100℃; x Online detection instrument 13 detects NO in flue gas x The concentration is 1000 mg / Nm 3 , After spraying urea, NO x Online detection instrument 13 detects NO in flue gas x The concentration becomes 210mg / Nm 3 , The actual denitrification efficiency after the first-level spray gun 3 is sprayed with urea is 79%; the second-level spray gun 5 is placed at the bottom of the decomposition furnace 4 at a temperature of about 1000 ℃, and the NO x Online detection instrument 13 detects NO in flue gas x The concentration is 650mg / Nm 3 , After spraying urea, NO x Online detection instrument 13 detects NO in flue gas x The concentration becomes 200 mg / Nm 3 , The actual denitrification efficiency after urea treatment by the secondary spray gun 5 is 69.2%, and the ammonia leakage detected...

Embodiment 2

[0031] The reducing agent used is ammonia, and the ratio of ammonia to nitrogen is 1.0. The first-stage spray gun 3 is installed at the position of the tail 2 of the cement rotary kiln, and the temperature is 1050℃. The NO x Online detection instrument 13 detects NO in flue gas x The concentration is 1210 mg / Nm 3 , After spraying ammonia water after NO x Online detection instrument 13 detects NO in flue gas x The concentration becomes 320mg / Nm 3 , The actual denitrification efficiency after the first-stage spray gun 3 is sprayed with ammonia is 74%; the second-stage spray gun 5 is placed at the bottom of the decomposition furnace 4 at a temperature of 900~950℃, and the NO x Online detection instrument 13 detects NO in flue gas x The concentration is 750mg / Nm 3 , After spraying ammonia water after NO x Online detection instrument 13 detects NO in flue gas x The concentration becomes 265 mg / Nm 3 , The actual denitration efficiency after spraying urea by the secondary spray gun 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com