Semiconductor optical detector structure

A semiconductor and crystal technology, applied in the field of solar cell structure manufactured at low temperature, can solve problems such as quality limitations of tandem junction cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

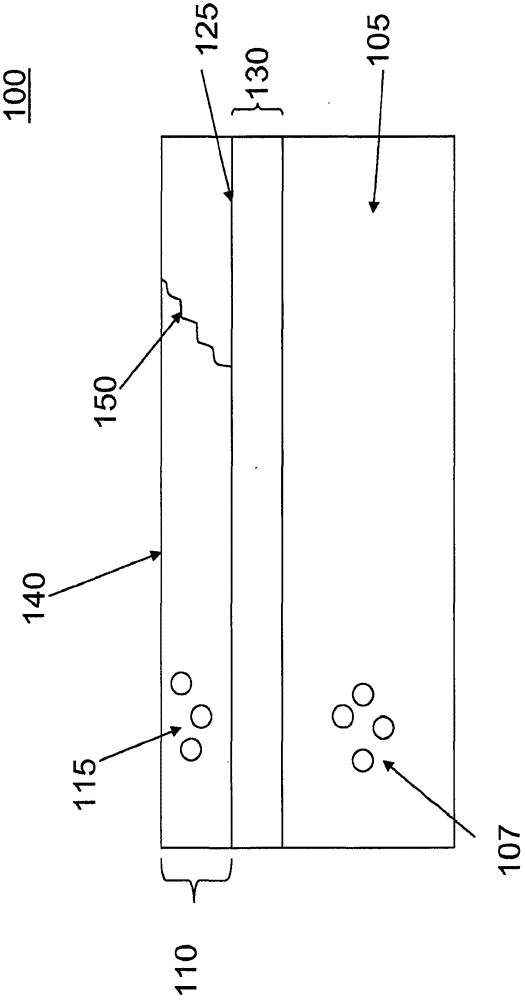

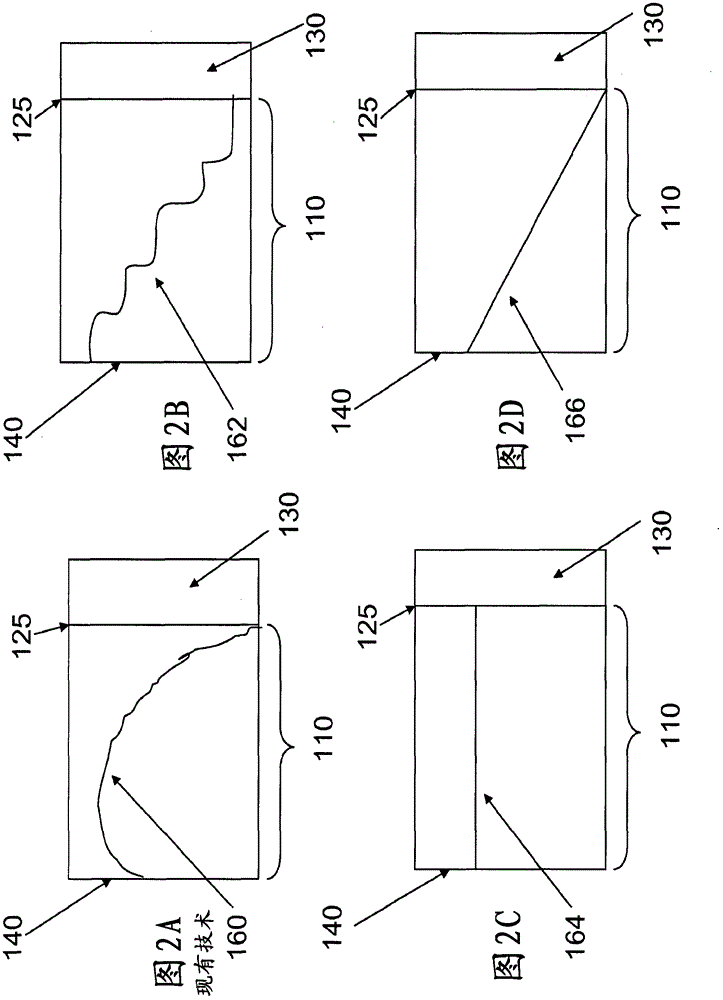

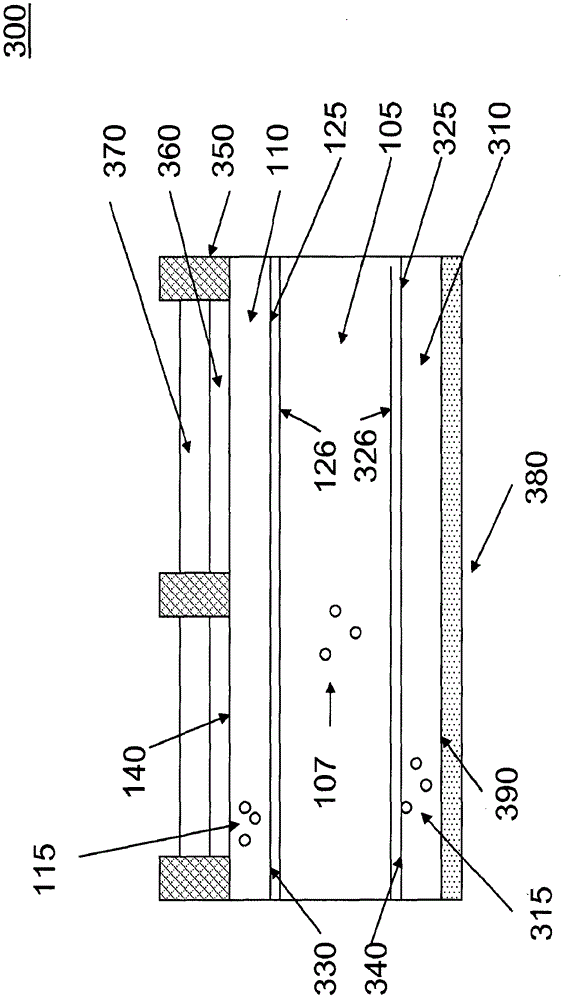

[0039] Various device structures including semiconductor substrates are described. An amorphous semiconductor layer is deposited on the surface of the first substrate and annealed at a temperature sufficient to crystallize the amorphous layer but equal to or less than 700C. In a preferred embodiment, the passivation and anti-reflection coatings are deposited at or below 700C, as are the metal electrodes in contact with the semiconductor surface, resulting in a device capable of detecting electromagnetic radiation. The substrate 105 may comprise a single crystal or polycrystalline semiconductor wafer, or a thin film semiconductor residing on a heterogeneous substrate (material) such as glass, quartz, metal, graphite, plastic, metallurgical grade silicon Or ceramics. In alternative embodiments, the substrate 105 may be silicon, silicon on glass, silicon on sapphire, silicon on quartz, silicon on metal, silicon on graphite, silicon on ceramic, a compound of silicon and germanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com