Roller mill

A technology of roller mills and grinding roads, applied in the field of roller mills, can solve the problems of energy loss and achieve the effects of reducing energy, increasing production, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

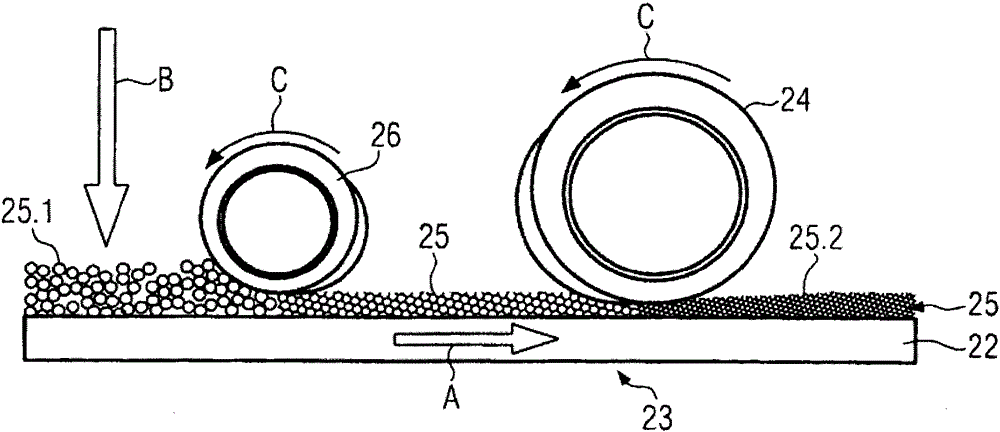

[0029] Figures 1 and 2 illustrate the prior art. FIG. 1 shows the already described principle of operation of the roller pair comprising the grinding roller 24 and the pre-pressing roller 26 .

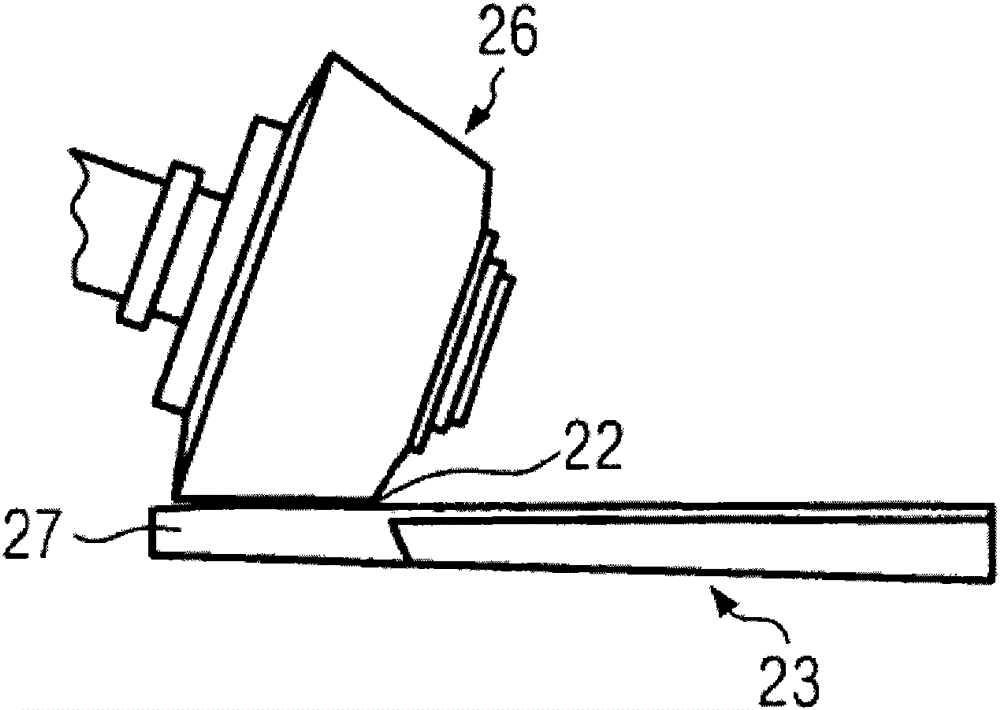

[0030] Figure 2 is a view showing a known arrangement of pre-compression rollers 26 arranged on the outer grinding track edge 27 and thus arranged in running ring with a subsequently arranged grinding roller (not shown) Actually the same running ring.

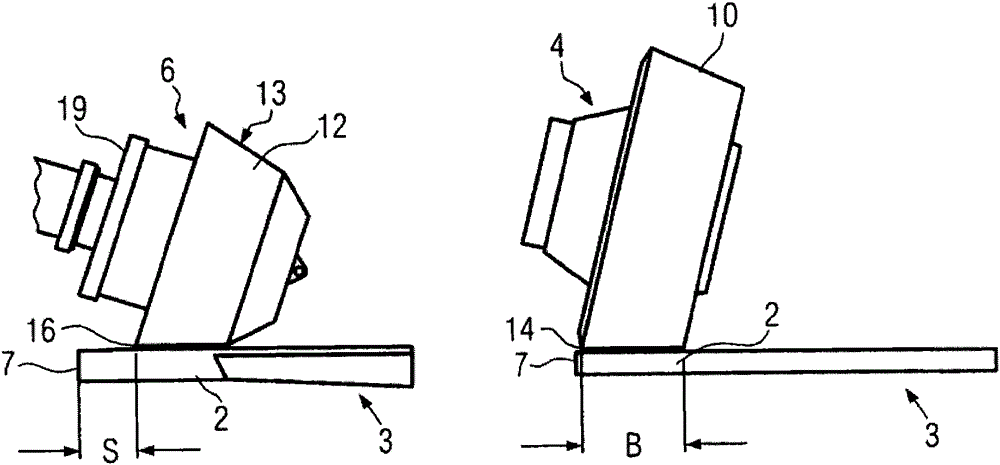

[0031] image 3 The pre-compression roll 6 according to the invention is shown arranged in such a way that it rolls completely over the grinding stock (not shown) which is supplied helically to the distributing grinding roll 4 and compacts it. Grinding material.

[0032] The grinding roll 4 and the pre-pressing roll 6 are conical rolls that roll on the flat grinding track 2 with a parallel grinding gap structure. image 3 A pre-compression roll 6 is shown, which is formed smaller than the grinding roll 4 since it is only used for prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com