Electric connector assembly and line end connector

A wire-end connector and electrical connector technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problem of separation of wire-board end connectors, etc., and achieve stable signal transmission and stable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

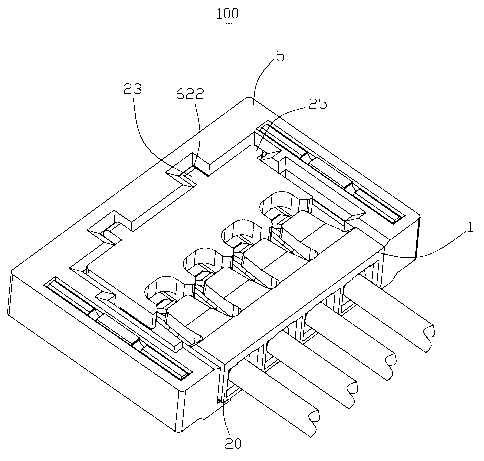

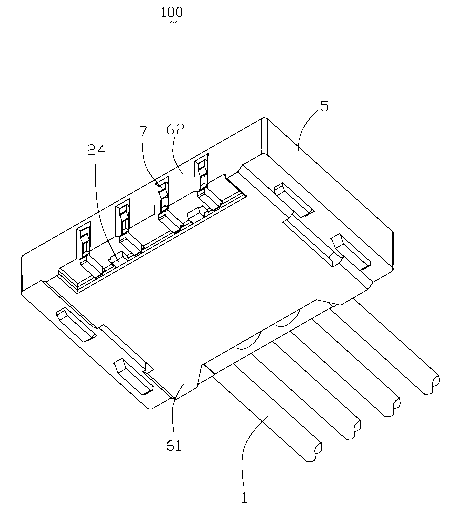

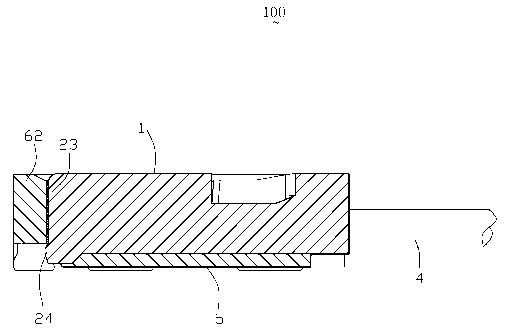

[0022] Please refer to Figure 1 to Figure 6 As shown, the electrical connector assembly 100 of the present invention includes a wire-end connector 1 and a board-end connector 5 that are connected to each other. Wherein the wire end connector 1 and the board end connector 5 are butt connectors of each other. The wire end connector 1 includes a first insulating body 2 , several wire end terminals 3 fixed on the first insulating body 2 and cables 4 connected to the wire end terminals 3 . The board end connector 5 includes a second insulating body 6, a board end terminal 7 fixed on the second insulating body 6 to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com