Shell-and-plate heat exchanger with asymmetric structure and manufacturing method thereof

A plate-shell type, asymmetrical technology, applied in the direction of indirect heat exchangers, heat exchanger types, manufacturing tools, etc., can solve problems such as poor effect and affect system energy efficiency, to reduce cost and weight, and reduce land occupation Dimensions and installation requirements, the effect of convenient cleaning and sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

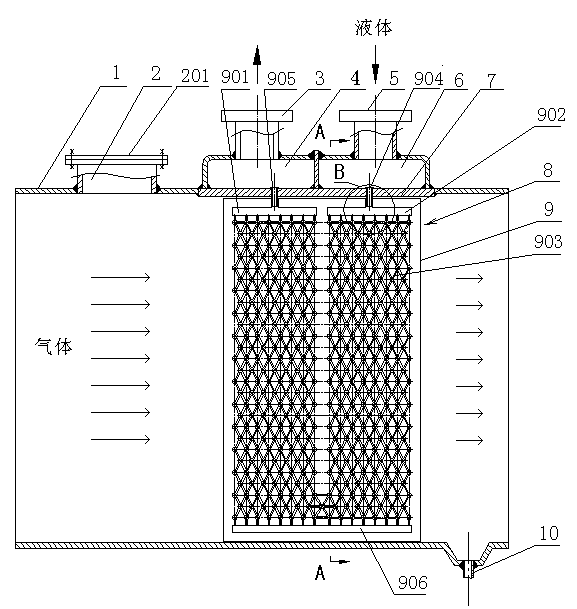

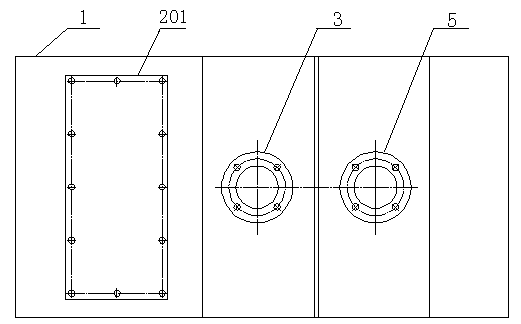

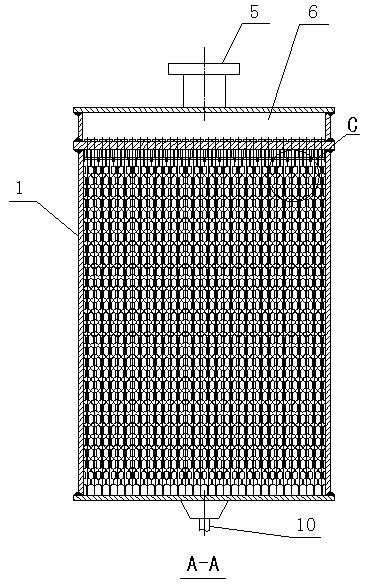

[0025] like figure 1 — Figure 5 As shown, the plate-shell heat exchanger with an asymmetric structure includes a shell side shell 1, a plate tube bundle 8 arranged in the shell side shell 1, and a tube side box 4, 6; the plate tube bundle 8 includes several plate tubes 9, The plate tube 9 is composed of two cold-formed tube pieces 910, 911, and the tube pieces 910, 911 are distributed with concave bosses 907 arranged in a diamond shape and grooves 908 communicating with the bosses 907, wherein the concave The height of the groove 908 is less than the height of the boss 907, and the boss 907 and the groove 908 on the two tube pieces 910, 911 correspond to the liquid flow channel 903 of the plate tube 9; the liquid flow channel 903 in the plate tube 9 is U The shape is divided into a downward flow channel and an upward flow channel; the upper end of the plate tube 9 is provided with a liquid inlet cavity 902 and a liquid outlet cavity 901 communicating with the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com