Axial locking joint of glass reinforced plastic pipeline

A technology of axial locking and fiberglass, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/fitting, mechanical equipment, etc., can solve the problems of leakage, high probability of joint leakage, and affecting the service life of pipelines, etc., to reduce leakage Leakage probability, reduced construction costs and man-hours, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

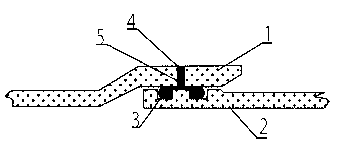

[0012] The fiberglass pipe axial locking joint of the present invention includes a socket 1 and a socket 2, and two O-shaped sealing rings 3 are arranged between the socket 1 and the socket 2 . The corresponding position of the socket 1 (that is, between the two O-rings 3) is provided with a glue hole 4. The cross section of the glue hole 4 is circular or rectangular, and the side of the socket is rounded. The inner wall of the socket of the glue hole 4 The side is a circular arc transition. Resin material is poured into the glue filling hole 4 to form a locking sealing ring 5 .

[0013] The resin is an unsaturated polyester resin or a vinyl series resin added with quartz powder, and the bonding strength between the resin and the socket can withstand the axial tension of the FRP pipe and play an anti-seepage role.

[0014] In order to realize that the glass steel pipe socket with locking device can fully bear the axial stress, the socket and socket section of the pipe are str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com