Micro solenoid valve with low power consumption

A solenoid valve, low power consumption technology, applied in the field of solenoid valves, can solve the problems of small medium flow, high working temperature, complex structure, etc., and achieve the effect of increasing medium flow, reducing power consumption, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

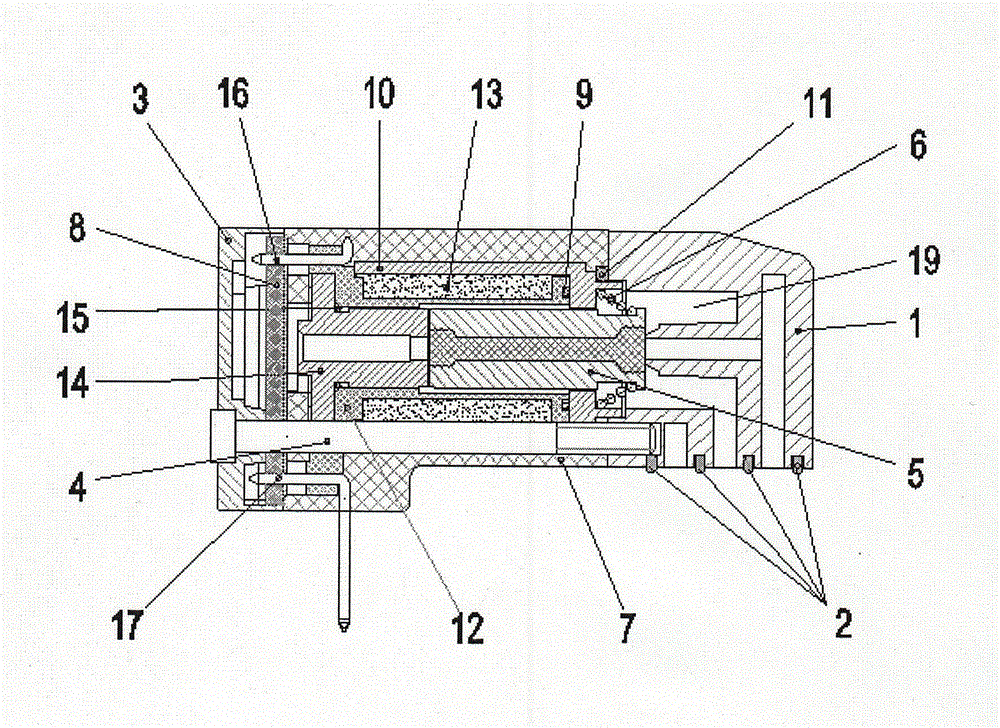

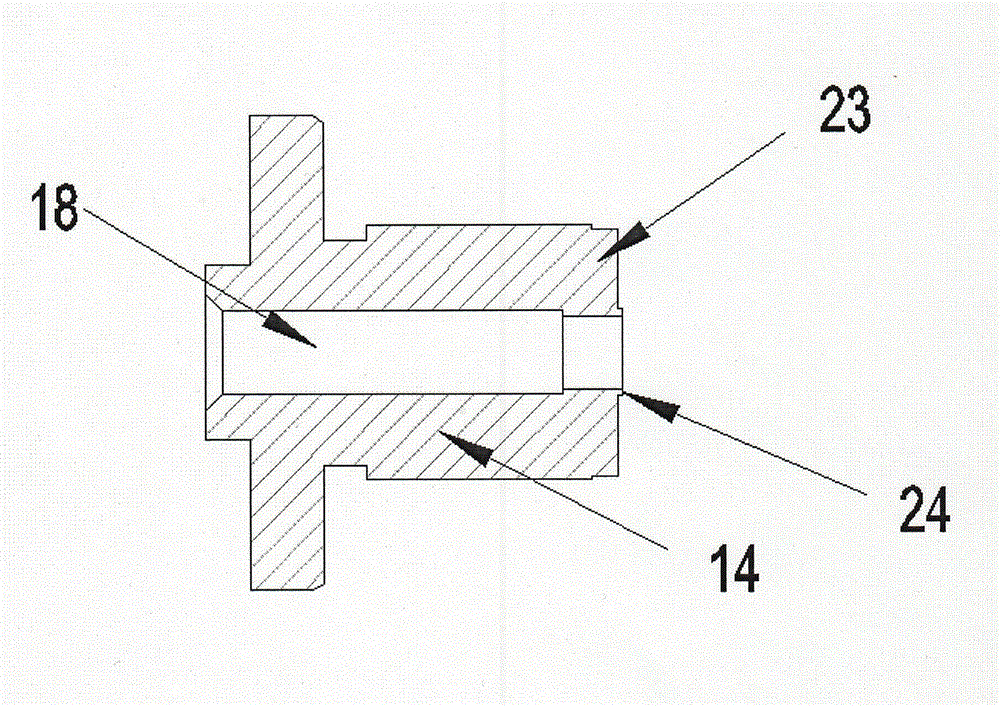

[0014] Embodiment 1: as figure 1 As shown, the low-power miniature solenoid valve includes valve body 1, valve body sealing ring 2, end cover 3, fastening screw 4, moving iron core 5, moving iron core spring 6 and electromagnetic coil assembly 7, electromagnetic coil assembly 7 includes circuit board 8, coil O-ring 9, fixed sleeve 10, fixed sleeve O-ring 11, skeleton 12, enameled wire 13, static iron core 14, static iron core O-ring 15, connecting pin 16 and pin 17. The circuit board 8 adopts a pulse circuit control chip. One end of the pulse circuit control chip circuit board 8 is connected to the enameled wire 13 through the connection pin 16, and the other end is connected to the external power supply through the pin 17, such as figure 2 As shown, an exhaust hole 18 is arranged at the center of the static iron core 14, and one end of the exhaust hole 18 is connected with the electromagnetic valve cavity 19, and the other end is connected with the atmosphere, as image 3 A...

Embodiment 2

[0016] Embodiment 2: The outer diameter of the static iron core 14 is 8.4 mm, and the end of the small head 23 of the static iron core is provided with a sealing boss 24 of ф1.54 and 0.5 mm in height, and the rest are the same as in the embodiment 1.

Embodiment 3

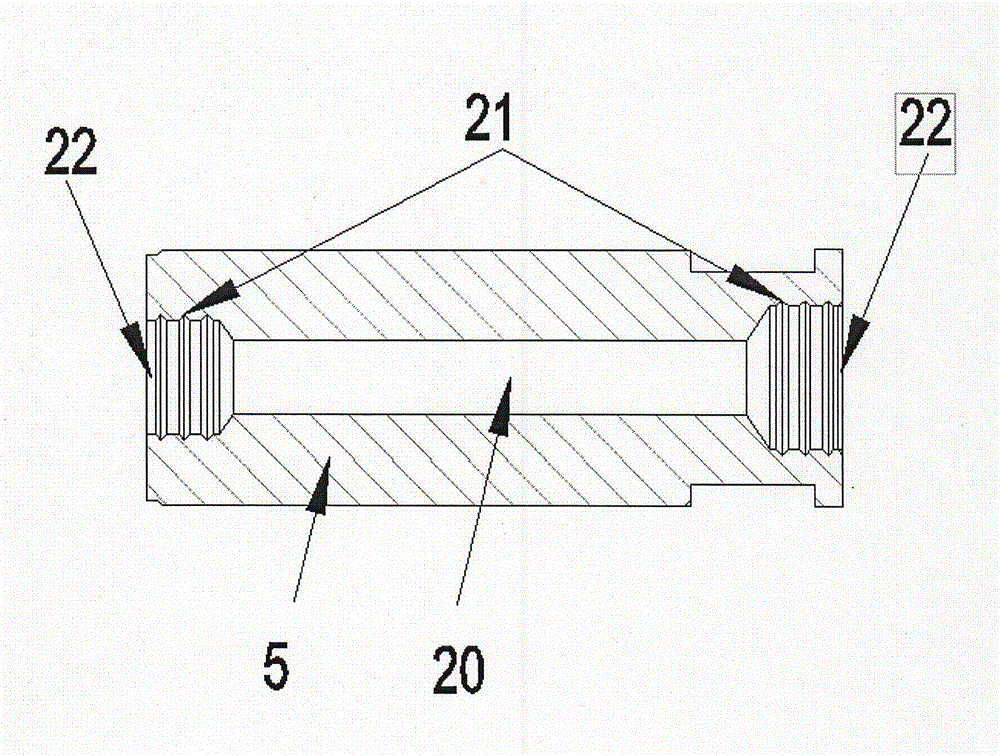

[0017] Embodiment 3: The outer diameter of the moving iron core 5 is 4.5mm, and there is a through hole 20 inside. The two ends of the through hole 20 are respectively connected to the large holes 22 with ф2.5 and ф2 and five anti-skid grooves 21 inside, and the rest are the same as in Embodiment 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com