Fabricated grilling anti-invert method for treating pucking

An anti-bottom arch and assembled technology, which is applied in the direction of earthwork drilling, installation of bolts, mining equipment, etc., can solve the problems of poor bottom drum control, insufficient rigidity, and difficulty in drilling downwards, and achieve the time required for the surrounding rock to be exposed Short, simple structure rules, fast and effective reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

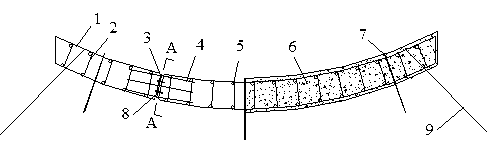

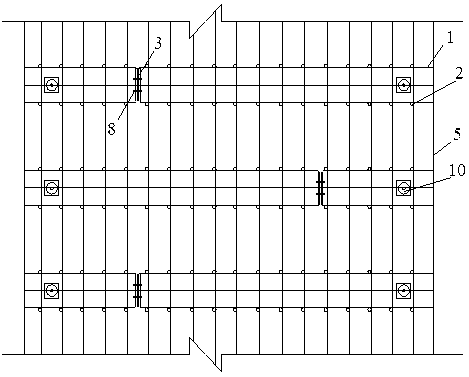

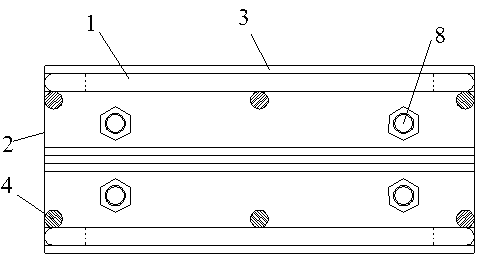

[0016] The method for treating the bottom drum of the assembled grid anti-bottom arch of the present invention adopts the method of laying the grid anti-bottom arch at intervals on the bottom plate of the roadway, and performs permanent support on the bottom plate of the roadway by installing rigidly connected anchor rods, pouring concrete, and filling grouting after the wall . The components used include main reinforcement 1, stirrup 2, angle steel 3, reinforcement 4, connecting reinforcement 5, grouting pipe 7, bolt 8, rigid anchor rod 9, anchor rod tray and nut 10, and grouting pipe 7 is with internal Threaded steel pipe. The specific implementation process is as follows:

[0017] a. After the roadway is excavated, the grid anti-bottom arches are laid at intervals on the roadway floor. According to the width design of the roadway, each grid anti-bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com