Special alloy having functions of inhibiting separation and agglomeration of wax in liquid

A kind of alloy and special technology, which is applied in the field of metal functional materials, can solve the problems of chemical substance discharge, pollute the environment, affect the production efficiency of crude oil, etc., achieve the effect of reducing the amount of precipitation, reducing the rate of precipitation, and avoiding discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Demonstration of the function of inhibiting the precipitation of paraffin in diesel oil, the weight percentage of the alloy composition is shown in Table 1:

[0024] Table 1 Alloy composition weight percentage (%)

[0025] Ni Cu Zn sn Pb co Gd Ti B 23.3 54.7 15.1 1.3 3.1 1.4 0.5 0.5 0.10

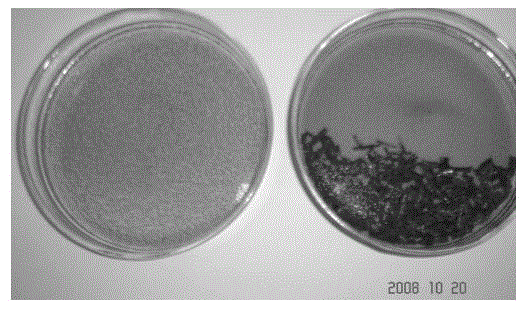

[0026] After melting the alloy in a vacuum induction furnace under the protection of Ar gas, the alloy powder was taken. Put 0# diesel oil and paraffin in two petri dishes, and put alloy particles in one of them. Then put them into a constant temperature box at 60°C until the paraffin is completely dissolved, take it out and observe the precipitation of paraffin with temperature. Visible: Petri dish without alloy ( figure 1 In the petri dish on the left in the middle), the paraffin wax precipitates faster, the amount is large, and the precipitates are relatively coarse, while in the petri dish with alloys, the paraffin wax precipitates late...

Embodiment 2

[0029] Demonstration of the function of inhibiting the precipitation of paraffin in water, the weight percentage of the alloy composition is shown in Table 2:

[0030] Table 2 Alloy composition weight percentage (%)

[0031] Ni Cu Zn sn Pb co La+Ce 18.5 65.7 7.8 3.8 1.5 2.0 0.7

[0032] After melting the alloy in a vacuum induction furnace under the protection of Ar gas, the alloy powder was taken. Put water and paraffin in two Petri dishes, and put alloy particles in one of them. Then put them into a thermostat at 100°C until the paraffin is completely dissolved, take it out and observe the precipitation of paraffin with temperature. Visible: Petri dish without alloy ( figure 2 In the petri dish on the left side of the center), the paraffin wax precipitates very quickly and forms a film, and the amount is large, while in the petri dish with alloys, the paraffin wax precipitates later, with a small amount and is more dispersed (see fig...

Embodiment 3

[0035] The effect of oilfield downhole wax-proof tools made of special wax-proof alloys on the oil well flushing cycle, the weight percentage of alloy composition is shown in Table 3:

[0036] Table 3 Alloy composition weight percentage (%)

[0037] Ni Cu Zn sn Pb co La+Nd Ti B 14.6 45.9 27.0 5.6 3.5 1.4 1.0 0.9 0.10

[0038] The vacuum induction furnace is used to melt the alloy in a vacuum state, and the Ar gas is filled before adding the low melting point metal. After pouring, it is made into a porous pipe, which is installed 10 meters below the oil well pump. The depth of the oil well is 1900 meters. Using electric heating to remove wax, the wax removal cycle is 40 days, and the wax removal cycle is extended to 254 days after using alloy tools, and the wax prevention effect is remarkable.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com