Method for producing rhamnolipid by virtue of fermentation and separation of pseudomonas aeruginosa

A technology for Pseudomonas aeruginosa and rhamnolipid, which is applied in the field of separation and production of rhamnolipid and fermentation of Pseudomonas aeruginosa, and can solve the problem that there is no public sale of pure rhamnolipid glycolipid and restrictions on rhamnolipid Commercial production process, high production costs and other problems, to achieve the effect of easy control of equipment, lower production costs, and reduce foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

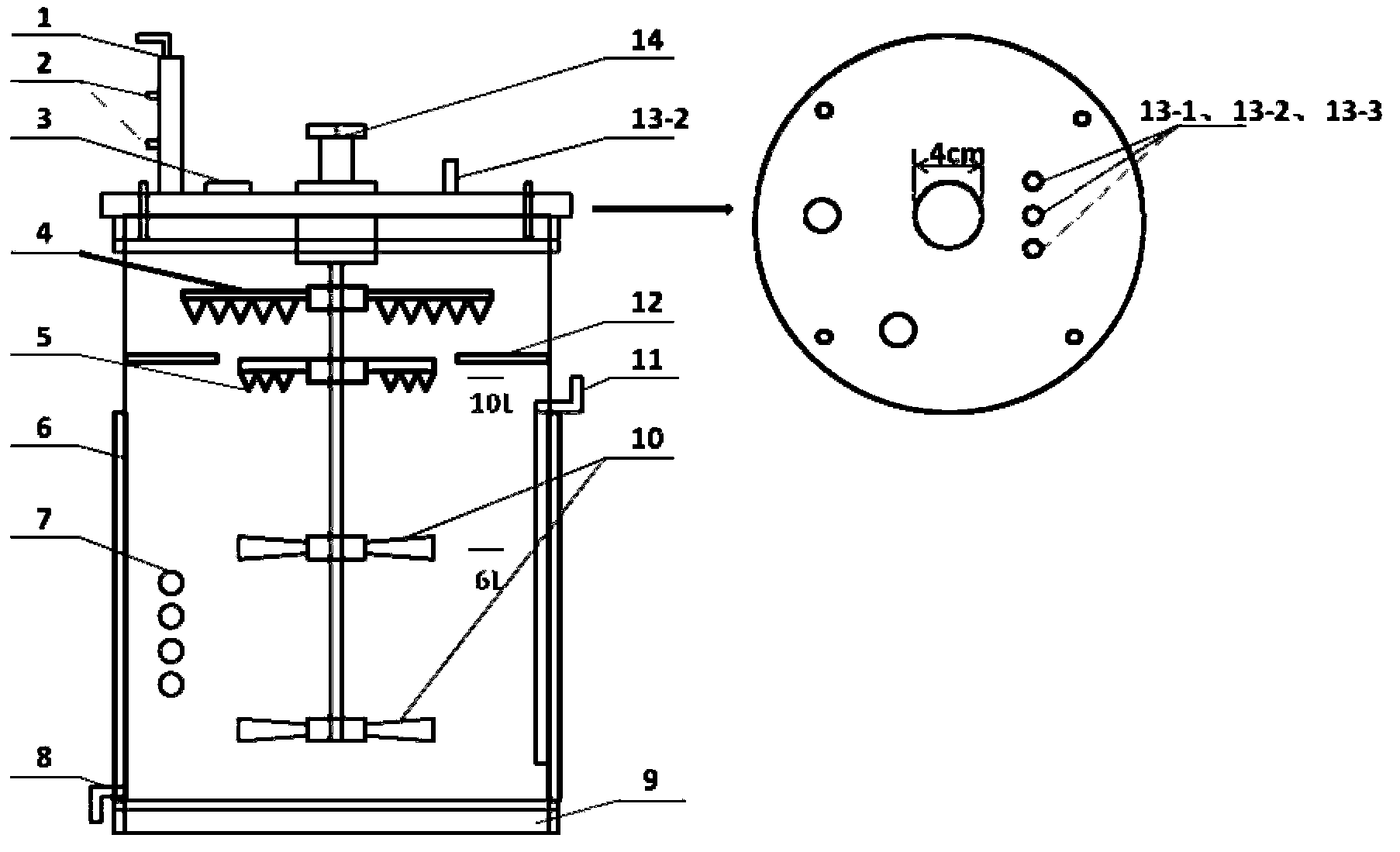

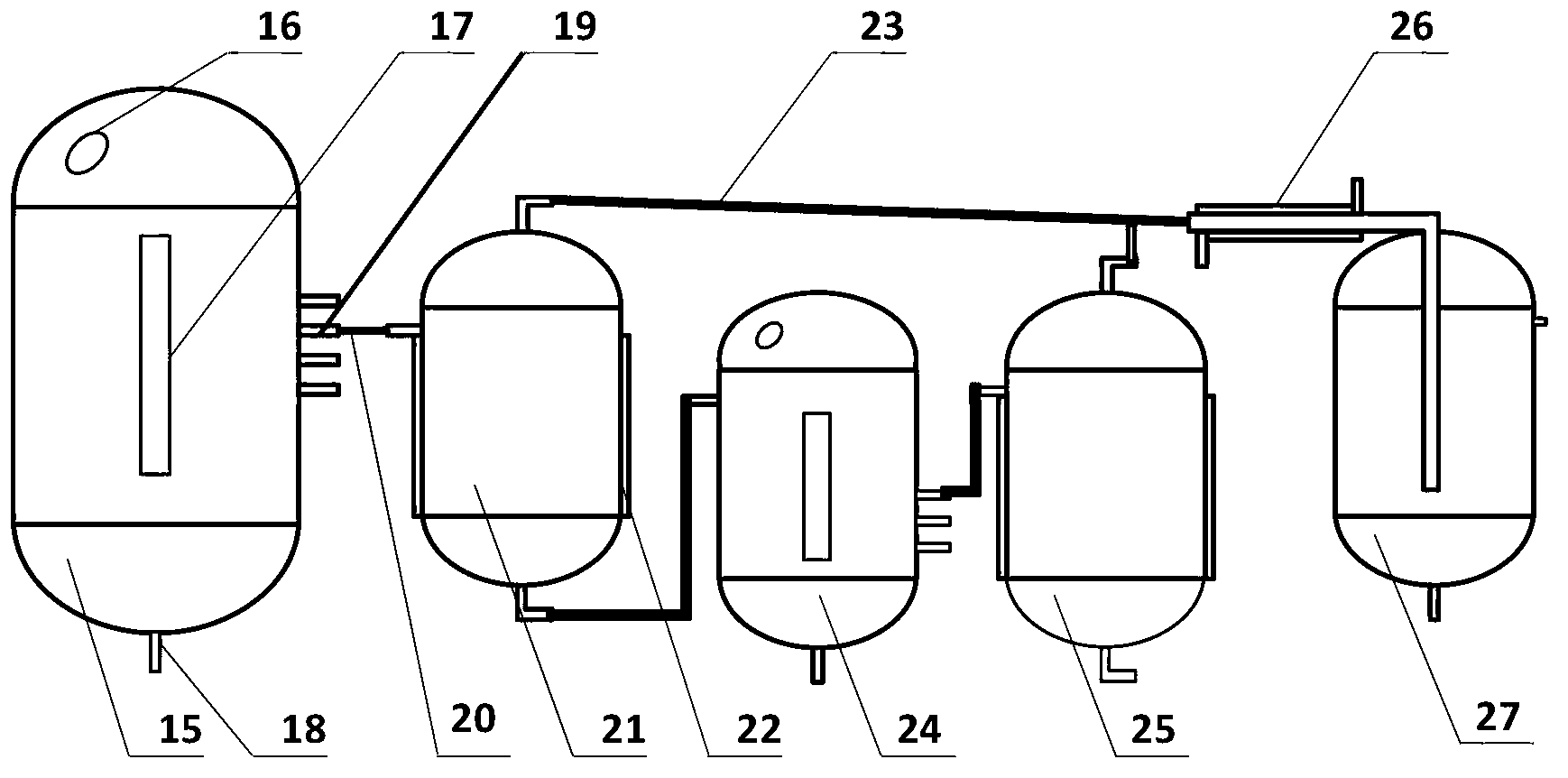

[0031] see figure 1 , a method for Pseudomonas aeruginosa fermentation, separation and production of rhamnolipids, comprising the following steps:

[0032] 1) The Pseudomonas aeruginosa strains were transferred into shake flasks for expansion culture by the slant inoculation method to obtain the Pseudomonas aeruginosa seed liquid.

[0033] 2) First add the sterilized fermentation medium into the fermenter, then put the Pseudomonas aeruginosa seed liquid into the fermenter according to the inoculum amount of 8%, and add 1‰ of foam into the medium before inoculating the seed liquid The concentration of each component in the above fermentation medium is (g / L): soybean oil 40; KH2PO4 3; K2HPO4 6; NaNO3 2; NaCl 0.5; KCl0.5; MgSO4·7H2O 0.1; Element solution 2mL / L; pH of trace element solution: 7.0, concentration of each solute in trace element solution (g / L): FeSO4·7H2O 12; ZnSO4·7H2O 3.0; CoSO4·7H2O 1.0; MnSO4·2H2O 3.0.

[0034] In this embodiment, the above fermenter is a defoam...

Embodiment 2

[0047] The difference with embodiment 1 is:

[0048] 1. In step 2), the inoculation amount of Pseudomonas aeruginosa seed solution is 12%; 5‰ of foam enemy is added in the medium; the concentration of each component in the fermentation medium is (g / L): large Soybean oil 120; KH2PO4 7; K2HPO4 10; NaNO3 4; NaCl 2; KCl 2; MgSO4 7H2O 1; anhydrous CaCl2 0.5; trace element solution 10mL / L; The concentration is (g / L): FeSO4·7H2O 12; ZnSO4·7H2O 3.0; CoSO4·7H2O 1.0; MnSO4·2H2O 3.0.

[0049] Two, in step 3), the pH of the pasty fermented liquid is adjusted to 3; the concentration of adding ethyl acetate for the first extraction is 60%, and the concentration of adding ethyl acetate for extraction again is 60%; obtained at the bottom of distillation tank 25 The paste rhamnolipid purity is 90%.

[0050] 3. In step 4), after drying the paste rhamnolipid, the purity of the obtained rhamnolipid is 99%.

[0051] Except that the above parameters are different from those in Example 1, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com