Cation coating agent for water-base drilling fluid and preparation method thereof

A water-based drilling fluid and cation technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unstable performance, increased mud screen loss, and increased system viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

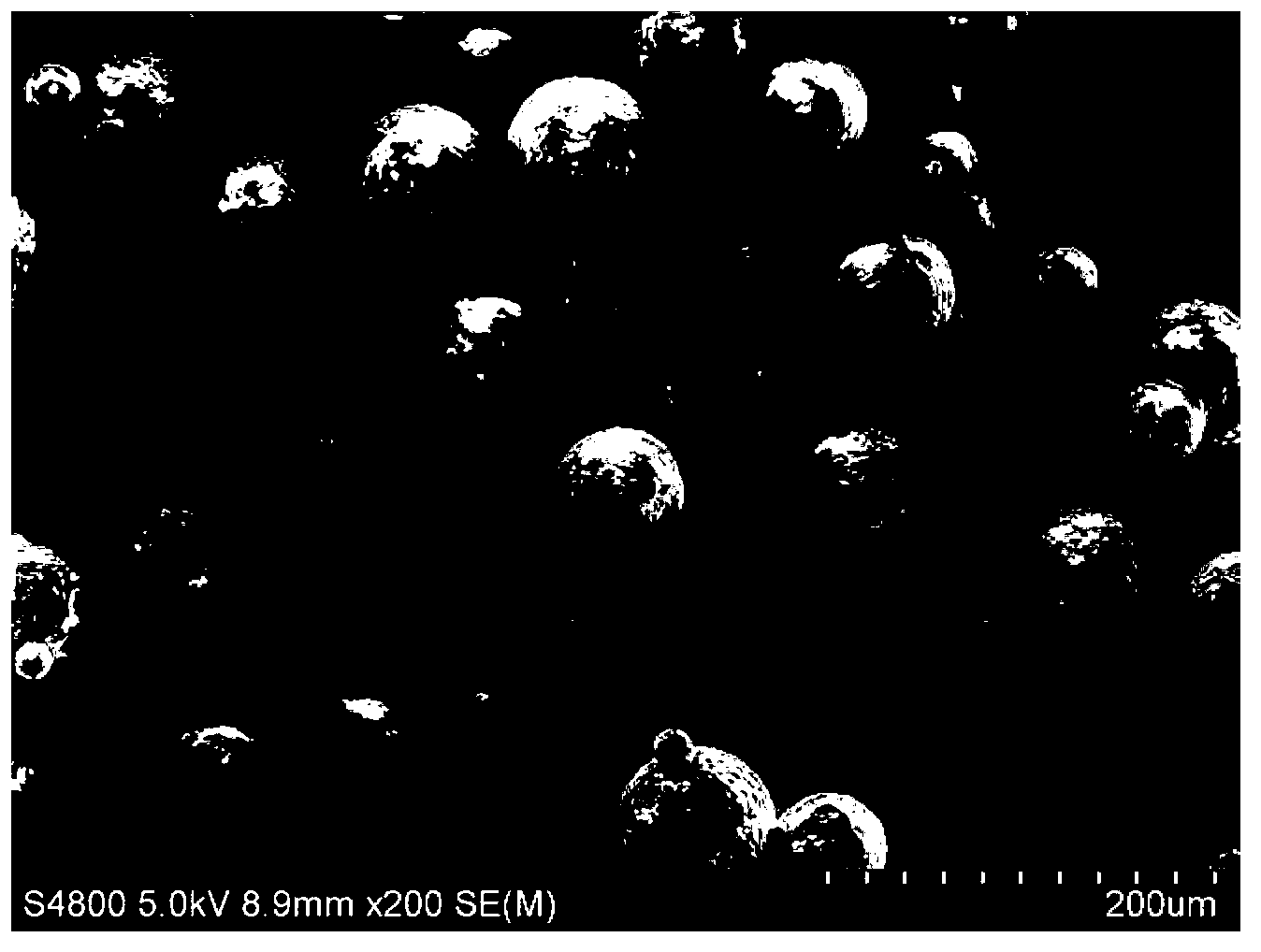

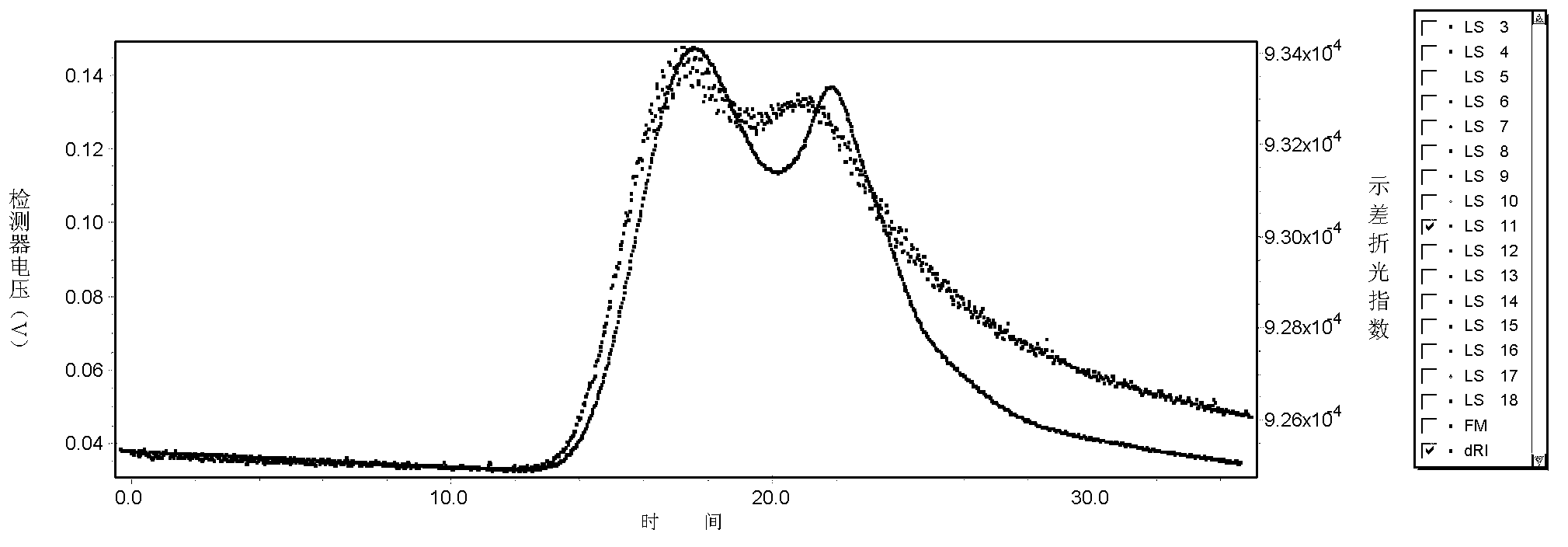

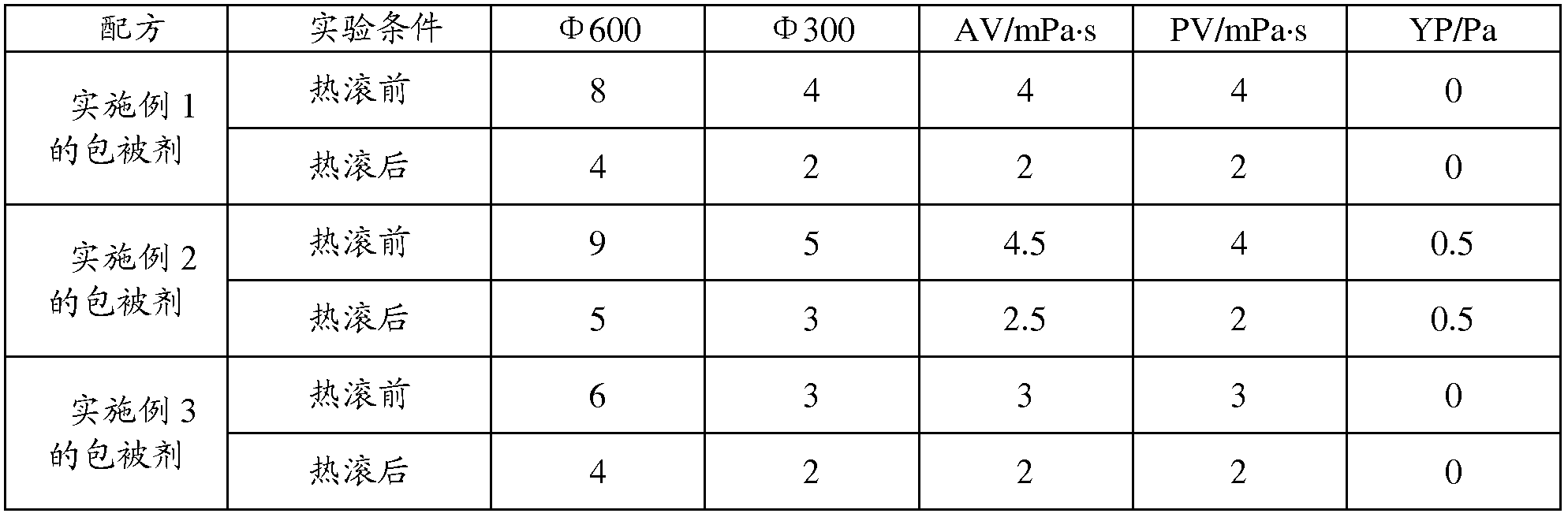

Embodiment 1

[0027] Add 600mL of cyclohexane and 2.8g of sorbitan monostearate into a 1000mL four-neck flask, heat to 40°C and stir to dissolve the sorbitan monostearate to obtain an oil phase, and then cool for use. Add 60g of N,N-dimethylacrylamide, 18.2g of diallyldimethylammonium chloride aqueous solution and 40mg of dodecyl mercaptan into a beaker, and dissolve them completely with 50ml of distilled water to obtain monomer solution. Slowly drop the prepared monomer solution into the four-neck flask, blow nitrogen gas for about 30 minutes, and start heating to raise the temperature. When the temperature rose to 55°C, 840 mg of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of the temperature rise, the temperature was controlled between 65-70° C. to continue the reaction for one hour. After the reaction is completed, start azeotropic water removal, turn on the circulating water vacuum pump, control the vacuum degree (vacuum degree 0.03M...

Embodiment 2

[0029] Add 600mL of cyclohexane and 2.8g of sorbitan monostearate into a 1000mL four-neck flask, heat to 40°C and stir to dissolve the sorbitan monostearate to obtain an oil phase, and then cool for use. Add 60g of N,N-dimethylacrylamide, 20g of methacryloxyethyltrimethylammonium chloride and 45mg of dodecylmercaptan into the beaker, and dissolve them completely with 50ml of distilled water, namely Monomer solution was obtained. Slowly drop the prepared monomer solution into the four-neck flask, blow nitrogen gas for about 30 minutes, and start heating to raise the temperature. When the temperature rose to 55°C, 840 mg of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of the temperature rise, the temperature was controlled between 65-70° C. to continue the reaction for one hour. After the reaction is completed, start azeotropic water removal, turn on the circulating water vacuum pump, control the vacuum degree (vacuum degree 0...

Embodiment 3

[0031]Add 600mL of cyclohexane and 2.8g of sorbitan monostearate into a 1000mL four-neck flask, heat to 40°C and stir to dissolve the sorbitan monostearate to obtain an oil phase, and then cool for use. Add 60g of N,N-dimethylacrylamide, 18g of acryloyloxyethyltrimethylammonium chloride and 50mg of dodecylmercaptan into a beaker, and dissolve them completely with 50ml of distilled water to obtain a single body solution. Slowly drop the prepared monomer solution into the four-neck flask, blow nitrogen gas for about 30 minutes, and start heating to raise the temperature. When the temperature rose to 55°C, 840 mg of ammonium persulfate solution was added. After a while, the reaction self-heated. After the end of the temperature rise, the temperature was controlled between 65-70° C. to continue the reaction for one hour. After the reaction is completed, start azeotropic water removal, turn on the circulating water vacuum pump, control the vacuum degree (vacuum degree 0.03MPa, 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com