High anti-washing and anti-contamination type outer wall acrylic emulsion and preparation method thereof

An acrylic emulsion, scrub-resistant technology, applied in anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of unsatisfactory effects, unsatisfactory scrubbing and stain resistance, etc. , to achieve significant effect, low surface free energy, and improved stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0029] The preparation method of embodiment 1~3 acrylic acid emulsion

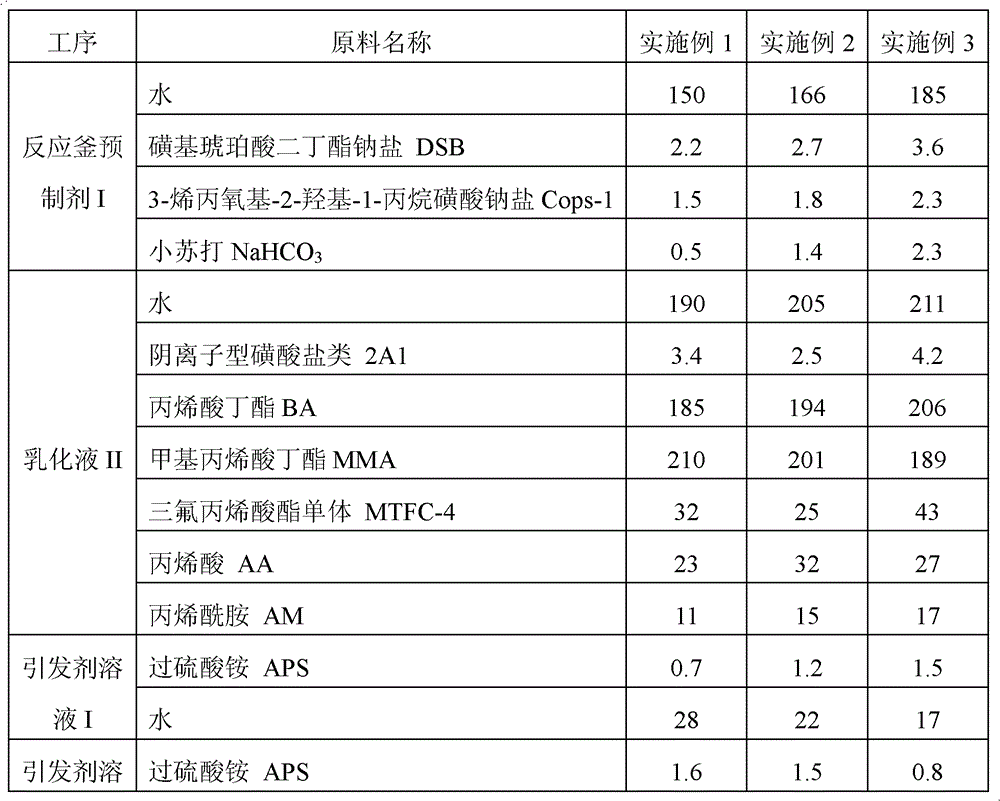

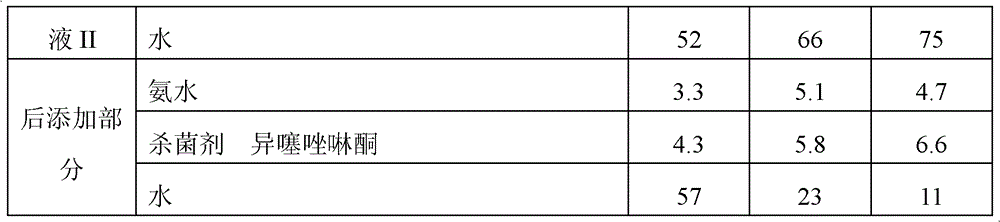

[0030] A high scrub resistance and anti-contamination type exterior wall acrylic emulsion, the parts by weight of each raw material of its formula is shown in Table 1.

[0031] Table 1 list of raw materials

[0032]

[0033]

[0034] According to Table 1, the reaction kettle pre-formulation I, the emulsion II, the initiator solution I, the initiator solution II, and the post-addition part were prepared respectively.

[0035] (2) Response

[0036] (1) Add the material in the reactor I to the kettle, start to heat up to 80-85°C, and stop heating;

[0037] (2) Add the materials in the emulsion II into the emulsification tank in a high-speed dispersion state, and stir for 30-40 minutes.

[0038] (3) Prepare initiator I and initiator solution II in advance, add initiator solution I when the temperature of the reaction kettle reaches 80-85°C, then start to add emulsion II and initiator solution II dropw...

Embodiment 4

[0042] The performance of embodiment 4 acrylic emulsion

[0043] Use the emulsion of a certain company on the market and the acrylic emulsion prepared in Examples 1 to 3, and use the same amount to make exterior wall latex paint, and then test the performance. Determination of scrub resistance: refer to the GB / T9266-1988 standard. Determination of stain resistance: refer to GB / T9780-1988 standard. The test results are shown in Table 2.

[0044] Table 2 Properties of Acrylic Emulsion

[0045] Test items

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com