Automatic cutting machine

A cutting machine and automatic technology, applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve problems such as unfavorable work, large difference, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

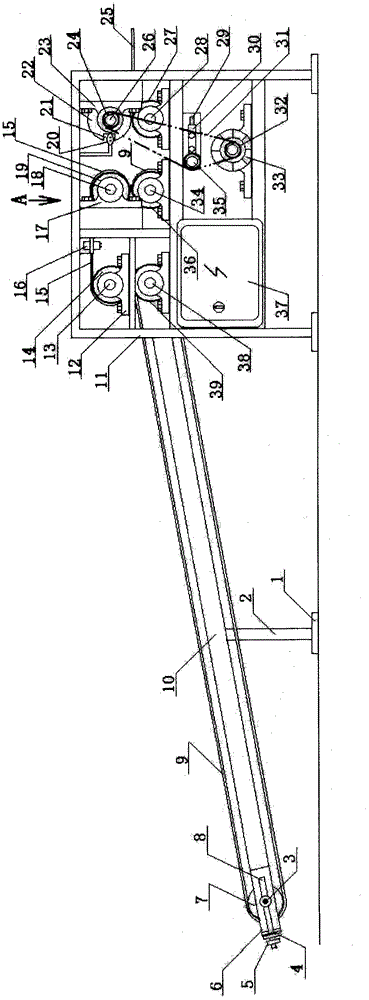

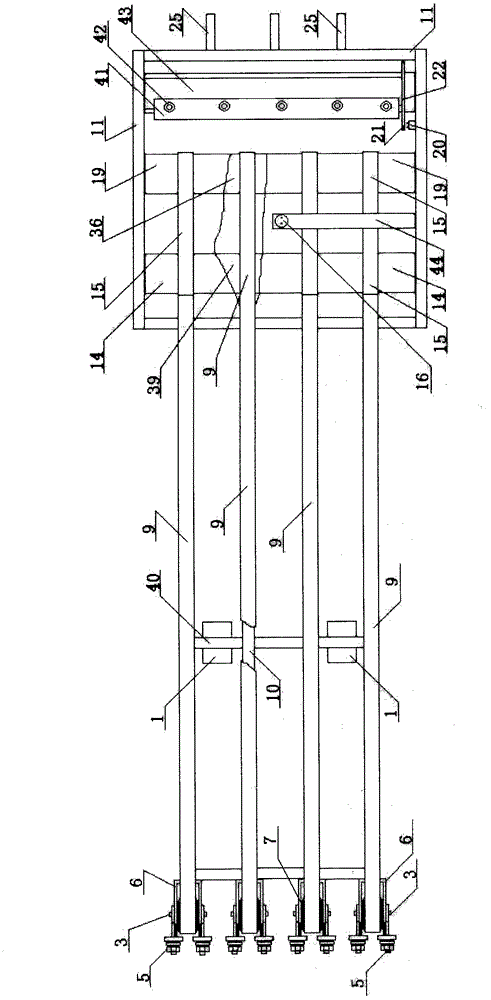

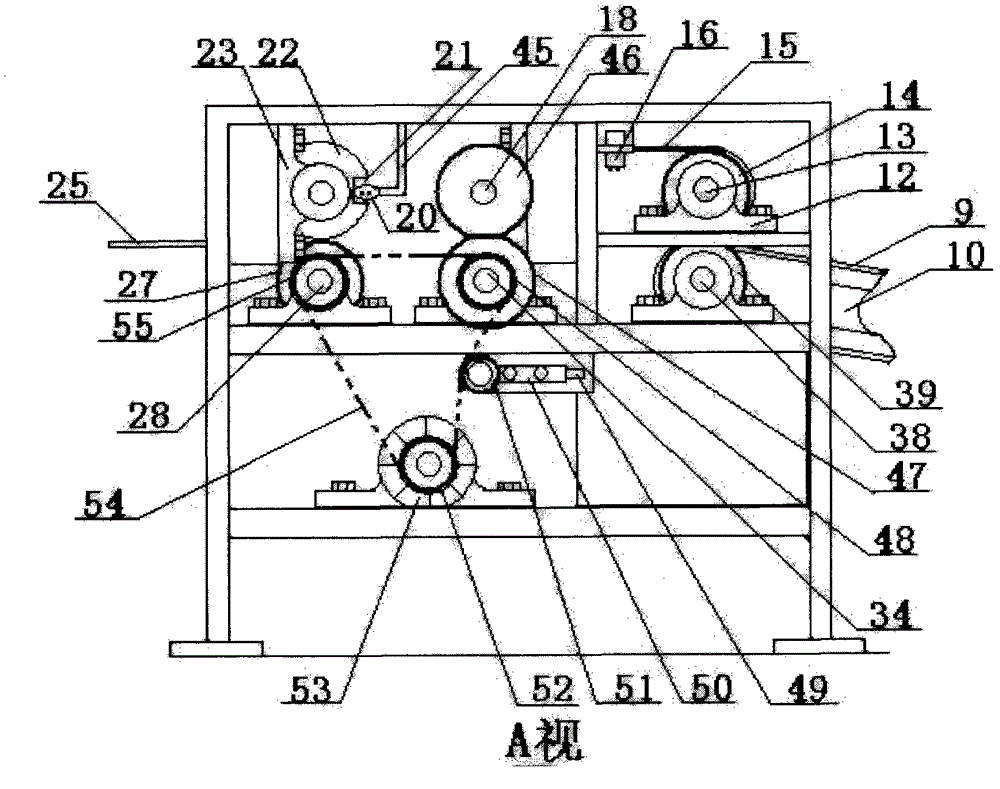

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

[0019] figure 1 Shown is a front view structural schematic diagram of the present invention. It can be seen from the figure that the continuous log veneer output by the rotary cutter is transported to the frame 11 through the conveyor belt 9 on the conveyor frame, wherein the conveyor frame is mainly composed of the conveyor frame foot 1, the conveyor frame vertical rod 2, and the conveyor belt adjustment frame 6 , Conveying frame main rod 10 and conveying frame cross bar 40 constitute. In order to further understand the structural combination of the present invention figure 2 show Figure 1 look up, figure 2 yes figure 1 Schematic diagram of the top view structure. From figure 2 In the partial cross-section of the conveyor belt 9, it can be seen that the conveyor frame cross bar 40 is fixedly connected with the conveyor frame vertical bar 2 and the conveyor fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com