Method for detecting initial position of planar motor

A planar motor and initial position technology, which is applied in the estimation/correction of motor parameters, electromechanical devices, control generators, etc., can solve the problems of structural design complexity and increased costs, and achieve reduced detection costs, precise motion positioning, Effect of Simplified Probing Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

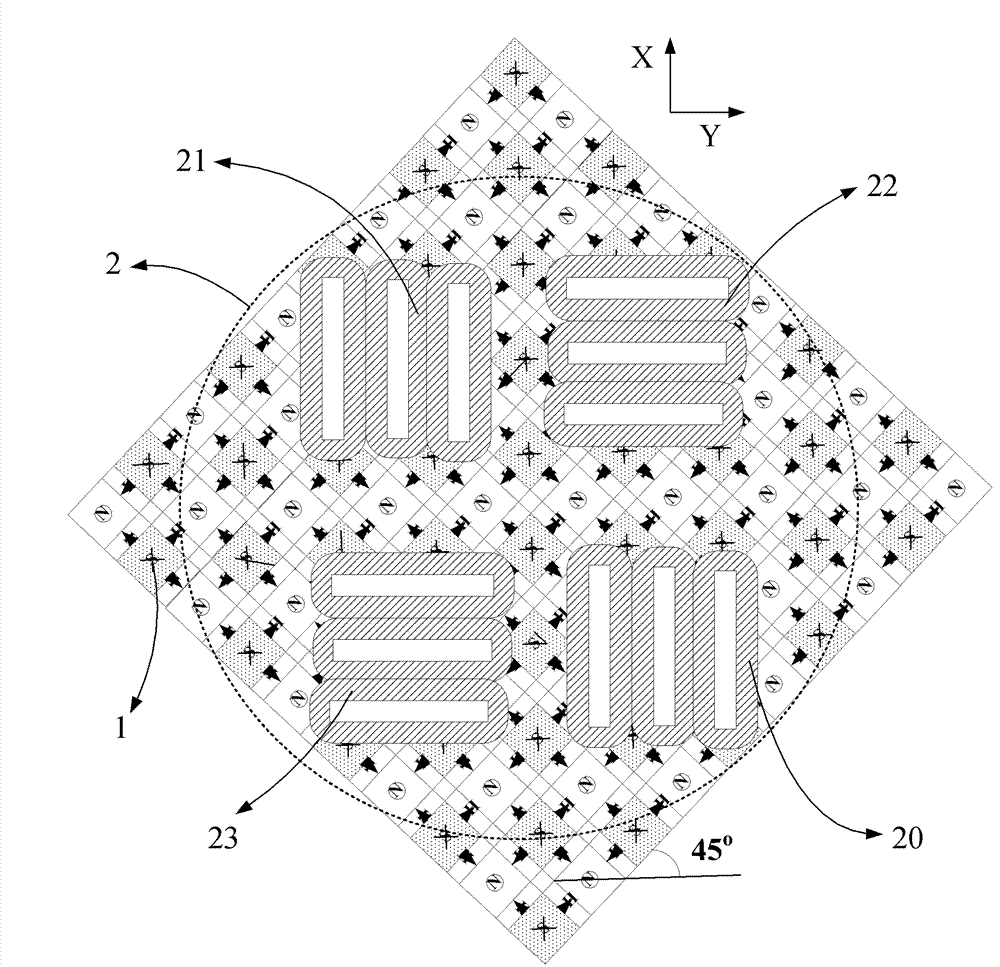

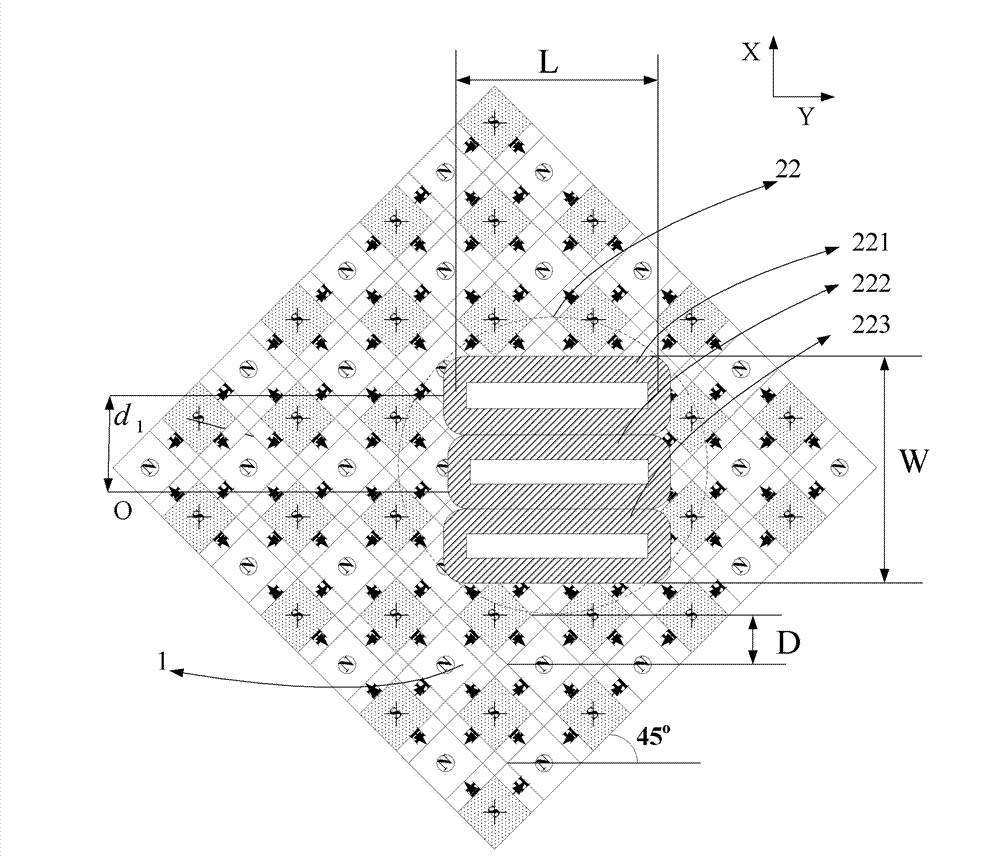

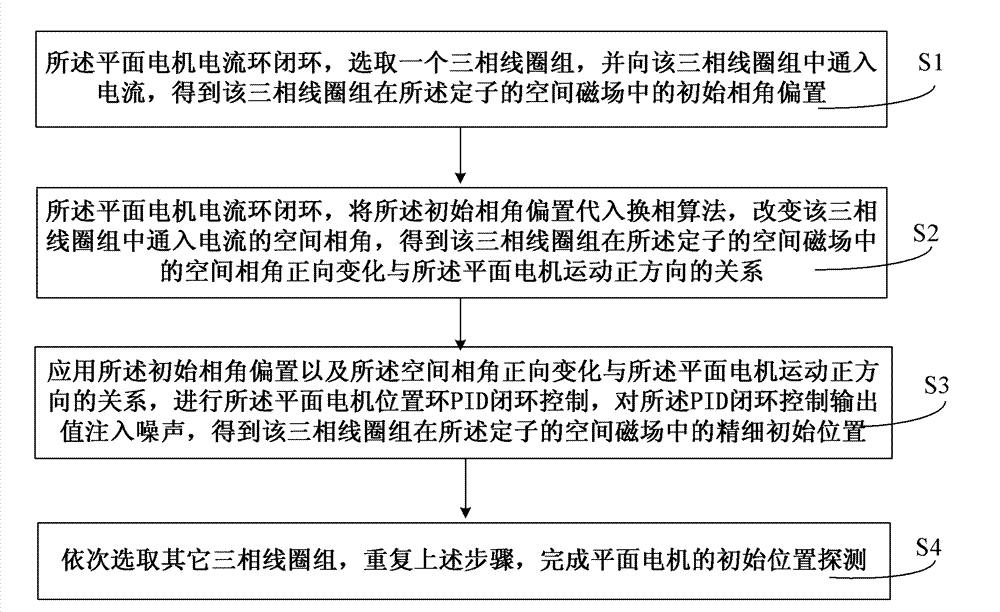

[0038] The method for detecting the initial position of the planar motor proposed by the present invention will be further described in detail below with reference to the drawings and specific embodiments. It should be noted that, in the following description, the X direction is the first horizontal direction, the Y direction is the second horizontal direction, and the Z direction is the vertical direction perpendicular to the first direction and the second direction.

[0039] The invention provides a method for detecting the initial position of a planar motor. The planar motor used is an air-floating coil type planar motor or a moving magnet type air-floating planar motor, which includes a stator, a mover and a position measurement sensor. The mover includes four three Phase coil group.

[0040] Such as Figure 1A and Figure 1B , the stator 1 of the planar motor is a segmented Hall permanent magnet array, and its spatial magnetic field distribution characteristics are that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com