Straightly-inserted terminal with low inserting force and high extracting force

A technology of in-line terminals and low insertion force, which is applied in the field of terminal blocks and in-line terminals, can solve the problems of stable connection with small insertion resistance, and achieve the effects of easy insertion, stable connection, and large operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

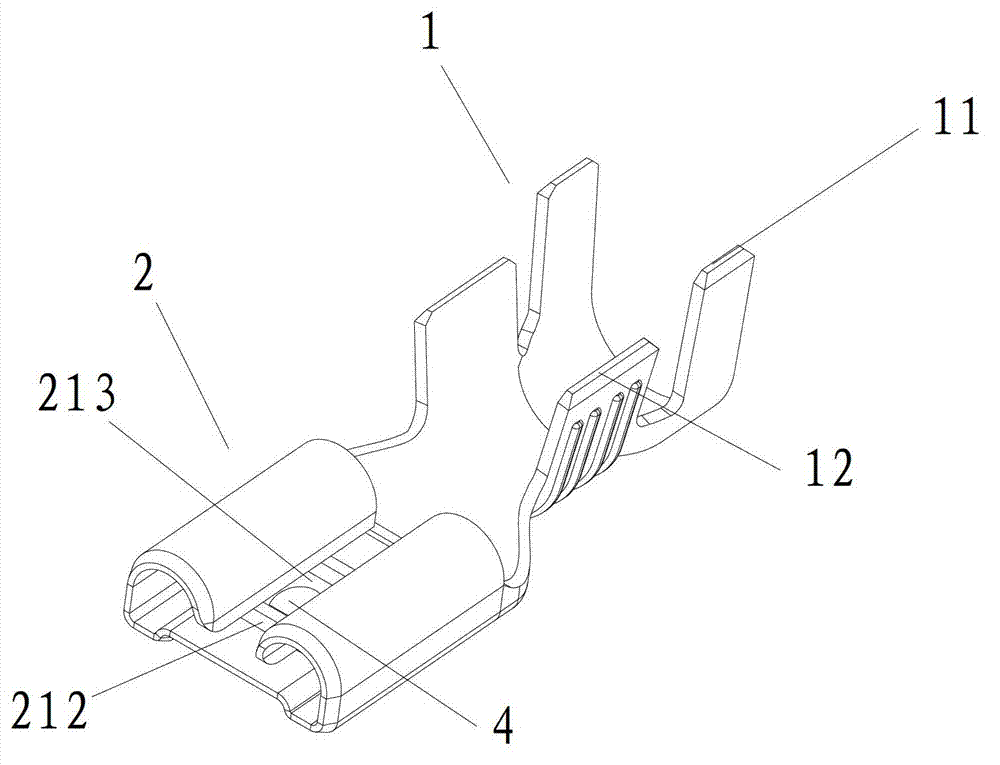

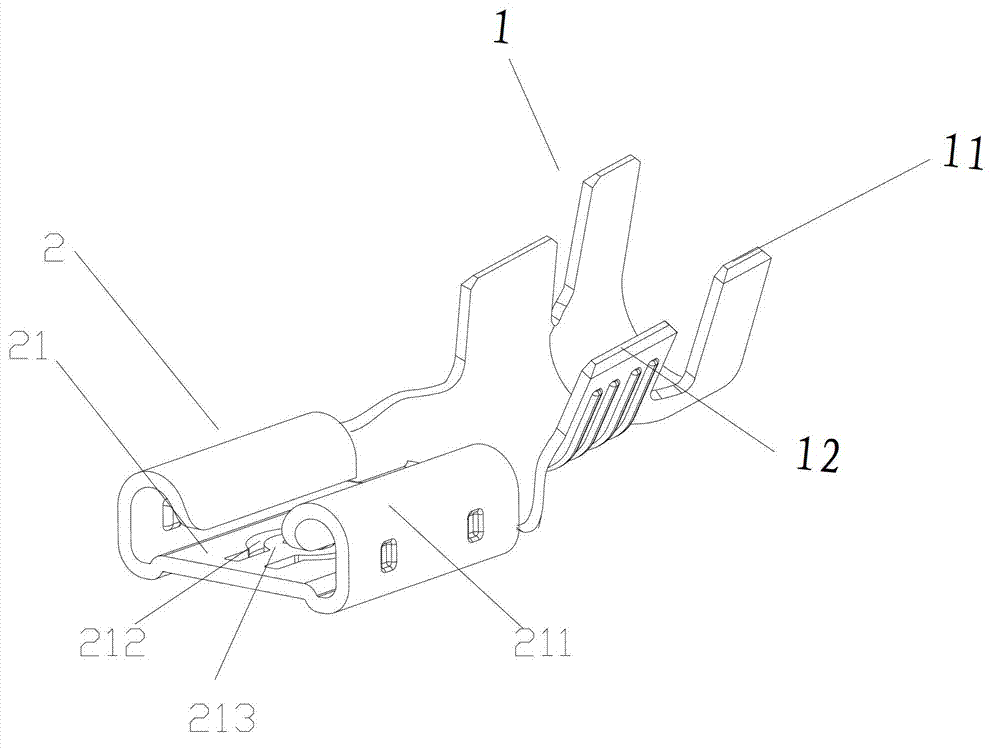

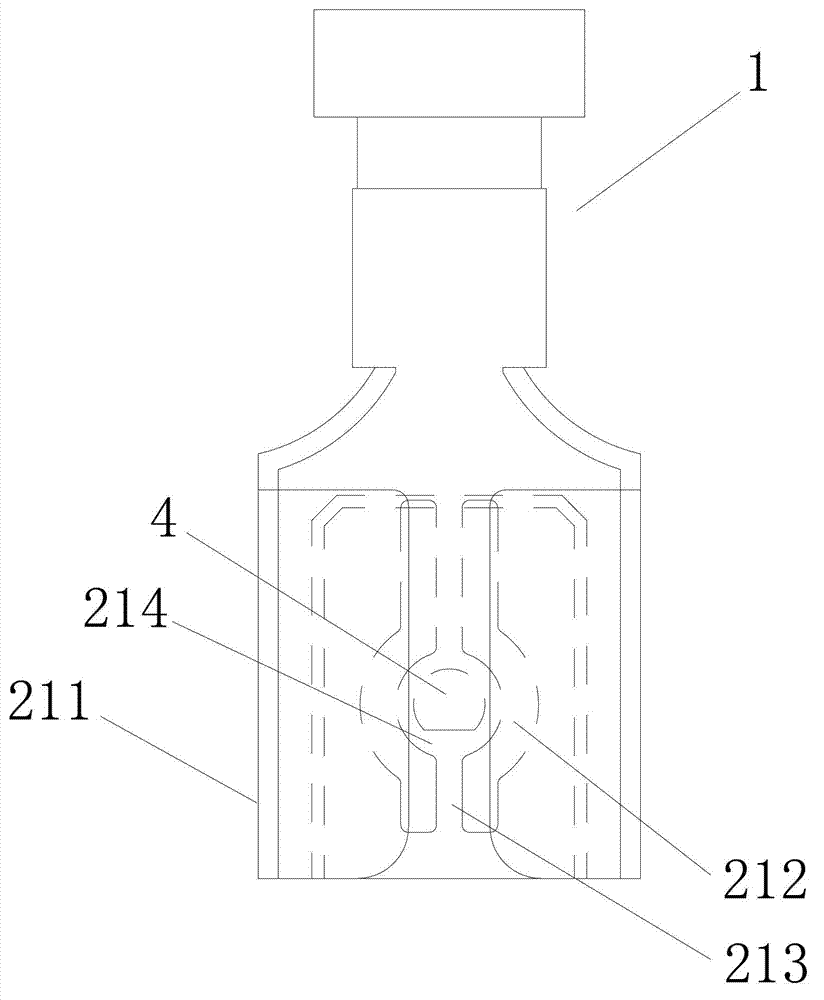

[0029] The structure of the in-line terminal described in the present invention is shown in figure 2 As shown, it includes a cable connection part 1 and a female terminal 2 connected in a straight line. The cable connecting part 1 is used for connecting cables, and generally includes a covering part 11 for wrapping the cable and a pressing part 12 for pressing the cable core. The female connection terminal 2 is used to connect a male connection terminal, such as a plug-in piece. The female terminal 2 includes a slot 21, the two sides of the slot 21 are arc-shaped tubular sidewalls 211, and the bottom of the slot 21 is formed with two slits 212, where the slits are arranged longitudinally, such as image 3 As shown, the width of the gap is set to 0.25mm. An elastic arm 213 is formed between the two slits 212, the length of the elastic arm 213 is 6 mm, and the width at both ends is 0.9 mm. The middle part of the elastic arm 213 is formed with a central expansion part 214, se...

Embodiment 2

[0032] On the basis of the in-line terminal described in the above embodiments, the inner wall of the arc-shaped tubular side wall 211 of the slot 21 may also be formed with a limited protrusion. The central expansion part 214 is provided with a locking protrusion 4, and the height of the locking protrusion 4 increases from one end close to the notch of the slot 21 to the other end, see image 3 .Such a structure has a smooth transition when inserting the male terminal, which is easy to insert, and has a groove structure when pulling out, so it is not easy to pull out, making the effect of low insertion force and high pull-out force more obvious. Further, on the bottom of the slot 21 and one end away from the notch of the slot 21, on the outside of the elastic arm 213, a blocking protrusion can also be provided, and the blocking protrusion can limit the connection of the male terminal. into depth.

[0033] The width of the elastic arm 213 of the in-line terminal in the prior ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com