LDMOS device with stepped multiple discontinuous filed plate and manufacturing method for LDMOS device

A stepped, field plate technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of single distance between the field plate and the device surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

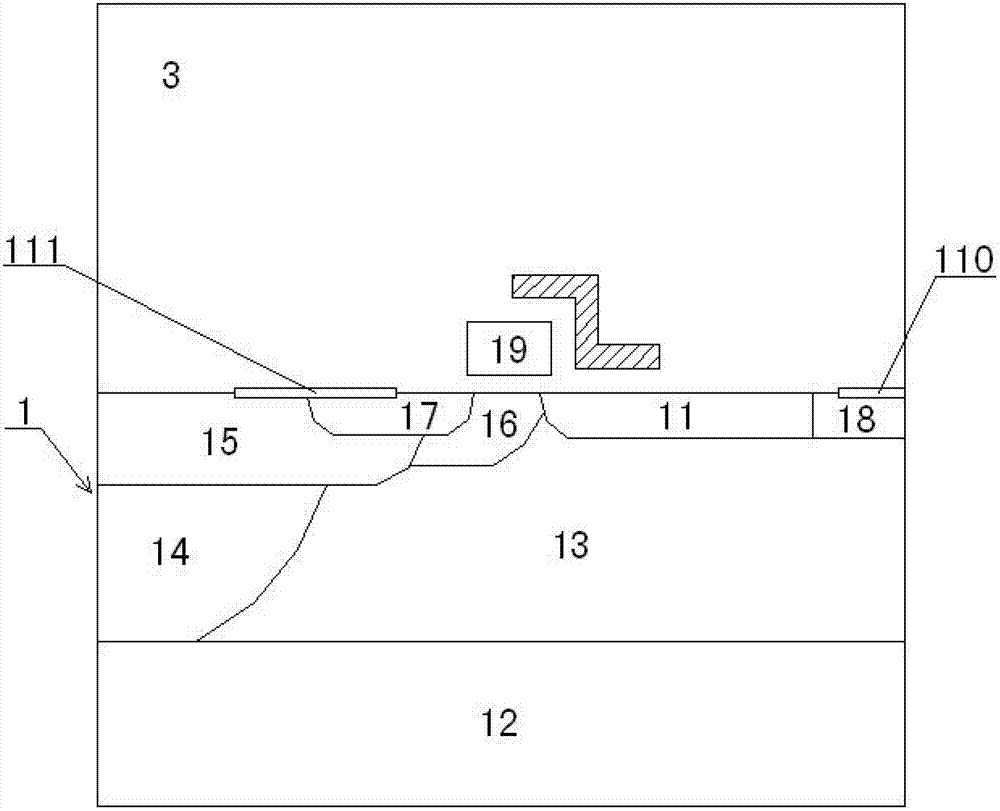

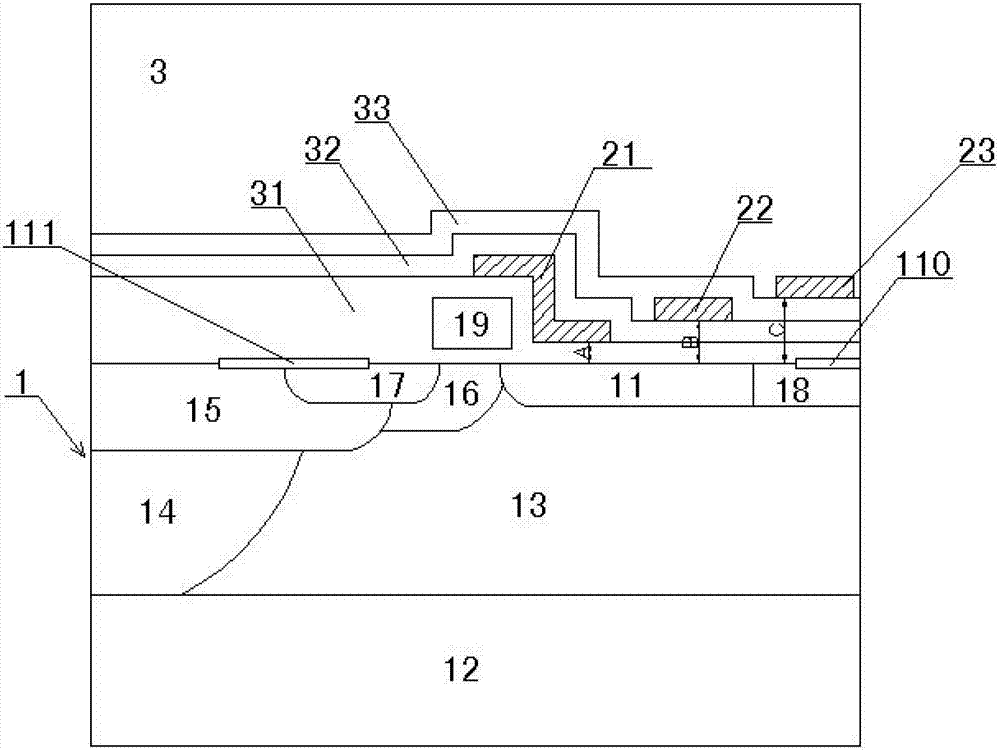

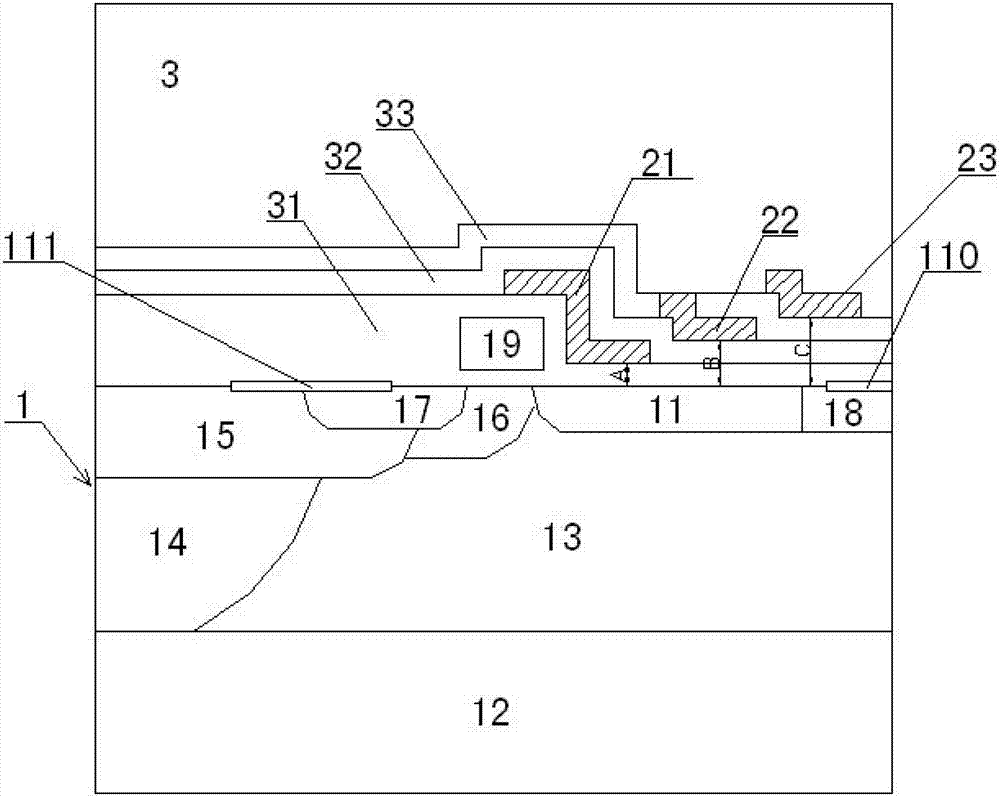

[0032] The structure of the LDMOS device with stepped multiple discontinuous field plates described in this embodiment is as follows figure 2 As shown, it includes a semiconductor body 1, the semiconductor body 1 includes a lowermost P-type heavily doped substrate 12, a P-type epitaxial layer 13 on the P-type heavily doped substrate 12, and an uppermost semiconductor dielectric layer 3 A P-type heavily doped source region 15, a P-type doped channel region 16, an N-type doped drain drift region 11 and an N-type heavily doped drain region 18 are formed between the P-type epitaxial layer 13 and the semiconductor dielectric layer 3 , where the P-type heavily doped source region 15 and the P-type doped channel region 16 are connected to form an N-type heavily doped source region 17 . Between the P-type heavily doped source region 15 and the P-type heavily doped substrate, a P-type doped connection or a trench 14 filled with a conductor is arranged, and the P-type doping in the tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com