Water tank for double-capacity water heater

A water heater water tank and double capacity technology, which is applied in the field of solar heat utilization, can solve the problems of high cost, large volume, thick insulation material, etc., and achieve the effect of saving materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

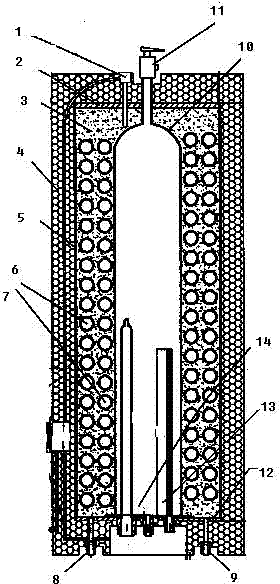

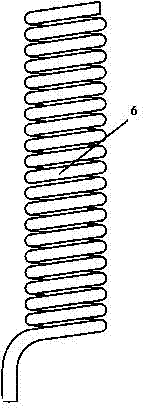

[0015] As shown in the figure: double capacity water heater tank, including temperature control probe 1, inner tank upper cover plate 2, phase change heat storage material (phase change heat capacity material) 3, foam material (insulation layer) 4, shell (plastic Inner tank) 5. The first and second heat exchangers (copper spiral coil) 6, 7, water inlet pipe 8, water outlet pipe 9, copper inner tank 10, pressure relief valve 11, inner tank lower cover plate 12, heating rod 13. The second water inlet pipe 14.

[0016] The phase change heat capacity material in the shell is uniformly surrounded and distributed on the first and second heat exchangers, both of which are metal heat exchangers, and the first and second heat exchangers can also use multiple Sheet-plate metal heat exchangers (in the case of a square tank structure, the plate-type metal heat exchangers of the first and second heat exchangers are alternately distributed); in the case of a round water tank, especially cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com