Process for constructing substrate dam of refuse dump

A technology for dumps and bases, which is applied in infrastructure engineering, construction, and sewage discharge, etc., and can solve problems such as poor drainage of dumps, weak bases, and insufficient strength of dumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

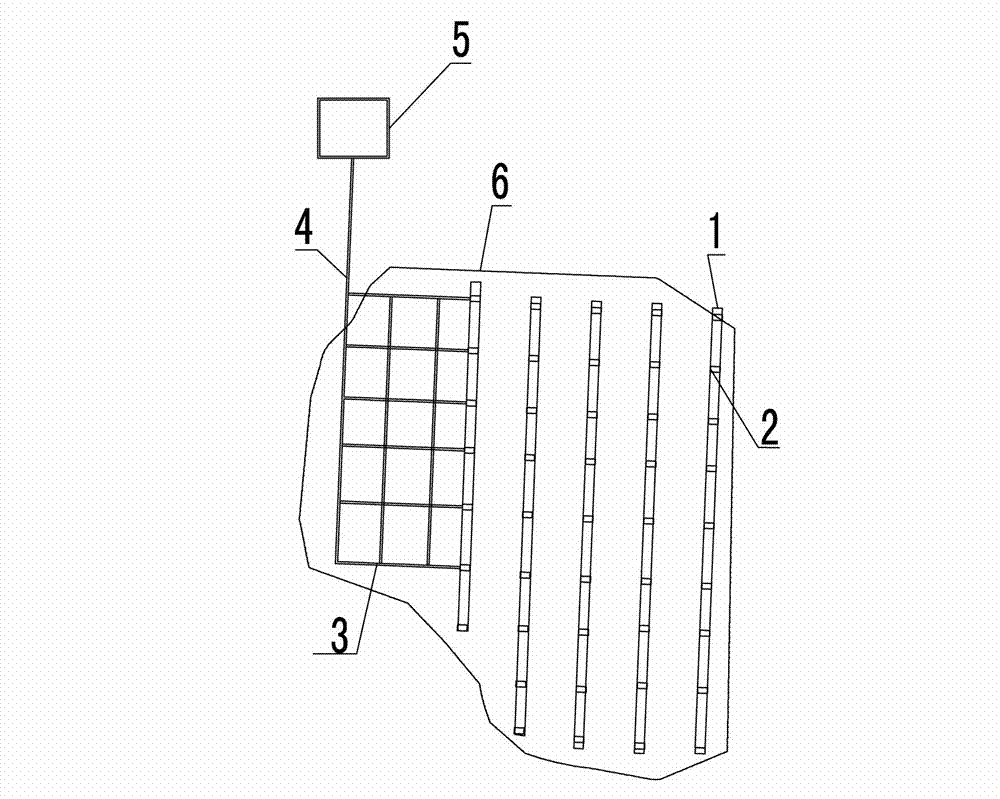

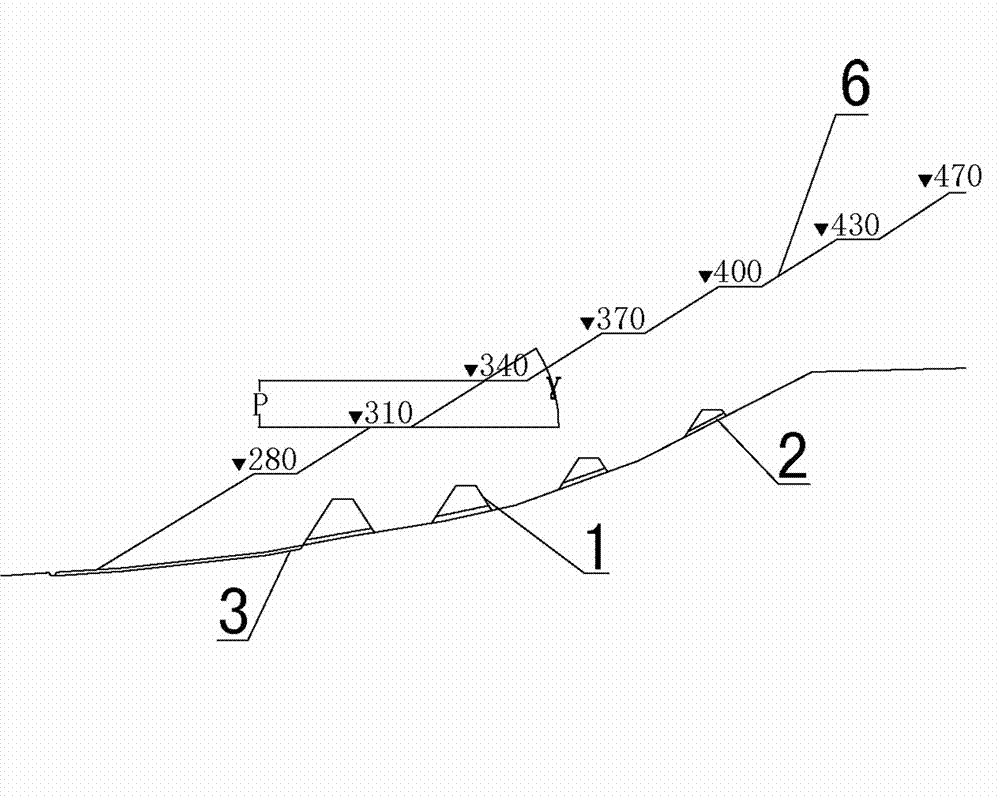

[0016] Such as figure 1 , 2 , Shown in 3, the foundation dam construction technology of the dump site of the present invention of the present invention may further comprise the steps:

[0017] 1) Within the scope of the dump, build a stepped base dam 1 vertically to the slope direction of the dump, and the distance and size between the base dams 1 are determined according to experience in dump operations.

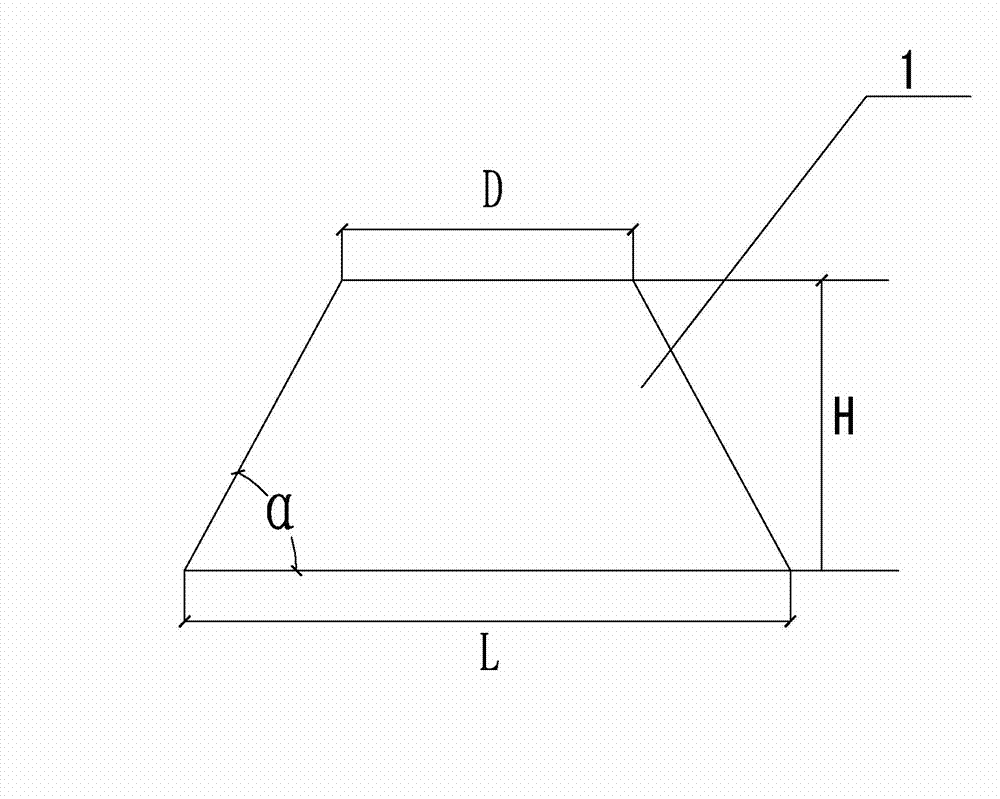

[0018] The base dam 1 of the present invention is formed by masonry of hard stones and concrete, and the base dam 1 is an isosceles trapezoid, forming a dump site where mining waste rock soil and solidified tailings are combined and mixed;

[0019] 2) Set drainage hole 2 at the foundation of base dam 1, and dig drainage ditch 3 at the drainage hole 2 of the base dam at the lowest elevation,

[0020] 3) Excavate a drainage ditch 4 between the drainage ditch 3 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com